This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3036577 Pyrometer is a specialized device designed to measure the temperature of exhaust gases in commercial trucks. Its purpose is to provide accurate temperature readings, which are vital for monitoring engine performance and ensuring optimal operation. The significance of this pyrometer lies in its ability to help maintain engine efficiency and longevity by allowing operators to make informed decisions based on precise temperature data 1.

Basic Concepts of Pyrometers

A pyrometer is an instrument used to measure high temperatures. It operates by detecting the thermal radiation emitted by an object and converting it into a temperature reading. Pyrometers are utilized across various industries, including metallurgy, glass manufacturing, and automotive. In the context of commercial trucking, pyrometers play a role in monitoring engine health by providing real-time temperature data of exhaust gases, which can indicate the engine’s operating condition 2.

Purpose of the Cummins 3036577 Pyrometer

The Cummins 3036577 Pyrometer serves a specific function in the operation of a truck by monitoring the temperature of exhaust gases. This monitoring is important for several reasons: it helps in detecting potential issues such as overheating, which can lead to engine damage; it assists in optimizing fuel efficiency by ensuring the engine operates within its ideal temperature range; and it contributes to maintaining emissions standards by providing data that can be used to adjust engine parameters 3.

Key Features

The Cummins 3036577 Pyrometer is characterized by several primary features that enhance its functionality and reliability. These include high accuracy in temperature readings, which ensures precise monitoring of engine conditions. Durability is another key feature, allowing the pyrometer to withstand the harsh environments typical of commercial trucking. Additionally, the pyrometer is designed for easy integration with truck systems, facilitating seamless operation and data collection.

Benefits of Using the Cummins 3036577 Pyrometer

Employing the Cummins 3036577 Pyrometer in truck operations offers several advantages. One of the main benefits is improved engine performance, as operators can use temperature data to make adjustments that enhance efficiency. Additionally, the pyrometer contributes to engine longevity by enabling early detection of issues that could lead to damage. Furthermore, the use of this pyrometer can aid in maintaining compliance with emissions regulations by providing accurate temperature data for engine management systems.

Installation and Integration

Proper installation and integration of the Cummins 3036577 Pyrometer within a truck’s engine system are important for ensuring accurate temperature readings and reliable operation. Installation typically involves mounting the pyrometer in a location that provides a clear view of the exhaust gases, ensuring it is securely fastened and properly aligned. Integration with the truck’s engine management system allows for real-time data collection and analysis, enhancing overall engine performance and maintenance practices.

Troubleshooting and Maintenance

To ensure optimal performance of the Cummins 3036577 Pyrometer, it is important to address common issues promptly and perform routine maintenance. Troubleshooting may involve checking for obstructions in the pyrometer’s line of sight, ensuring proper calibration, and verifying connections to the engine management system. Routine maintenance practices include cleaning the pyrometer’s sensor and inspecting for physical damage. These practices help maintain the accuracy and reliability of temperature readings.

Safety Considerations

When using and maintaining the Cummins 3036577 Pyrometer, it is important to observe safety practices to protect both the equipment and the operator. This includes ensuring the pyrometer is installed in a location that is not exposed to direct contact with hot surfaces or moving parts. Additionally, operators should use appropriate personal protective equipment when performing maintenance or troubleshooting to prevent injuries from high temperatures or sharp edges.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company is known for its commitment to quality, reliability, and customer satisfaction, providing solutions that enhance the performance and efficiency of commercial vehicles.

Cummins Pyrometer 3036577 Compatibility with K19, K38, and K50 Engines

The Cummins Pyrometer 3036577 is designed to measure the temperature of exhaust gases, providing essential data for ensuring the engines operate within safe and efficient parameters.

K19 and K38 Engines

For the K19 and K38 engines, the 3036577 pyrometer is engineered to fit seamlessly into the exhaust system. Its placement is crucial for accurate temperature readings, which are vital for preventing engine overheating and ensuring efficient combustion. The pyrometer’s design allows for easy installation and removal, facilitating routine maintenance checks and minimizing downtime.

K50 Engine

The K50 engine, known for its robust performance and reliability, also benefits from the precise temperature monitoring provided by the 3036577 pyrometer. In this engine, the pyrometer is strategically positioned to capture the exhaust temperature at a critical point, ensuring that the engine’s operational parameters are maintained. This placement is essential for optimizing fuel efficiency and extending the engine’s lifespan.

Grouping Considerations

When considering the K19 and K38 engines together, it is evident that the 3036577 pyrometer is designed with a similar installation approach for both models. This uniformity in design facilitates easier inventory management and maintenance for operators who use both engine types. The K50 engine, while distinct in its specifications, also integrates the pyrometer in a manner that aligns with Cummins’ commitment to precision and reliability.

The pyrometer’s compatibility with these engines underscores Cummins’ focus on providing high-quality, interchangeable components that enhance engine performance and longevity.

Role of Part 3036577 Pyrometer in Engine Systems

The integration of part 3036577 Pyrometer within engine systems is essential for maintaining optimal performance and safety. This component is primarily responsible for measuring the temperature of exhaust gases, providing real-time data that is vital for engine management.

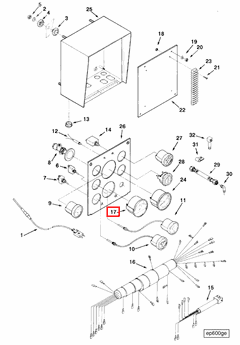

Instrument Panel

The Pyrometer is directly connected to the instrument panel, where it displays the temperature readings. This allows engineers and mechanics to monitor the engine’s thermal conditions continuously. By observing these readings, they can make informed decisions regarding engine load, fuel efficiency, and potential overheating issues. The instrument panel serves as the primary interface for this data, ensuring that all relevant personnel have immediate access to critical temperature information.

Panel Instrument

In addition to the instrument panel, the Pyrometer interacts with various panel instruments that are part of the engine’s diagnostic system. These instruments often include gauges and sensors that work in tandem with the Pyrometer to provide a comprehensive view of the engine’s health. For instance, the temperature data from the Pyrometer can be cross-referenced with other metrics such as oil pressure and coolant temperature, offering a holistic understanding of the engine’s operating conditions. This interplay between the Pyrometer and panel instruments enhances the overall diagnostic capabilities of the engine system, allowing for more precise tuning and maintenance.

Conclusion

The Cummins 3036577 Pyrometer plays a significant role in the maintenance and operation of commercial truck engines by providing accurate temperature readings of exhaust gases. Its integration into engine systems allows for real-time monitoring and data collection, which are crucial for optimizing engine performance, ensuring safety, and maintaining compliance with emissions regulations. Proper installation, routine maintenance, and adherence to safety practices are essential for maximizing the benefits of this pyrometer.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.