This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

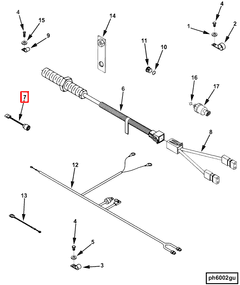

The 3408511 Electrical Cable, manufactured by Cummins, is designed for use in commercial trucks. This part is integral to the electrical system, facilitating the connection and operation of various electrical components. Cummins is recognized for its commitment to quality and innovation in producing reliable automotive components.

Basic Concepts of Electrical Cables

Electrical cables, such as the 3408511, are conductors that transmit electrical power or signals between different components within a vehicle. They are essential for the operation of a truck’s electrical system, enabling the functioning of lights, sensors, communication systems, and other electronic devices. The integrity and quality of these cables are crucial for ensuring the proper operation and safety of the vehicle 1.

Purpose of the 3408511 Electrical Cable

This Cummins part is designed to connect and support specific systems or components within a truck. It plays a role in transmitting electrical signals or power, ensuring that the connected systems operate correctly. This cable is integral to the truck’s electrical network, contributing to the overall functionality and efficiency of the vehicle.

Key Features

The 3408511 Electrical Cable is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the harsh environmental conditions often encountered by commercial trucks. The cable also features resistance to abrasion, corrosion, and extreme temperatures, ensuring long-lasting performance. Additionally, its design specifications are tailored to meet the specific requirements of truck electrical systems, providing a secure and reliable connection 2.

Benefits

Utilizing the 3408511 Electrical Cable offers several advantages. It contributes to improved reliability and performance of the truck’s electrical systems, reducing the likelihood of electrical failures. Moreover, its durable construction can lead to potential cost savings over time by minimizing the need for frequent replacements or repairs.

Installation Considerations

When installing this part, it is important to follow guidelines and best practices to ensure proper fitment and secure connections. This includes verifying that the cable is correctly routed to avoid damage from moving parts or sharp edges and ensuring that all connections are tight and secure to prevent electrical issues.

Troubleshooting Common Issues

Common problems with electrical cables can include loose connections, damage from abrasion or corrosion, and electrical shorts. Troubleshooting the 3408511 involves identifying these issues through visual inspection and electrical testing. Repairing or replacing damaged sections of the cable, as well as ensuring all connections are secure, can resolve many common electrical problems.

Maintenance Tips

Regular maintenance of the 3408511 is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the cable and its connections to remove dirt or corrosion, and replacing the cable if it shows significant signs of deterioration. Adhering to these maintenance practices can help prevent electrical issues and ensure the reliable operation of the truck.

Safety Precautions

Working with electrical cables, including the 3408511, requires observing important safety measures. This includes ensuring the vehicle’s electrical system is de-energized before beginning work to avoid the risk of electrical shock. Additionally, using appropriate personal protective equipment and following safe work practices can help prevent accidents and ensure personal safety.

Cummins: A Brief Overview

Cummins is a renowned manufacturer with a rich history in the automotive industry, particularly in the production of diesel engines and related components. The company is widely recognized for its commitment to quality, innovation, and customer satisfaction. Cummins’ reputation is built on its dedication to producing reliable and high-performance automotive components, including the 3408511 Electrical Cable.

Cummins Electrical Cable Part 3408511 Compatibility

The Cummins Electrical Cable part number 3408511 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical connectivity and performance. This part is engineered to meet the stringent requirements of Cummins engines, providing durability and efficiency in various operational conditions.

QST30 CM552 Engines

The Cummins Electrical Cable part 3408511 is specifically compatible with the QST30 CM552 engines. This compatibility ensures that the electrical systems within these engines function optimally, maintaining the integrity of the power supply and signal transmission. The design of the cable is tailored to fit the unique electrical architecture of the QST30 CM552 engines, facilitating smooth and uninterrupted operation.

Grouping of Compatible Engines

While the primary focus here is on the QST30 CM552 engines, it is important to note that the Cummins Electrical Cable part 3408511 is also compatible with a broader range of Cummins engines. This part is engineered to fit various engine models within the Cummins portfolio, ensuring that it can be used across multiple platforms without compromising on performance or reliability. The versatility of this cable makes it a valuable component for maintaining the electrical systems of different engine types.

Role of Part 3408511 Electrical Cable in Engine Systems

The part 3408511 Electrical Cable is instrumental in ensuring seamless communication and power distribution within engine systems. Specifically, it interfaces with the Engine Control Module (ECM), facilitating the transmission of vital data and electrical signals.

Integration with the Engine Control Module (ECM)

The ECM relies on accurate and timely data to manage engine operations effectively. The 3408511 Electrical Cable connects various sensors and actuators to the ECM, allowing for the monitoring of parameters such as engine temperature, fuel levels, and air intake. This data is essential for the ECM to make real-time adjustments to fuel injection, ignition timing, and other critical functions.

Data Transmission and Signal Integrity

In addition to data transmission, the 3408511 Electrical Cable ensures signal integrity. It is designed to minimize electrical interference and signal loss, which is vital for the accurate interpretation of sensor data by the ECM. This reliability in signal transmission helps maintain engine performance and efficiency.

Power Distribution

Beyond data transmission, the 3408511 Electrical Cable also plays a role in power distribution. It supplies necessary voltage to various components connected to the ECM, ensuring they operate within specified parameters. This consistent power supply is fundamental for the proper functioning of engine subsystems.

Enhanced Diagnostic Capabilities

The Electrical Cable enhances the diagnostic capabilities of the engine system. By providing a robust connection between the ECM and diagnostic tools, it allows for more accurate fault detection and troubleshooting. This facilitates quicker repairs and reduces downtime.

Support for Advanced Engine Features

In modern engine systems, the 3408511 Electrical Cable supports advanced features such as start-stop technology, hybrid systems, and emissions control. It enables the ECM to coordinate these features efficiently, contributing to improved fuel economy and reduced environmental impact.

Conclusion

The 3408511 Electrical Cable is a fundamental component in the engine system, ensuring effective communication, power distribution, and support for advanced engine functionalities. Its integration with the ECM, role in data transmission and signal integrity, and support for advanced engine features make it a critical part of modern engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.