3822920

Electrical Connector Repair Terminal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Electrical Connector Repair Terminal 3822920 is a specialized component designed for the maintenance and repair of electrical connections in heavy-duty trucks. It facilitates the restoration and upkeep of electrical systems, ensuring they operate efficiently and reliably. This terminal plays a significant role in heavy-duty truck maintenance by providing a reliable solution for repairing damaged or worn electrical connectors, thereby contributing to the overall performance and safety of the vehicle 1.

Basic Concepts

Electrical connectors and terminals in heavy-duty trucks are vital for ensuring reliable electrical connections across various systems. These components facilitate the transfer of electrical power and signals necessary for the operation of critical truck functions, including engine management, lighting, and communication systems. Maintaining these connections is essential for optimal truck performance, as any failure or degradation in the electrical system can lead to operational inefficiencies or safety hazards 2.

Purpose and Role

The Electrical Connector Repair Terminal 3822920 is designed to address the need for efficient and safe repair of electrical connections in trucks. It enables technicians to restore damaged or faulty connectors, ensuring consistent and safe electrical performance across various truck systems. By providing a reliable means to repair electrical connections, this terminal helps maintain the integrity of the truck’s electrical network, supporting its operational efficiency and safety 3.

Key Features

The Electrical Connector Repair Terminal 3822920 is characterized by its robust design and the use of high-quality materials, which enhance its functionality and durability in demanding heavy-duty applications. Its design allows for easy installation and repair, while the materials used ensure it can withstand the harsh conditions typical of truck operations. Unique characteristics of this terminal may include corrosion resistance, high electrical conductivity, and compatibility with a wide range of electrical systems.

Benefits

Utilizing the Electrical Connector Repair Terminal 3822920 offers several benefits, including improved electrical reliability, ease of repair, and potential cost savings over time. By ensuring reliable electrical connections, it helps prevent downtime caused by electrical failures. The ease of repair it provides can reduce maintenance time and labor costs, while its durability contributes to long-term cost savings by minimizing the need for frequent replacements.

Troubleshooting and Maintenance

Common issues with electrical connectors in heavy-duty trucks can include corrosion, wear, and damage from vibration or environmental factors. The Electrical Connector Repair Terminal 3822920 can be used to address these problems by providing a reliable repair solution. Regular maintenance practices, such as inspecting connectors for signs of wear or corrosion and ensuring they are securely connected, can help ensure the longevity and effectiveness of electrical connections.

Installation Process

Installing the Electrical Connector Repair Terminal 3822920 involves several steps to ensure optimal performance and safety. The process may require specific tools and additional components, depending on the application. Proper installation is crucial to ensure the terminal functions as intended, providing a secure and reliable electrical connection. Detailed instructions should be followed to achieve the best results.

Compatibility and Applications

The Electrical Connector Repair Terminal 3822920 is designed for use in a variety of heavy-duty truck applications. It is compatible with different types of trucks and electrical systems, making it a versatile component for fleet maintenance. Its applications extend to various truck components and systems, including engine management, lighting, and communication systems, where reliable electrical connections are paramount.

Safety Considerations

When working with electrical components in heavy-duty trucks, it is important to observe safety considerations to prevent accidents and ensure compliance with safety standards. This includes ensuring the truck’s electrical system is de-energized before beginning any work, using appropriate personal protective equipment, and following manufacturer guidelines for handling, installing, and maintaining electrical components. Proper safety practices are essential to protect both the technician and the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins provides a wide range of components and solutions for the automotive industry, including heavy-duty trucks. Their expertise in engine and component design ensures that products like the Electrical Connector Repair Terminal 3822920 meet the high standards required for reliable and efficient operation in demanding environments.

Cummins Electrical Connector Repair Terminal 3822920 Compatibility

The Cummins Electrical Connector Repair Terminal 3822920 is designed to ensure reliable electrical connections in various engine systems. This repair terminal is a critical component for maintaining the integrity of electrical circuits, particularly in high-stress environments such as those found in industrial and commercial engines.

K50 Series Engines

The K50 series engines, known for their robust performance and durability, benefit significantly from the use of the 3822920 repair terminal. This part is engineered to fit seamlessly into the electrical systems of these engines, providing a secure and stable connection that can withstand the rigors of continuous operation. The terminal’s design ensures that it can handle the specific electrical demands of the K50 engines, contributing to overall system reliability and longevity.

Group Compatibility

The 3822920 repair terminal is also compatible with a broader group of Cummins engines, including but not limited to, the K50 series. This compatibility extends to various engine models where similar electrical connection standards are employed. The terminal’s universal design allows it to be used across different engine types, making it a versatile solution for maintaining electrical integrity in multiple applications.

By integrating the 3822920 repair terminal into the electrical systems of these engines, users can expect enhanced performance and reduced downtime due to electrical faults. This part is a testament to Cummins’ commitment to providing high-quality, reliable components that support the operational efficiency of their engines.

Role of Part 3822920 Electrical Connector Repair Terminal in Engine Systems

The Part 3822920 Electrical Connector Repair Terminal is an essential component in maintaining the integrity and functionality of various engine systems. Its application spans across several key components, ensuring seamless electrical connections and reliable performance.

Integration with Bi-Fuel Systems

In Bi-Fuel Base Inline and Bi-Fuel Base Vee kits, the Electrical Connector Repair Terminal is utilized to repair and maintain the electrical connections between the fuel system components. This ensures that the transition between gasoline and alternative fuel operations is smooth, without any electrical disruptions that could lead to engine misfires or inefficient fuel delivery.

For the Bi-Fuel STC Upfit kit, the terminal plays a similar role but is particularly important in upfitted systems where additional components and wiring are introduced. It helps in securing connections that are vital for the proper functioning of the upfitted fuel system, thereby enhancing the overall reliability of the engine.

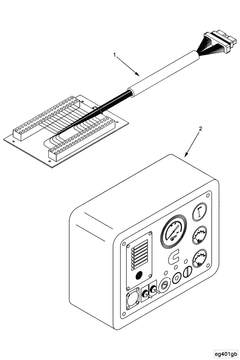

Service Tool Applications

When employed with Service Tools, the Electrical Connector Repair Terminal aids in diagnosing and repairing electrical faults within the engine system. Technicians rely on this component to ensure that all connections are secure and free from corrosion or damage, which is essential for accurate diagnostics and effective repairs.

Wiring Harness Repair Kit

In conjunction with a Wiring Harness Repair Kit, the terminal is indispensable. It allows for the precise repair of damaged wiring harnesses by providing a reliable connection point. This is particularly important in high-stress environments where wiring can be prone to wear and tear, ensuring that the electrical signals are transmitted without interference.

Overall, the Electrical Connector Repair Terminal (Part 3822920) is a versatile component that enhances the durability and performance of engine systems by ensuring robust and reliable electrical connections.

Conclusion

The Electrical Connector Repair Terminal 3822920 by Cummins is a critical component for maintaining the electrical integrity of heavy-duty trucks and engines. Its robust design, compatibility with various systems, and ease of installation make it an invaluable tool for technicians. By ensuring reliable electrical connections, this terminal contributes to the overall performance, safety, and efficiency of the vehicles it serves.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.