This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3035766 Hour Meter is a specialized device designed to monitor and record the operational hours of commercial trucks. This meter plays a role in the maintenance and operational efficiency of trucks by providing accurate data on engine runtime. Understanding its purpose and functionality is vital for fleet managers and truck operators to ensure optimal performance and longevity of their vehicles 1.

Basic Concepts of Hour Meters

An hour meter is a device that measures the total operating time of an engine. It functions by counting the number of hours the engine runs, providing a precise record of usage. This information is crucial for tracking engine runtime, which is a key factor in determining maintenance schedules and predicting when parts may need replacement. Accurate tracking of engine hours helps in scheduling timely maintenance, thereby enhancing the engine’s lifespan and ensuring consistent performance 2.

Purpose of the Cummins 3035766 Hour Meter

The Cummins 3035766 Hour Meter is designed to monitor the operational hours of a truck’s engine. It plays a role in the operation of a truck by providing real-time data on engine runtime, which is essential for maintaining an accurate maintenance schedule. By tracking the number of hours the engine has been in operation, this meter aids in predicting when maintenance or part replacements may be necessary, thus contributing to the overall efficiency and reliability of the truck 3.

Key Features

The Cummins 3035766 Hour Meter boasts several key features that enhance its functionality and integration within a truck’s system. These include high accuracy in recording engine hours, a clear and easy-to-read display, and the capability to integrate with other truck systems for comprehensive monitoring. Its design ensures durability and reliability, making it suitable for the demanding conditions of commercial truck operations.

Benefits of Using the Cummins 3035766 Hour Meter

Utilizing the Cummins 3035766 Hour Meter offers several advantages. It enables improved maintenance scheduling by providing accurate engine runtime data, which helps in planning maintenance activities more effectively. This leads to enhanced engine longevity, as timely maintenance can prevent unexpected breakdowns and extend the life of the engine. Additionally, the meter contributes to increased operational efficiency by ensuring that the truck is maintained according to its actual usage, rather than relying on estimated timelines.

Installation and Setup

Proper installation and setup of the Cummins 3035766 Hour Meter are crucial for its effective operation. The installation process involves connecting the meter to the truck’s engine and ensuring it is securely mounted. Setup includes calibrating the meter to accurately record engine hours and integrating it with the truck’s existing systems for seamless operation. Following the manufacturer’s guidelines during installation and setup ensures the meter functions correctly and provides reliable data.

Troubleshooting Common Issues

Common issues with the Cummins 3035766 Hour Meter may include inaccurate readings or display malfunctions. Troubleshooting these problems involves checking the connections to ensure they are secure and functioning correctly. If the meter displays incorrect readings, recalibrating it according to the manufacturer’s instructions may resolve the issue. For display problems, ensuring the meter is receiving power and is properly connected can help identify and fix the problem.

Maintenance Tips

Regular maintenance of the Cummins 3035766 Hour Meter is important to ensure its continued accurate operation. This includes checking the connections periodically to ensure they remain secure and functioning correctly. Cleaning the meter’s display and housing can prevent dust and debris from affecting its performance. Additionally, keeping the meter’s firmware up to date can ensure it continues to operate efficiently and integrate seamlessly with other truck systems.

Integration with Fleet Management Systems

The Cummins 3035766 Hour Meter can be integrated with fleet management systems to optimize truck performance and maintenance. This integration allows for the automatic collection of engine runtime data, which can be analyzed to predict maintenance needs and optimize fleet operations. By incorporating the hour meter’s data into fleet management systems, operators can make informed decisions about maintenance schedules, part replacements, and overall fleet management, leading to improved efficiency and reduced downtime.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various industries. The company’s extensive product range and dedication to advancing technology make it a trusted partner in the automotive and heavy-duty truck industries.

