This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

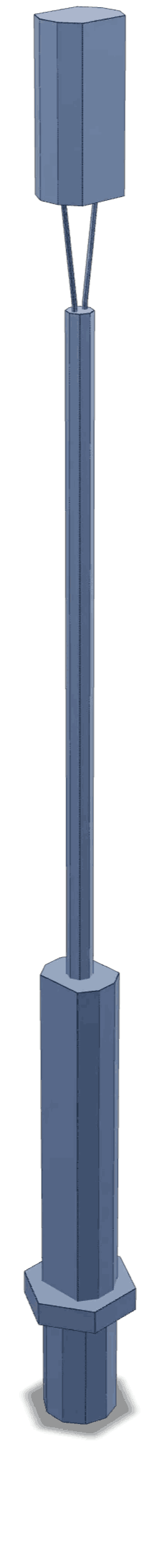

The Cummins 3039525 Magnetic Pickup is a component designed to enhance the functionality of heavy-duty truck engines. Its role is significant in ensuring the smooth operation of the engine management system, contributing to overall vehicle performance and reliability.

Basic Concepts of Magnetic Pickups

A magnetic pickup is a sensor that detects changes in a magnetic field. It operates by generating an electrical signal in response to the movement of a magnetized object, such as a gear or a rotor. This technology is widely used in automotive systems for various applications, including engine management, transmission control, and wheel speed sensing 1.

Purpose of the Cummins 3039525 Magnetic Pickup

This Cummins part serves a specific function within the engine management system of a truck. It is responsible for detecting the position and speed of the engine’s components, such as the crankshaft or camshaft. This information is crucial for the engine control unit (ECU) to make precise adjustments to fuel injection, ignition timing, and other parameters, thereby optimizing engine performance 2.

Key Features

The Cummins 3039525 Magnetic Pickup is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological features that enhance its durability and accuracy. The sensor is engineered to withstand the harsh conditions typical of heavy-duty truck operations, ensuring reliable performance over time 3.

Benefits

The integration of the Cummins 3039525 Magnetic Pickup into a truck’s engine system offers several advantages. It contributes to improved engine performance by providing accurate data to the ECU. This results in more efficient fuel consumption and reduced emissions. Additionally, the sensor enhances the reliability of the engine management system, leading to increased overall vehicle efficiency.

Installation and Integration

Proper installation of the Cummins 3039525 Magnetic Pickup is vital for its effective operation. It should be securely mounted in the engine compartment, with careful attention to alignment and electrical connections. Integration with the engine management system requires precise calibration to ensure that the sensor’s readings are accurately interpreted by the ECU.

Troubleshooting and Maintenance

Regular maintenance of the Cummins 3039525 Magnetic Pickup is recommended to ensure its longevity and optimal performance. This includes checking for secure mounting, inspecting electrical connections, and ensuring the sensor is free from contaminants. Troubleshooting may involve testing the sensor’s output signal and verifying its alignment within the engine system.

Common Issues and Solutions

Frequent problems associated with magnetic pickups can include signal interference, misalignment, or sensor failure. Solutions may involve recalibrating the sensor, adjusting its position, or replacing the sensor if it is found to be faulty. Regular inspections can help identify and address these issues before they lead to significant engine performance issues.

Technological Advancements

The Cummins 3039525 Magnetic Pickup incorporates several technological innovations that enhance its functionality. These include improved signal processing capabilities, enhanced resistance to environmental factors, and integration with advanced engine management systems. These advancements contribute to the sensor’s accuracy, reliability, and overall performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the automotive industry, Cummins has established itself as a reputable provider of heavy-duty truck components. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3039525 Magnetic Pickup in Engine Systems

The magnetic pick-up, identified by part number 3039525, is an integral component within various engine systems, primarily serving to enhance the precision and reliability of ignition timing and fuel injection processes.

Ignition System Integration

In the ignition system, the magnetic pick-up is positioned near the flywheel or crankshaft. As the engine operates, the teeth on the flywheel pass by the magnetic pick-up, generating a series of electrical pulses. These pulses are then sent to the ignition control module, which uses this data to determine the exact position of the crankshaft. This information allows the module to time the spark delivery to the spark plugs with high accuracy, ensuring optimal combustion efficiency and engine performance.

Fuel Injection System Coordination

Within fuel injection systems, the magnetic pick-up plays a similar role by providing the engine control unit (ECU) with real-time data on the crankshaft’s position and speed. This data is essential for the ECU to calculate the precise moment for fuel injection, thereby maintaining the correct air-fuel mixture. The magnetic pick-up’s reliable signal ensures that the fuel injectors operate in sync with the engine’s mechanical movements, leading to improved fuel economy and reduced emissions.

Overall Engine Management

Beyond ignition and fuel systems, the magnetic pick-up contributes to the overall engine management by offering consistent and accurate timing information. This data is utilized by various engine management systems to adjust parameters such as valve timing, turbo boost levels, and other performance-related settings. The result is a more responsive and efficient engine, capable of delivering enhanced power output and smoother operation.

Conclusion

In summary, the Cummins 3039525 Magnetic Pickup is a fundamental component that ensures the synchronization and efficiency of multiple engine systems, playing a key role in the modern automotive engine’s operation. Its integration into engine management systems enhances engine performance, reliability, and efficiency, making it an essential component for heavy-duty truck engines.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.