This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

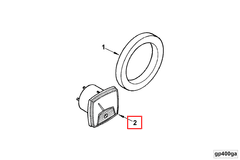

The Cummins 3015037 Ammeter is a specialized component designed for use in commercial trucks. It serves to monitor and indicate the flow of electrical current within the vehicle’s electrical system. This Cummins part plays a role in ensuring the electrical system operates efficiently and reliably, contributing to the overall performance and safety of the truck 1.

Basic Concepts of an Ammeter

An ammeter is an instrument used to measure the current flowing through a circuit. It operates by allowing a portion of the current to pass through a coil, which interacts with a magnetic field to produce a deflection on a pointer or digital display. This measurement is crucial for diagnosing electrical issues and ensuring that components receive the correct amount of current for optimal operation 2.

Purpose of the Cummins 3015037 Ammeter

The Cummins 3015037 Ammeter is specifically designed to monitor and indicate the current flow in the electrical system of a truck. By providing real-time data on current levels, it helps in identifying potential issues such as overloading or short circuits. This monitoring capability is vital for maintaining the health of the electrical system and ensuring that all components function correctly 3.

Key Features

The Cummins 3015037 Ammeter is characterized by its robust design and high build quality. It features a durable housing that protects the internal components from environmental factors. Additionally, it offers precise current measurement, with clear and easy-to-read indications. The ammeter is also designed for straightforward installation and integration into the truck’s electrical system 4.

Benefits of Using the Cummins 3015037 Ammeter

Incorporating the Cummins 3015037 Ammeter into a truck’s electrical system offers several advantages. It provides enhanced monitoring capabilities, allowing for early detection of electrical issues. This proactive approach can prevent more significant problems and reduce downtime. Furthermore, the ammeter’s reliable performance ensures accurate current readings, contributing to the overall efficiency and safety of the truck 1.

Installation and Integration

To install the Cummins 3015037 Ammeter, it is important to follow the manufacturer’s guidelines to ensure optimal performance and safety. The installation process involves connecting the ammeter into the electrical circuit at the appropriate points. Proper wiring and secure mounting are essential to prevent any issues with the readings or the electrical system. Ensuring that all connections are tight and correctly aligned will help maintain the accuracy and reliability of the ammeter 2.

Troubleshooting and Maintenance

Regular maintenance of the Cummins 3015037 Ammeter is important to ensure its longevity and accurate readings. This includes checking the connections for any signs of corrosion or wear, ensuring the housing is intact, and verifying that the readings are consistent with expected values. If the ammeter displays erratic readings or fails to function, it may indicate a problem with the electrical system that requires further investigation 3.

Common Issues and Solutions

Frequent problems with the Cummins 3015037 Ammeter may include inaccurate readings, failure to display any reading, or physical damage to the unit. Inaccurate readings can often be resolved by checking the connections and ensuring they are secure. If the ammeter fails to display any reading, it may be necessary to inspect the electrical circuit for issues such as blown fuses or faulty components. Physical damage to the ammeter should be addressed by replacing the unit to ensure accurate current measurement 4.

Role in Fleet Management

The Cummins 3015037 Ammeter plays a role in fleet management by providing accurate electrical current readings. This data aids in the diagnosis of electrical issues, allowing for timely maintenance and repairs. By ensuring the electrical system is functioning correctly, the ammeter contributes to the overall health and efficiency of the fleet, helping to minimize downtime and maintain operational standards 1.

About Cummins

Cummins Inc. is a well-established company with a strong reputation in the automotive industry. Founded in 1919, Cummins has a long history of producing high-quality components for engines and power generation systems. The company is known for its commitment to innovation, reliability, and customer satisfaction, making it a trusted name in the industry 2.