Cummins Hour Meter Compatibility with Various Engine Models

The Cummins part 3035766, an Hour Meter, is a crucial component for monitoring engine operational hours across a variety of engine models. This part is designed to integrate seamlessly with several Cummins engine series, ensuring accurate tracking of engine run time. Below is a detailed overview of its compatibility with the listed engines:

K-Series Engines

- K19: The K19 engine benefits from the precise monitoring provided by the 3035766 Hour Meter, ensuring operators can maintain and service the engine at optimal intervals.

- K38: Similarly, the K38 engine utilizes this hour meter to track operational hours, aiding in the scheduling of maintenance and reducing downtime.

- K50: The K50 engine also integrates with the 3035766 Hour Meter, providing reliable data for maintenance planning and performance analysis.

M-Series Engines

- M11 CELECT PLUS: The M11 CELECT PLUS engine is equipped with the 3035766 Hour Meter, offering advanced monitoring capabilities that enhance engine management.

- M11 MECHANICAL: The M11 MECHANICAL engine also supports this hour meter, ensuring accurate tracking of engine hours for effective maintenance scheduling.

N-Series Engines

- N14 MECHANICAL: The N14 MECHANICAL engine is compatible with the 3035766 Hour Meter, providing essential data for maintenance and performance monitoring.

QSK-Series Engines

- QSK19 CM500: The QSK19 CM500 engine integrates with the 3035766 Hour Meter, offering precise monitoring of engine hours to support efficient maintenance practices.

V-Series Engines

- V28: The V28 engine utilizes the 3035766 Hour Meter for accurate tracking of operational hours, facilitating timely maintenance and reducing unexpected downtime.

- V903: The V903 engine also supports this hour meter, ensuring reliable data for maintenance planning and performance monitoring.

NH/NT Series Engines

- NH/NT 855: The NH/NT 855 engine is compatible with the 3035766 Hour Meter, providing essential data for maintenance and performance analysis.

The Cummins part 3035766 Hour Meter is engineered to ensure compatibility and reliability across these diverse engine models, making it an indispensable tool for engine management and maintenance.

Role of Part 3035766 Hour Meter in Engine Systems

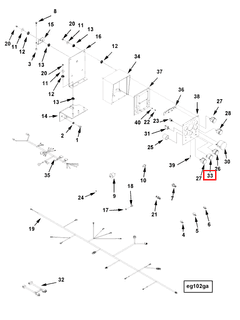

The Part 3035766 Hour Meter is an integral component within various engine systems, providing essential data for maintenance and operational efficiency. It is typically integrated into the Instrument Panel Assembly, which is a comprehensive unit that houses multiple engine instruments and displays.

When installed, the Hour Meter is connected to the Engine Instrument Panel, a specialized panel designed to monitor and display various engine parameters. This panel often includes other instruments such as tachometers, temperature gauges, and fuel level indicators. The Hour Meter’s role is to accurately record the operational hours of the engine, offering valuable data for scheduled maintenance and performance assessments.

In more complex systems, the Hour Meter may be part of the Instrument Assembly Panel, which combines both engine and non-engine related instruments. This setup allows for a centralized monitoring location, enhancing the operator’s ability to quickly assess the engine’s condition and operational status.

The Hour Meter is also frequently found within the Instrument Panel Enclosure, a protective housing that shields the instruments from environmental factors such as dust, moisture, and physical impacts. This enclosure ensures the longevity and reliability of the Hour Meter and other instruments.

Additionally, in systems with an Engine Instrument Enclosure Assembly, the Hour Meter is encased along with other critical engine instruments, providing a robust and integrated solution for engine monitoring. This assembly is particularly important in harsh operating environments where protection and durability are paramount.

Overall, the Part 3035766 Hour Meter plays a significant role in providing accurate operational hour data, which is essential for maintaining engine health and ensuring optimal performance across various engine systems.

Conclusion

The Cummins 3035766 Hour Meter is a vital tool for monitoring and maintaining the operational efficiency of commercial trucks. By providing accurate engine runtime data, it enables fleet managers and operators to schedule timely maintenance, predict part replacements, and enhance overall engine performance. Its integration with various engine models and fleet management systems further underscores its importance in modern truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.