This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

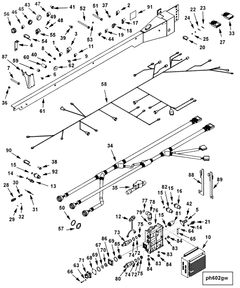

The Electronic Control Module Wiring Harness (Part #4086083) by Cummins is a critical component in the operation of heavy-duty trucks. This wiring harness is designed to facilitate communication between the Electronic Control Module (ECM) and various other components within the truck. Cummins, a renowned manufacturer in the automotive industry, produces this part with a focus on reliability and performance.

Basic Concepts

The Electronic Control Module (ECM) serves as the brain of the truck, managing and regulating various operations to ensure optimal performance. It processes data from sensors and other components, making real-time adjustments to enhance efficiency and safety. The wiring harness plays a role in this system by providing the necessary connections between the ECM and other components, ensuring seamless data transmission and operation 1.

Purpose of the Electronic Control Module Wiring Harness

The Electronic Control Module Wiring Harness is integral to the operation of a truck. It facilitates communication between the ECM and other truck components, allowing for the efficient transmission of data and signals. This ensures that the ECM can make informed decisions and adjustments, contributing to the overall performance and reliability of the truck.

Key Features

The Electronic Control Module Wiring Harness is characterized by its robust design and high-quality materials. It is engineered to withstand the demanding conditions of heavy-duty truck operations, ensuring durability and longevity. The harness is designed with precision to provide secure and reliable connections, enhancing the performance and efficiency of the truck.

Benefits

Utilizing the Electronic Control Module Wiring Harness offers several advantages. It contributes to improved reliability by ensuring secure and consistent connections between the ECM and other components. This enhances the overall performance of the truck, allowing for more efficient operation. Additionally, the harness is designed for easier maintenance, reducing downtime and facilitating quicker repairs when necessary.

Installation Process

Installing the Electronic Control Module Wiring Harness involves several steps. Begin by ensuring the truck is turned off and the battery is disconnected to prevent any electrical accidents. Locate the existing wiring harness and carefully disconnect it from the ECM and other components. Align the Electronic Control Module Wiring Harness with the connection points and secure it in place. Reconnect the battery and test the system to ensure proper installation.

Common Issues and Troubleshooting

Common issues with the Electronic Control Module Wiring Harness may include loose connections, damaged wires, or faulty components. To troubleshoot, begin by inspecting the harness for any visible damage or loose connections. If issues are detected, carefully repair or replace the affected sections. If the problem persists, it may be necessary to consult a professional for further diagnosis and repair.

Maintenance Tips

Regular maintenance of the Electronic Control Module Wiring Harness is crucial for ensuring its longevity and optimal performance. Inspect the harness regularly for any signs of wear, damage, or loose connections. Clean the harness to remove any dirt or debris that may affect its performance. Address any issues promptly to prevent further damage and ensure the continued reliability of the truck.

Cummins Overview

Cummins is a well-established manufacturer with a rich history in the automotive industry. The company is renowned for its high-quality components, particularly for heavy-duty trucks. Cummins is committed to innovation and excellence, producing parts that are designed to enhance the performance, reliability, and efficiency of vehicles. The Electronic Control Module Wiring Harness is a testament to Cummins’ dedication to quality and performance in the automotive sector.

Compatibility with Cummins Engines

The Electronic Control Module (ECM) Wiring Harness, identified by part number 4086083, is a critical component in the electrical architecture of various Cummins engines. This wiring harness is designed to facilitate the transmission of electrical signals between the ECM and other electronic control units within the engine system.

For the QSK45 CM500 and QSK60 CM500 engines, the ECM Wiring Harness ensures seamless communication between the ECM and the engine’s various sensors and actuators. This is crucial for maintaining optimal engine performance and efficiency.

The QSK60G engine also utilizes the ECM Wiring Harness, which is tailored to meet the specific electrical requirements of this model. The harness is engineered to withstand the operational stresses of the engine, ensuring reliable signal transmission under varying conditions.

Similarly, the QSK78 CM500 engine incorporates the ECM Wiring Harness, which is integral to its electronic control system. This harness is designed to interface with the ECM and other electronic components, ensuring that the engine operates smoothly and efficiently.

In summary, the ECM Wiring Harness (part number 4086083) is a vital component for the QSK45 CM500, QSK60 CM500, QSK60G, and QSK78 CM500 engines, facilitating essential electrical communication within the engine system.

Role of the Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness is an integral component in the orchestration of various engine systems. It serves as the primary conduit for electrical signals between the ECM and other engine components, ensuring seamless communication and operation.

Integration with the Main Extension Harness

The ECM Wiring Harness interfaces with the Main Extension Harness, which extends the reach of the ECM to various sensors and actuators distributed throughout the engine system. This connection allows for the transmission of diagnostic data and control signals, facilitating real-time monitoring and adjustment of engine performance.

Connection to the Engine Control Module

At the heart of the engine’s electronic system lies the Engine Control Module (ECM). The ECM Wiring Harness is directly connected to the ECM, providing it with the necessary power and ground connections. It also routes signals from the ECM to other components, enabling the ECM to execute its role in managing fuel injection, ignition timing, and emissions control.

Interaction with Engine Control Components

The harness plays a pivotal role in linking the ECM with various engine control components. These include:

- Sensors: Such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. The harness transmits data from these sensors to the ECM, allowing for precise control of the air-fuel mixture.

- Actuators: Including the fuel injectors, idle air control (IAC) valve, and throttle position actuator. The harness conveys commands from the ECM to these actuators, ensuring they operate in accordance with the ECM’s calculations.

Mounting and Structural Considerations

The ECM Wiring Harness is designed with mounting points that allow it to be securely fastened within the engine compartment. This not only protects the harness from physical damage but also ensures it remains in the optimal position for signal transmission. The harness’s routing is carefully planned to avoid interference with moving parts and to minimize the risk of chafing or abrasion.

Enhancing System Reliability

By providing a dedicated pathway for electrical signals, the ECM Wiring Harness enhances the reliability of the engine’s electronic systems. It reduces the likelihood of signal interference and ensures that the ECM receives accurate data from sensors and can effectively control actuators. This contributes to the overall stability and efficiency of the engine’s operation 2.

Conclusion

The Electronic Control Module Wiring Harness (Part #4086083) by Cummins is a critical component for the reliable and efficient operation of heavy-duty trucks. Its robust design, high-quality materials, and precise engineering ensure secure and reliable connections between the ECM and other components. Regular maintenance and proper installation are essential for maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.