This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Terminal Electric 3021332 is a component manufactured by Cummins, a well-established name in the commercial truck industry. This terminal electric plays a significant role in the electrical systems of commercial trucks, contributing to the efficient operation of these vehicles. Understanding its function and importance can help fleet operators and technicians maintain and optimize truck performance.

Basic Concepts of Terminal Electrics

Terminal electrics are components used in electrical systems to facilitate the transfer of electrical power. They serve as connection points where electrical circuits can be joined or separated. These terminals ensure a secure and reliable connection, which is vital for the consistent operation of electrical systems in vehicles. They help in distributing power to various electrical components and systems within the truck 1.

Role of Terminal Electric 3021332 in Truck Operation

The Terminal Electric 3021332 is designed to play a specific role in the electrical system of a commercial truck. It acts as a connection point for various electrical circuits, allowing for the efficient transfer of power to critical components such as lights, sensors, and other electrical devices. This terminal electric interacts with other components by providing a stable and secure connection, ensuring that electrical power is distributed effectively throughout the truck’s systems.

Key Features

The Terminal Electric 3021332 is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to corrosion and wear, ensuring long-lasting use in demanding environments. The terminal is engineered to provide a robust connection, minimizing the risk of electrical faults. Additionally, it is designed to be easy to install and maintain, which is beneficial for fleet operators and technicians 2.

Benefits of Using Terminal Electric 3021332

Utilizing the Terminal Electric 3021332 offers several advantages. It contributes to improved electrical efficiency by ensuring a secure and reliable connection, which can lead to better overall performance of the truck’s electrical systems. The reliability of this terminal electric reduces the likelihood of electrical issues, which can result in fewer downtimes and lower maintenance costs for fleet operators. Additionally, its durable construction helps in withstanding the rigors of commercial truck operations, providing long-term value 3.

Installation and Integration

Proper installation and integration of the Terminal Electric 3021332 into a truck’s electrical system are important for ensuring optimal performance. Before installation, it is important to ensure that the electrical system is clean and free from any corrosion or damage. The terminal should be securely fastened to prevent any loose connections that could lead to electrical issues. Following the manufacturer’s guidelines for installation will help in achieving a reliable and efficient electrical connection.

Maintenance and Troubleshooting

Routine maintenance of the Terminal Electric 3021332 is important for ensuring its longevity and optimal performance. Regular inspections should be conducted to check for any signs of wear, corrosion, or loose connections. Cleaning the terminal and its surrounding area can help prevent the buildup of dirt and debris that could affect its performance. If any issues are detected, they should be addressed promptly to prevent further complications. Troubleshooting tips include checking for proper connections, ensuring the terminal is securely fastened, and verifying that there are no signs of damage or corrosion.

Common Issues and Solutions

Frequent problems associated with terminal electrics can include loose connections, corrosion, and wear. These issues can often be addressed by ensuring that the terminal is properly installed and maintained. Regular cleaning and inspection can help prevent corrosion and detect any signs of wear early. If a loose connection is detected, it should be tightened or repaired as necessary. In cases of significant corrosion or damage, the terminal may need to be replaced to ensure reliable electrical performance.

Manufacturer - Cummins

Cummins is a reputable manufacturer with a long-standing history in the commercial truck industry. Known for its commitment to quality and innovation, Cummins has established itself as a leader in producing reliable and high-performance components for commercial vehicles. The company’s dedication to excellence is reflected in its products, including the Terminal Electric 3021332, which is designed to meet the demanding requirements of commercial truck operations.

Cummins Terminal Electric 3021332 Compatibility with Engine Models

The Cummins Terminal Electric part number 3021332 is designed to integrate seamlessly with a variety of engine models, ensuring reliable electrical performance across different applications. This terminal electric is compatible with the following engines:

K-Series Engines

- K19

- K38

- K50

The K-Series engines, including the K19, K38, and K50, are known for their robust design and efficiency. The 3021332 terminal electric is engineered to fit these engines, providing a stable electrical connection that is crucial for the engine’s operation.

N-Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine is a high-performance engine that benefits from the precise electrical connections provided by the 3021332 terminal electric. This part ensures that the engine’s electrical systems function optimally, contributing to the overall reliability and performance of the engine.

V-Series Engines

- V28

The V28 engine is another model that is compatible with the 3021332 terminal electric. This compatibility ensures that the electrical systems within the V28 engine are properly connected, supporting the engine’s functionality and efficiency.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is designed for heavy-duty applications and requires reliable electrical connections to maintain performance. The 3021332 terminal electric is specifically designed to fit this engine, ensuring that the electrical systems operate without issues.

By ensuring compatibility with these diverse engine models, the Cummins Terminal Electric 3021332 provides a versatile solution for maintaining the electrical integrity of various engine types.

Role of Terminal Electric Part 3021332 in Engine Systems

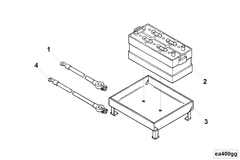

The Terminal Electric part 3021332 is an essential component in the electrical system of various engine setups. It facilitates the secure connection between the battery and the battery cable, ensuring a reliable flow of electrical current. This connection is fundamental for the operation of the Electric Battery Management (EBM) system, which monitors and manages the battery’s performance and health.

In the context of the Electric Starting system, the Terminal Electric part 3021332 plays a significant role. It ensures that the starting motor receives the necessary electrical power from the battery to initiate engine start-up. This component is integral to maintaining the integrity of the electrical connections, which is vital for the consistent and efficient operation of the engine’s electrical systems.

Conclusion

The Terminal Electric 3021332 by Cummins is a critical component in the electrical systems of commercial trucks. Its robust design, compatibility with various engine models, and key features make it an essential part for ensuring reliable and efficient electrical performance. Proper installation, maintenance, and troubleshooting are vital for maximizing the benefits of this terminal electric, contributing to the overall performance and longevity of commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.