3688983

Electrical Connector Boot

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Electrical connector boots are essential components designed to protect electrical connections in various applications, including heavy-duty trucks. The 3688983 Electrical Connector Boot, produced by Cummins, serves this purpose with a focus on durability and reliability. Electrical connectors are vital in heavy-duty trucks, facilitating the transfer of power and signals between different components of the vehicle’s electrical system. Ensuring these connections are well-protected is key to maintaining the truck’s operational efficiency and safety.

Basic Concepts of Electrical Connector Boots

An electrical connector boot is a protective covering designed to encase electrical connections. Its primary function is to shield these connections from environmental factors such as moisture, dust, and physical damage. Within a truck’s electrical system, the boot ensures that the integrity of the electrical connections is maintained, which is crucial for the consistent performance of the vehicle. These boots are commonly manufactured from materials like rubber, silicone, or thermoplastic elastomers, chosen for their flexibility, durability, and resistance to various environmental conditions 1.

Role of the 3688983 Electrical Connector Boot in Truck Operation

The 3688983 Electrical Connector Boot plays a specific role in the operation of a truck by providing a secure and protected environment for electrical connections. This protection helps in maintaining the reliability and efficiency of the truck’s electrical system. By shielding connections from external elements, the boot contributes to the overall stability and performance of the electrical network, ensuring that power and signals are transmitted without interruption 2.

Key Features of the 3688983 Electrical Connector Boot

The 3688983 model is characterized by several key features that enhance its performance and durability. Its design includes a snug fit around the electrical connections, ensuring comprehensive coverage and protection. The material composition of the boot is selected for its superior resistance to environmental factors, including extreme temperatures and chemical exposure. Additionally, the boot may feature unique characteristics such as flame retardancy or enhanced flexibility, further contributing to its effectiveness in protecting electrical connections 3.

Benefits of Using the 3688983 Electrical Connector Boot

Incorporating the 3688983 Electrical Connector Boot into a truck’s electrical system offers several benefits. It provides improved protection against environmental factors, which can otherwise lead to corrosion, short circuits, or complete failure of electrical connections. The enhanced stability of electrical connections contributes to the overall reliability of the truck’s electrical system. Furthermore, by ensuring the longevity and efficiency of these connections, the boot can potentially increase the system’s efficiency and longevity, leading to reduced maintenance costs and improved vehicle performance 4.

Troubleshooting and Maintenance Suggestions

Common issues with electrical connector boots, including the 3688983 model, may involve damage to the boot itself or the connections it protects. Troubleshooting steps include inspecting the boot for signs of wear, cracking, or exposure of the electrical connections. If damage is detected, replacing the boot is recommended to restore protection to the connections. Regular maintenance involves checking the condition of the boot and ensuring it remains securely fitted around the connections. Keeping the area around the connections clean and free from debris can also help in maintaining the integrity of the electrical system.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history rooted in diesel engine technology, Cummins has expanded its expertise to include a wide range of power solutions. The company is committed to innovation, quality, and customer satisfaction, making it a trusted name in the automotive and heavy-duty truck industries. Cummins’ products, including the 3688983 Electrical Connector Boot, are designed with a focus on durability, reliability, and performance, reflecting the company’s dedication to excellence in engineering and manufacturing.

Cummins Engine Part 3688983: Electrical Connector Boot Compatibility

The Cummins part 3688983, an Electrical Connector Boot, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the integrity of electrical connections, ensuring that they remain protected from environmental factors and wear.

ISB6.7 Series

- ISB6.7 CM2350 B101

- QSB6.7 CM2350 B105

ISX Series

- ISX12 CM2350 X102

- ISX15 CM2350 X101

QSK Series

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK50 CM2350 K108

- QSK95 CM2350 K111

QSL and QST Series

- QSL9 CM2350 L102

- QST30 CM2350 T101

QSX Series

- QSX15 CM2350 X105

X Series

- X11 CM2670 X126B

- X12 CM2350 X119B

- X12 CM2670 X121B

- X13 CM2670 X122B

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

Z Series

- Z14 CM2670 Z103B

This Electrical Connector Boot is engineered to provide a secure fit for these engines, ensuring that the electrical connections remain robust and reliable. It is important to verify the compatibility of this part with the specific engine model to ensure proper fitment and functionality.

Role of Part 3688983 Electrical Connector Boot in Engine Systems

The part 3688983 Electrical Connector Boot is an essential component that ensures the integrity and functionality of various wiring systems within engine systems. Its primary role is to provide a protective enclosure for electrical connectors, safeguarding them from environmental factors such as moisture, dust, and physical damage.

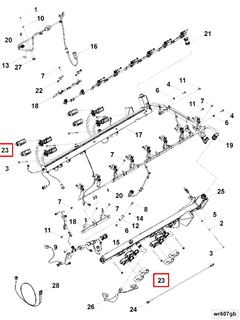

Integration with Electronic Control Module Wiring Harness

When integrated with the Electronic Control Module (ECM) Wiring Harness, the Electrical Connector Boot plays a significant role in maintaining the reliability of the connections. The ECM Wiring Harness is responsible for transmitting signals between the ECM and various sensors and actuators throughout the engine system. The boot ensures that these connections remain secure and unaffected by external contaminants, thereby ensuring consistent signal transmission.

Protection for Harness and Wiring

In conjunction with the Harness and individual Wiring components, the Electrical Connector Boot offers an additional layer of protection. This is particularly important in harsh operating environments where the engine is exposed to extreme temperatures, vibrations, and corrosive agents. The boot helps in prolonging the lifespan of the wiring by preventing wear and tear.

Role in Engine Control Systems

For Engine Control systems, the Electrical Connector Boot is instrumental in maintaining the stability of the electrical connections. Engine Control systems rely on precise and timely data transmission to function correctly. The boot ensures that the connections between the Engine Control Module (ECM) and other components remain intact, facilitating accurate data exchange.

Application in Wiring Harness Kits

Within Wiring Harness Kits, which often include pre-assembled wiring solutions for various engine components, the Electrical Connector Boot is used to enhance the durability of the connections. These kits are designed for ease of installation and the boot contributes to the overall robustness of the wiring setup, making it more resistant to the rigors of engine operation.

Summary of Component Interactions

- ECM Wiring Harness: Ensures secure and contaminant-free connections for signal transmission.

- Harness and Wiring: Provides protection against environmental factors, extending the lifespan of wiring.

- Engine Control Systems: Maintains the integrity of electrical connections for accurate data transmission.

- Wiring Harness Kits: Enhances the durability and reliability of pre-assembled wiring solutions.

Conclusion

The 3688983 Electrical Connector Boot is a critical component in the maintenance and operation of heavy-duty truck electrical systems. By providing robust protection against environmental factors, it ensures the reliability and efficiency of electrical connections, contributing to the overall performance and safety of the vehicle. Regular maintenance and timely replacement of this part are essential to maintain the integrity of the truck’s electrical system.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Reif, K. Ed. (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.