This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

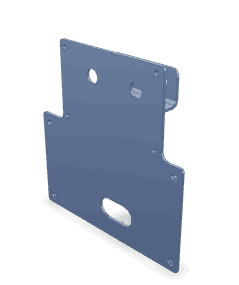

The 4304704 Electronic Control Module (ECM) Bracket, manufactured by Cummins, is a component designed to support and protect the ECM in commercial trucks. Cummins, a well-established name in the automotive industry, particularly in diesel engine manufacturing, produces this bracket to enhance the reliability and functionality of truck electronic systems.

Basic Concepts of Electronic Control Module Brackets

An Electronic Control Module (ECM) Bracket serves as a mounting and protective structure for the ECM within a truck’s electronic system. It facilitates the secure attachment of the ECM to the vehicle, ensuring stability and protection against physical damage. Additionally, the bracket plays a role in interfacing the ECM with other electronic components, contributing to the overall efficiency and reliability of the truck’s electronic system 1.

Purpose of the 4304704 Electronic Control Module Bracket

The 4304704 ECM Bracket is designed to support and protect the ECM in commercial trucks. It contributes to the ECM’s functionality by providing a stable and secure mounting point, which is crucial for the ECM’s operation. The bracket also offers protection against environmental factors and physical impacts, ensuring the ECM remains operational under various conditions 2.

Key Features

The 4304704 ECM Bracket is constructed from durable materials, ensuring longevity and resilience in demanding environments. Its design includes features that enhance its performance, such as precise mounting points for secure attachment and protective elements that shield the ECM from external factors. The bracket’s construction and design are tailored to meet the specific requirements of commercial truck applications, ensuring compatibility and effectiveness.

Benefits

The 4304704 ECM Bracket offers several benefits, including enhanced protection for the ECM, which contributes to the overall reliability of the truck’s electronic system. By securing the ECM in place and shielding it from potential damage, the bracket helps maintain system integrity and performance. Additionally, the bracket’s design and construction contribute to the longevity of the ECM, reducing the need for frequent replacements and maintenance.

Installation Considerations

Proper installation of the 4304704 ECM Bracket is crucial for its effectiveness. It is important to ensure compatibility with the specific truck model to guarantee a secure fit and optimal performance. Correct placement and securing of the bracket are necessary to protect the ECM and ensure the bracket’s structural integrity. Following manufacturer guidelines during installation will help achieve the best results.

Troubleshooting and Maintenance

Regular maintenance of the 4304704 ECM Bracket can help ensure its longevity and optimal performance. Inspecting the bracket for signs of wear or damage and addressing any issues promptly can prevent potential problems. Common troubleshooting steps include checking the bracket’s securement and ensuring it remains free from obstructions that could interfere with the ECM’s operation.

Role in Truck Diagnostics

The 4304704 ECM Bracket plays a role in the diagnostic process by facilitating access to the ECM for diagnostic procedures and data retrieval. Its design allows for easy removal and reinstallation, which is beneficial during diagnostic and maintenance operations. This accessibility ensures that technicians can efficiently perform diagnostics and make necessary adjustments or repairs.

Environmental and Operational Resilience

The 4304704 ECM Bracket is designed to withstand various environmental conditions and operational stresses. Its construction materials and design features are chosen to provide resilience against factors such as temperature fluctuations, moisture, and physical impacts. This ensures that the ECM remains protected and operational under diverse driving conditions, contributing to the truck’s overall performance and reliability.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the automotive industry, with a strong history and expertise in diesel engine manufacturing. The company is committed to innovation and quality, consistently delivering products that meet the high demands of commercial and industrial applications. Cummins’ reputation for reliability and performance is reflected in its wide range of products, including the 4304704 ECM Bracket, which is designed to enhance the functionality and protection of electronic systems in commercial trucks 3.

Compatibility with Engine Models

The Electronic Control Module (ECM) Bracket part 4304704 by Cummins is designed to be compatible with several engine models. This bracket is essential for securing the ECM in place, ensuring that the electronic control unit is properly mounted and protected within the engine compartment.

For the G855 CM558 and GTA855 CM558 (CM2358) G101 engines, the ECM Bracket part 4304704 is engineered to fit seamlessly into the engine’s architecture. This bracket provides a stable mounting point for the ECM, which is critical for the engine’s electronic control systems to function correctly.

Similarly, the N14 G engine also utilizes the ECM Bracket part 4304704. This bracket ensures that the ECM is securely fastened, allowing for reliable operation of the engine’s electronic systems. The design of the bracket is such that it can accommodate the specific layout and requirements of the N14 G engine, ensuring a precise fit and function.

In summary, the ECM Bracket part 4304704 is a versatile component that is compatible with the G855 CM558, GTA855 CM558 (CM2358) G101, and N14 G engines. Its design ensures that the ECM is securely mounted, which is crucial for the proper functioning of the engine’s electronic control systems.

Role of Part 4304704 Electronic Control Module Bracket in Engine Systems

The Electronic Control Module (ECM) Bracket, identified by part number 4304704, is an essential component in the assembly and functionality of modern engine systems. This bracket securely mounts the ECM, ensuring it remains stable and protected within the engine compartment.

When integrating the ECM Bracket with an Electronic Control Module Kit, it provides a robust foundation for the module. This setup is vital for the module’s operation, as it houses the primary brain of the engine control system, responsible for processing data from various sensors and executing commands to the actuators.

In conjunction with the Engine Control System, the ECM Bracket ensures that the module is positioned optimally for efficient thermal management and access to necessary connections. This integration allows for seamless communication between the ECM and other critical components, such as the fuel injectors, throttle body, and exhaust gas recirculation valve.

The Ignition System also benefits from the precise mounting provided by the ECM Bracket. Accurate placement of the ECM ensures reliable signal transmission to the ignition coils, promoting consistent spark delivery and combustion efficiency.

Overall, the ECM Bracket plays a significant role in maintaining the structural integrity and operational efficiency of the engine system by ensuring the ECM is securely and correctly installed.

Conclusion

The 4304704 ECM Bracket by Cummins is a critical component for the protection and functionality of the ECM in commercial trucks. Its durable construction, precise design, and compatibility with various engine models make it an essential part of modern engine systems. Proper installation, regular maintenance, and understanding its role in diagnostics and environmental resilience are key to maximizing the benefits of this Cummins part.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins official website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.