This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

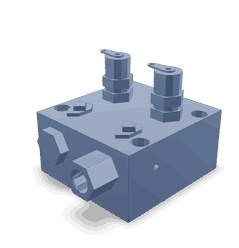

The 4099179 Terminal Block is a component manufactured by Cummins, a well-established name in the commercial truck industry. This terminal block holds significance within the electrical systems of commercial trucks, contributing to the efficient management and distribution of electrical power.

Basic Concepts of Terminal Blocks

Terminal blocks are devices used in electrical systems to connect wires and circuits. They provide a secure and organized method for routing and terminating electrical wires, facilitating the transfer of electrical signals and power between different components within a system. Terminal blocks come in various designs and configurations to accommodate different wiring needs and environmental conditions 1.

Purpose of the 4099179 Terminal Block

The 4099179 Terminal Block plays a role in the operation of a truck by managing and distributing electrical power. It serves as a junction point where multiple wires can be connected, allowing for the efficient routing of electrical signals and power throughout the truck’s electrical system. This component ensures that electrical connections are secure and organized, contributing to the overall reliability and performance of the truck’s electrical network.

Key Features

The 4099179 Terminal Block is designed with specific features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to corrosion and wear, ensuring long-lasting reliability in demanding environments. The terminal block’s design includes features such as secure wire clamping mechanisms and clear labeling for easy identification of connections, contributing to efficient installation and maintenance.

Benefits

The 4099179 Terminal Block offers several advantages, including improved electrical efficiency, ease of installation, and maintenance benefits. Its design allows for quick and secure wire connections, reducing the risk of loose connections that can lead to electrical issues. Additionally, the terminal block’s durable construction and corrosion-resistant materials contribute to its longevity and reliable performance, minimizing the need for frequent replacements or repairs.

Installation Process

Installing the 4099179 Terminal Block involves several steps to ensure proper connection and functionality. Begin by identifying the location where the terminal block will be installed and prepare the necessary tools, such as wire strippers and a screwdriver. Follow the manufacturer’s instructions for stripping and inserting wires into the terminal block, ensuring that connections are secure and properly tightened. Take care to observe any precautions outlined in the installation guide to avoid damage to the terminal block or surrounding components.

Troubleshooting Common Issues

Common issues that may arise with terminal blocks include loose connections, corrosion, or damaged wires. To troubleshoot these problems, inspect the terminal block for signs of wear or corrosion and ensure that all connections are secure and properly tightened. If corrosion is present, clean the affected areas using appropriate cleaning solutions and re-tighten connections as needed. In cases of damaged wires, replace the affected wires to restore proper functionality.

Maintenance Tips

Regular maintenance practices can help ensure the longevity and reliable performance of the 4099179 Terminal Block. Inspect the terminal block periodically for signs of wear, corrosion, or loose connections. Clean the terminal block and surrounding areas to remove any dirt or debris that may accumulate over time. Additionally, verify that all connections are secure and properly tightened to prevent electrical issues.

Safety Considerations

When working with terminal blocks, it is important to observe electrical safety practices and proper handling procedures. Ensure that the power is disconnected before beginning any work on the terminal block to avoid the risk of electrical shock. Use appropriate personal protective equipment, such as insulated gloves and safety glasses, when handling electrical components. Follow all manufacturer guidelines and safety instructions to ensure a safe working environment.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the commercial truck industry. Known for its commitment to quality and innovation, Cummins produces a wide range of components designed to meet the demanding requirements of commercial trucks. The company’s reputation for reliability and performance has earned it a strong presence in the industry, making it a trusted choice for truck owners and operators 2.

Cummins Terminal Block 4099179 in Engine Applications

The Cummins Terminal Block 4099179 is a critical component in the electrical systems of various Cummins engines. This part is integral to the proper functioning of the engine’s electrical architecture, ensuring reliable and efficient power distribution.

QSK19

In the QSK19 engine, the Terminal Block 4099179 serves as a junction point for multiple electrical connections. It facilitates the integration of various sensors, control units, and other electrical components, ensuring seamless communication and power flow within the engine’s electrical system.

CM850

For the CM850 engine, the Terminal Block 4099179 is designed to handle the high electrical demands typical of this model. It provides a robust and organized interface for connecting multiple electrical circuits, ensuring that the engine’s control systems operate efficiently and reliably.

MCRS

In the MCRS engine, the Terminal Block 4099179 is engineered to meet the stringent requirements of marine applications. It ensures that all electrical connections are secure and reliable, even in harsh marine environments. This part is crucial for maintaining the integrity of the engine’s electrical system, which is essential for the safe and efficient operation of marine vessels.

Grouped Applications

The Terminal Block 4099179 is also used in other Cummins engines, where it provides similar functionality. It is designed to be versatile and reliable, ensuring that the engine’s electrical system operates smoothly and efficiently. This part is a testament to Cummins’ commitment to quality and reliability in their engine components.

Role of Part 4099179 Terminal Block in Engine Systems

The part 4099179 Terminal Block is an essential component in the electrical architecture of engine systems. It serves as a central junction point for various electrical connections, facilitating the distribution of power and signals throughout the system.

In the context of an alarm system, the Terminal Block ensures that the alarm circuit is properly connected and grounded. This allows for reliable operation of the alarm, providing timely notifications of any irregularities within the engine system.

When integrated with a sensor bracket, the Terminal Block plays a key role in managing the electrical connections for sensors. These sensors are responsible for monitoring various parameters such as temperature, pressure, and other critical metrics. The Terminal Block ensures that these sensors receive the necessary power and that their signals are accurately transmitted to the engine monitoring system.

Within the engine monitoring system, the Terminal Block is instrumental in organizing the myriad of electrical connections required for comprehensive engine diagnostics. It allows for the efficient routing of data from multiple sensors to the monitoring unit, enabling real-time analysis and feedback.

Overall, the part 4099179 Terminal Block enhances the reliability and efficiency of electrical connections in engine systems, supporting the seamless operation of alarms, sensors, and monitoring units.

Conclusion

The 4099179 Terminal Block is a vital component in the electrical systems of Cummins engines, ensuring reliable and efficient power distribution. Its design and features contribute to the overall performance and durability of the engine’s electrical architecture. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.