Cummins Engine Part 3015037: Ammeter Compatibility

The Cummins part number 3015037, which is an Ammeter, is designed to be compatible with a range of Cummins engines. This part is integral for monitoring the electrical output and ensuring the health of the engine’s electrical system. Below is a detailed look at the compatibility of this ammeter with various Cummins engines:

K19

The K19 engine is a robust and reliable power unit, often used in heavy-duty applications. The ammeter part 3015037 is engineered to fit seamlessly into the K19 engine, providing accurate readings of the electrical current. This ensures that the engine’s electrical system is functioning optimally, which is crucial for maintaining performance and preventing potential failures 3.

N14 MECHANICAL

The N14 MECHANICAL engine is known for its durability and efficiency, making it a popular choice for various industrial applications. The ammeter part 3015037 is specifically designed to integrate with the N14 MECHANICAL engine, offering precise measurements of the electrical current. This compatibility is essential for monitoring the engine’s electrical health and ensuring that it operates within the specified parameters 4.

NH/NT 855

The NH/NT 855 engines are part of Cummins’ lineup of high-performance engines, often used in agricultural and construction equipment. The ammeter part 3015037 is compatible with these engines, providing reliable and accurate readings of the electrical current. This ensures that the engine’s electrical system is functioning correctly, which is vital for maintaining the engine’s performance and longevity 1.

V28

The V28 engine is another high-performance engine from Cummins, known for its power and efficiency. The ammeter part 3015037 is designed to fit the V28 engine, offering precise monitoring of the electrical current. This compatibility is crucial for ensuring that the engine’s electrical system is operating optimally, which is essential for maintaining the engine’s performance and reliability 2.

By ensuring that the ammeter part 3015037 is compatible with these engines, Cummins provides a reliable and efficient way to monitor the electrical health of their engines. This compatibility is essential for maintaining the performance and longevity of the engines, ensuring that they operate within the specified parameters and preventing potential failures 3.

Role of Part 3015037 Ammeter in Engine Systems

The part 3015037 Ammeter is an essential component in monitoring the electrical current flowing through various engine systems. It provides real-time feedback on the amperage, allowing for precise adjustments and diagnostics.

Integration with Engine Systems

-

Battery Management System (BMS): The Ammeter is connected inline with the battery to measure the current drawn or supplied. This helps in assessing the battery’s state of charge and identifying any anomalies in the electrical load 4.

-

Alternator Circuit: Placed in the circuit between the alternator and the battery, the Ammeter measures the current output from the alternator. This ensures that the alternator is functioning correctly and providing the necessary charge to the battery 1.

-

Starter Motor Circuit: During engine start-up, the Ammeter measures the high current draw from the battery to the starter motor. This data is vital for diagnosing issues related to starter motor efficiency and battery capacity 2.

-

Electrical Load Distribution: The Ammeter is used to monitor the current distribution across various electrical components such as lights, ignition systems, and auxiliary devices. This helps in balancing the load and preventing overloading of the electrical system 3.

-

Diagnostic Systems: Modern engine control units (ECUs) utilize data from the Ammeter to perform diagnostics on the electrical system. Any irregularities in current flow can trigger alerts or corrective actions within the ECU 4.

-

Fuel Injection Systems: In engines with electronic fuel injection, the Ammeter can be used to monitor the current draw of the fuel injectors. This ensures that the injectors are operating within their specified parameters, contributing to optimal fuel delivery and engine performance 1.

-

Heating and Cooling Systems: The Ammeter measures the current consumed by the engine’s heating and cooling systems, including the radiator fan and heater elements. This aids in maintaining the engine’s operating temperature within the desired range 2.

By providing accurate and timely current measurements, the part 3015037 Ammeter plays a significant role in the efficient and reliable operation of various engine systems 3.

Conclusion

The Cummins 3015037 Ammeter is a vital component for monitoring and maintaining the electrical systems in commercial trucks and various Cummins engines. Its robust design, precise measurements, and compatibility with multiple engine models make it an invaluable tool for ensuring the efficient and reliable operation of these systems. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, contributing to the overall performance and safety of the vehicles it serves 4.

-

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ ↩ ↩ ↩ ↩ ↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ ↩ ↩ ↩ ↩ ↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ ↩ ↩ ↩ ↩ ↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.