This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

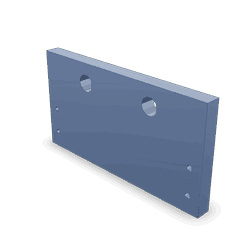

The Electronic Control Module Bracket (Part #4022856) by Cummins is a component designed to support and secure the Electronic Control Module (ECM) in commercial trucks. Cummins Inc., a well-established manufacturer in the commercial truck industry, produces this bracket. The ECM Bracket is significant as it ensures the ECM remains in place and is protected from potential damage, contributing to the overall reliability and performance of the truck 1.

Basic Concepts

The Electronic Control Module (ECM) is a vital component in modern trucks, responsible for managing various engine functions and ensuring optimal performance. The ECM Bracket plays a role in securing and protecting the ECM by providing a stable mounting point. This bracket helps to shield the ECM from vibrations, impacts, and environmental factors that could otherwise compromise its functionality 2.

Purpose and Functionality

The ECM Bracket serves to maintain the ECM’s position and integrity within the truck. By securely holding the ECM in place, the bracket helps to prevent movement that could lead to connection issues or damage to the module. This stability is crucial for the ECM to perform its role effectively, which includes monitoring and controlling engine operations, fuel injection, emissions, and other critical systems 3.

Key Features

The ECM Bracket by Cummins is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operations. Key features include a robust design that offers excellent protection for the ECM, precise mounting points for secure installation, and corrosion-resistant properties to enhance longevity. These attributes contribute to the bracket’s performance and durability in various operating conditions.

Benefits

The ECM Bracket provides several benefits, including improved protection for the ECM, which leads to enhanced truck performance and reliability. By securing the ECM firmly in place, the bracket helps to ensure that the module operates within specified parameters, reducing the risk of malfunctions. Additionally, the bracket’s design contributes to the overall durability of the ECM, making it more resistant to wear and environmental factors.

Installation and Compatibility

Proper installation of the ECM Bracket is crucial to ensure it functions as intended. Guidelines for installation include verifying compatibility with specific truck models and ECM types to ensure a proper fit. Following manufacturer recommendations for mounting and securing the bracket will help to maintain the integrity of the ECM and the overall performance of the truck.

Troubleshooting and Maintenance

Common issues related to the ECM Bracket may include loose connections, damage from impacts, or corrosion. Regular maintenance checks can help identify signs of wear or damage early, allowing for timely repairs or replacements. Maintenance tips include inspecting the bracket for any signs of corrosion, ensuring all mounting points are secure, and verifying that the ECM remains properly seated.

Safety Considerations

When handling and installing the ECM Bracket, it is important to follow safety practices to prevent injury and ensure proper functionality. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and the ECM is disconnected before beginning any work, and following all manufacturer guidelines for installation and maintenance.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. With a history of innovation and commitment to customer satisfaction, Cummins continues to be a trusted name in the production of engine components and systems, including the ECM Bracket.

Engine Compatibility for Electronic Control Module Bracket (Part 4022856)

The Electronic Control Module (ECM) Bracket, identified by part number 4022856 and manufactured by Cummins, is a crucial component in the installation and operation of the ECM in various engine configurations. This bracket ensures the ECM is securely mounted, providing stability and protection for the sensitive electronic components.

M11 CELECT PLUS and M11 MECHANICAL Engines

The 4022856 ECM Bracket is specifically designed to fit seamlessly with both the M11 CELECT PLUS and M11 MECHANICAL engines. These engines, while differing in their control systems, share a common platform that allows for the interchangeability of certain components, including the ECM Bracket.

-

M11 CELECT PLUS Engine: This engine variant utilizes advanced electronic controls for enhanced performance and efficiency. The ECM Bracket in this context ensures that the ECM is properly aligned and secured, facilitating optimal communication between the engine’s electronic systems and the control module.

-

M11 MECHANICAL Engine: In contrast, the M11 MECHANICAL engine relies on traditional mechanical controls. Despite this difference, the ECM Bracket’s role remains consistent—to provide a reliable mounting solution for the ECM, ensuring it is positioned correctly within the engine bay.

The design of the 4022856 ECM Bracket is engineered to accommodate the specific mounting points and spatial requirements of both engine types, ensuring a secure fit and reliable performance. This compatibility allows for ease of maintenance and repair, as the same bracket can be used across different engine configurations, reducing the need for multiple spare parts.

Role of Part 4022856 Electronic Control Module Bracket in Engine Systems

The Electronic Control Module (ECM) Bracket, identified by part number 4022856, serves as a foundational component in the integration and operation of various engine systems. Its primary function is to securely mount the ECM, ensuring stability and proper positioning within the engine compartment.

Integration with the Electronic Control Module Kit

When installed, the ECM Bracket supports the Electronic Control Module Kit, which includes the ECM itself along with associated sensors and wiring harnesses. This bracket ensures that the ECM remains firmly in place, reducing the risk of damage from vibrations or impacts. Proper mounting is essential for the ECM to effectively manage engine operations, including fuel injection, ignition timing, and emissions control.

Interface with Engine Systems

The ECM Bracket facilitates the interface between the ECM and other engine components. It allows for the secure attachment of wiring harnesses that connect the ECM to sensors and actuators throughout the engine system. This interface is vital for the ECM to receive data from various sensors (such as the oxygen sensor, throttle position sensor, and crankshaft position sensor) and send commands to actuators (like fuel injectors and ignition coils).

Role in Step Time Control

In systems that require precise Step Time Control, the ECM Bracket plays a significant role. Step Time Control refers to the timing of fuel injection and ignition events, which must be meticulously coordinated for optimal engine performance and efficiency. The ECM, mounted on the bracket, processes input data and adjusts the timing of these events in real-time. The stability provided by the bracket ensures that the ECM can operate without interference, maintaining the accuracy of Step Time Control.

Summary of Component Interaction

- ECM Kit: The bracket supports the ECM and associated components, ensuring they are securely mounted.

- Interface: It enables the connection between the ECM and various engine sensors and actuators.

- Step Time Control: Ensures the ECM can accurately manage the timing of fuel injection and ignition events.

The ECM Bracket is an integral part of the engine system, contributing to the reliable operation of the ECM and, by extension, the overall performance of the engine.

Conclusion

The Electronic Control Module Bracket (Part #4022856) by Cummins is a critical component in the operation and maintenance of commercial truck engines. Its role in securing and protecting the ECM ensures the reliable performance of the engine system. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.