This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

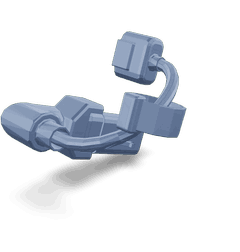

The 4302948 Electronic Control Module Wiring Harness, manufactured by Cummins, is a vital component in the operation of commercial trucks. This wiring harness facilitates the communication between the Electronic Control Module (ECM) and various electrical components within the truck, ensuring efficient and reliable performance.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that transmit electrical signals between the ECM and other components in a truck’s electrical system. It consists of insulated wires, connectors, terminals, and sometimes fuses or relays. The harness plays a role in the electrical system by providing a structured pathway for signals and power, ensuring that all components receive the necessary inputs to function correctly 1.

Purpose of the 4302948 Electronic Control Module Wiring Harness

The 4302948 Electronic Control Module Wiring Harness is designed to facilitate the interaction between the ECM and other electrical components in a truck. It ensures that the ECM can send and receive signals accurately, allowing for precise control over engine functions, transmission operations, and other critical systems. This interaction is fundamental to the truck’s overall performance and efficiency 2.

Key Features

The 4302948 Electronic Control Module Wiring Harness features a robust design that includes high-quality materials to enhance its performance and durability. It is constructed with durable insulation to protect the wires from environmental factors and mechanical stress. The harness also incorporates precise connectors and terminals to ensure secure and reliable connections. Additionally, it is designed to withstand the harsh conditions often encountered in commercial trucking, such as vibrations, temperature fluctuations, and exposure to chemicals 3.

Benefits

The 4302948 Electronic Control Module Wiring Harness offers several advantages. It contributes to improved engine performance by ensuring that the ECM receives accurate data from various sensors and can send precise commands to actuators. This results in optimized fuel efficiency and reduced emissions. The harness also enhances the reliability of the truck’s electrical system, minimizing the risk of malfunctions. Furthermore, it simplifies diagnostics by providing a structured pathway for signals, making it easier to identify and resolve issues 4.

Installation Process

Installing the 4302948 Electronic Control Module Wiring Harness requires careful attention to detail. Begin by ensuring the truck is turned off and the battery is disconnected to prevent electrical shocks. Use appropriate tools, such as wire strippers and crimping tools, to prepare the wires and connectors. Follow the manufacturer’s instructions to route the harness through the truck, securing it with ties or clips to prevent damage from vibrations. Finally, reconnect the battery and test the system to ensure all connections are secure and functioning correctly.

Troubleshooting Common Issues

Common issues with the 4302948 Electronic Control Module Wiring Harness may include loose connections, damaged wires, or faulty connectors. To troubleshoot these problems, begin by inspecting the harness for any visible signs of damage. Use a multimeter to test the continuity of the wires and ensure that all connections are secure. If a faulty component is identified, replace it with a compatible part. Regular inspections can help prevent many issues from arising.

Maintenance Tips

To ensure the longevity and optimal performance of the 4302948 Electronic Control Module Wiring Harness, regular maintenance is recommended. Inspect the harness at regular intervals for signs of wear or damage. Clean the connectors and terminals to remove any corrosion or debris that may affect their performance. Ensure that the harness is properly secured and protected from environmental factors. Following these maintenance tips can help prevent issues and extend the life of the wiring harness.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products, including diesel and natural gas engines, as well as related technologies such as emissions solutions and aftermarket services. Cummins is committed to providing reliable and efficient power solutions for its customers.

Cummins Electronic Control Module Wiring Harness (Part 4302948)

The Cummins Electronic Control Module (ECM) Wiring Harness, identified by part number 4302948, is a critical component in the electrical system of various Cummins engines. This wiring harness is designed to ensure seamless communication between the ECM and other electronic control units (ECUs) within the engine system. It is engineered to withstand the rigors of engine operation, providing reliable connectivity and data transfer.

Compatibility with Cummins Engines

The ECM Wiring Harness 4302948 is compatible with several Cummins engine models, including:

-

QSK19: This engine is known for its robust performance and reliability in heavy-duty applications. The wiring harness ensures that the ECM can effectively manage engine functions, optimizing performance and efficiency.

-

CM2350: This engine is typically used in medium-duty applications, offering a balance of power and fuel efficiency. The wiring harness is crucial for maintaining the integrity of the ECM’s control over engine operations, ensuring smooth and reliable performance.

-

K105: This engine is part of the K Series, which is widely used in various industrial and commercial applications. The wiring harness is essential for the proper functioning of the ECM, ensuring that all electronic components communicate effectively.

The ECM Wiring Harness 4302948 is designed to fit these engines by providing a secure and reliable connection between the ECM and other electronic components. It is engineered to handle the electrical demands of the engine, ensuring that data is transmitted accurately and efficiently. This wiring harness is a vital part of the engine’s electrical system, contributing to the overall performance and reliability of the engine.

Role of Part 4302948 Electronic Control Module Wiring Harness in Engine Systems

The part 4302948 Electronic Control Module (ECM) Wiring Harness is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the transmission of electrical signals that are essential for engine management and performance.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects to a multitude of sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. These sensors provide real-time data to the ECM about the engine’s operating conditions, allowing for precise control of fuel injection, ignition timing, and emissions.

-

Actuators: It interfaces with actuators including the fuel injectors, throttle body, and various solenoids. The harness transmits commands from the ECM to these components, enabling dynamic adjustments to fuel delivery and air intake based on sensor inputs and driving conditions.

-

Ignition System: The harness is responsible for connecting the ECM to the ignition coils. It ensures that the timing of spark delivery to the cylinders is accurately controlled, which is fundamental for efficient combustion and engine performance.

-

Emission Control Systems: It links the ECM to components of the emission control system, such as the Exhaust Gas Recirculation (EGR) valve and the catalytic converter. This connection allows the ECM to monitor and adjust these systems to minimize harmful emissions while maintaining engine efficiency.

-

Power Supply: The harness also provides the necessary power supply to the ECM and other electronic components, ensuring they operate within specified parameters.

-

Communication Networks: In more advanced engine systems, the ECM Wiring Harness may also connect to the vehicle’s onboard communication network (such as CAN bus), allowing the ECM to share data with other control modules for integrated vehicle management.

In summary, the part 4302948 ECM Wiring Harness is a cornerstone of the engine’s electronic system, ensuring seamless communication and control between the ECM and a wide array of engine components. Its role is fundamental in achieving optimal engine performance, efficiency, and compliance with emission standards.

Conclusion

The 4302948 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks and Cummins engines. It ensures seamless communication between the ECM and various engine components, contributing to optimal engine performance, efficiency, and compliance with emission standards. Regular maintenance and proper installation are essential to ensure the longevity and reliability of this Cummins part.

-

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 4310735, ISX15 CM2250 SN.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.