This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 2892043 Electronic Control Module (ECM) Wiring Assembly is a vital component in the operation of commercial trucks, manufactured by Cummins. This assembly is designed to facilitate the communication between the ECM and various sensors and components within the truck. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing reliable and efficient automotive components 1.

Basic Concepts of Electronic Control Module Wiring Assembly

An Electronic Control Module (ECM) serves as the brain of a truck’s electronic system, managing and regulating various functions to ensure optimal performance. The ECM Wiring Assembly plays a role in connecting the ECM to different sensors and components throughout the truck. This connection allows for the transmission of data and signals, enabling the ECM to monitor and control the truck’s operations effectively 2.

Purpose of the 2892043 Electronic Control Module Wiring Assembly

The 2892043 ECM Wiring Assembly is integral to the truck’s operation by facilitating seamless communication between the ECM and other truck systems. It ensures that the ECM receives accurate data from sensors and can send appropriate signals to components, thereby maintaining the truck’s performance and efficiency. This assembly helps in the coordination of various systems, contributing to the overall functionality of the vehicle 3.

Key Features

The 2892043 ECM Wiring Assembly boasts several key features that enhance its performance and durability. These include a robust design that withstands the harsh conditions of commercial truck environments, high-quality materials that ensure longevity, and unique attributes such as corrosion-resistant coatings and secure connection points. These features contribute to the assembly’s reliability and efficiency in facilitating communication within the truck’s electronic system.

Benefits

The 2892043 ECM Wiring Assembly offers several benefits, including improved reliability in data transmission, enhanced performance of the truck’s electronic systems, and easier diagnostics due to its structured design. These advantages contribute to the overall efficiency and longevity of the truck, making it a valuable component for commercial truck operators.

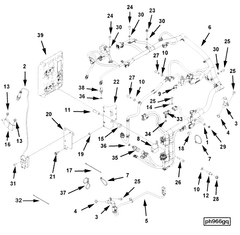

Installation Process

Installing the 2892043 ECM Wiring Assembly involves a series of steps to ensure proper setup. This process includes identifying the correct location for the assembly, connecting it to the ECM and other components, and securing all connections. Tools required may include wire cutters, crimping tools, and a multimeter for testing connections. It is important to follow the manufacturer’s guidelines to ensure the assembly is installed correctly and functions as intended.

Troubleshooting Common Issues

Common issues with the 2892043 ECM Wiring Assembly may include loose connections, damaged wires, or faulty sensors. Troubleshooting these problems involves inspecting the assembly for any visible damage, testing the connections for continuity, and checking the sensors for proper operation. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s electronic system.

Maintenance Tips

To ensure the longevity and optimal performance of the 2892043 ECM Wiring Assembly, regular maintenance is recommended. This includes inspecting the assembly for signs of wear or damage, cleaning the connections to prevent corrosion, and checking for any loose or disconnected wires. Regular maintenance helps in identifying potential issues before they become significant problems, contributing to the overall reliability of the truck.

Role in Diagnostic Systems

The 2892043 ECM Wiring Assembly plays a role in diagnostic systems by facilitating the transmission of data between the ECM and various sensors. This allows for easier identification and resolution of issues within the truck’s electronic systems. The structured design of the assembly aids in pinpointing the source of problems, making diagnostics more efficient and effective.

Integration with Other Systems

The 2892043 ECM Wiring Assembly integrates with other truck systems, such as the engine, transmission, and braking systems, to provide a cohesive operation. This integration allows for the seamless communication and coordination of these systems, contributing to the overall performance and efficiency of the truck. The assembly acts as a vital link, ensuring that all systems work together harmoniously.

About Cummins

Cummins is a renowned manufacturer in the automotive industry, with a rich history of producing high-quality and innovative automotive components. The company is committed to excellence in manufacturing, ensuring that its products meet the highest standards of quality and performance. Cummins’ reputation for reliability and innovation makes it a trusted name in the industry, providing commercial truck operators with confidence in their vehicle’s components.

Electronic Control Module Wiring Assembly (Part 2892043) in Cummins Engines

The Electronic Control Module Wiring Assembly, identified by part number 2892043, is a critical component in the Cummins ISX12 and ISX11.9 CM2250 engines. This wiring assembly is integral to the proper functioning of the engine’s electronic control module (ECM), ensuring seamless communication between the ECM and various engine sensors and actuators.

In the ISX12 and ISX11.9 CM2250 engines, the ECM plays a pivotal role in managing engine performance, emissions control, and diagnostics. The wiring assembly facilitates the transmission of electrical signals, which are essential for the ECM to monitor and adjust engine parameters in real-time. This includes data from sensors such as the manifold absolute pressure sensor, intake air temperature sensor, and exhaust gas recirculation (EGR) valve, among others.

The assembly is designed to withstand the harsh conditions within the engine compartment, including high temperatures and vibrations. Its robust construction ensures reliable performance over the engine’s operational life. Proper installation and maintenance of this wiring assembly are crucial for maintaining optimal engine efficiency and longevity.

For technicians and fleet managers, understanding the role of the Electronic Control Module Wiring Assembly in the ISX12 and ISX11.9 CM2250 engines is essential for diagnosing and resolving issues related to engine performance and emissions. Ensuring that this wiring assembly is in good condition can prevent potential downtime and costly repairs.

Role of Part 2892043 Electronic Control Module Wiring Assembly in Engine Systems

The Electronic Control Module (ECM) Wiring Assembly, identified as part 2892043, is integral to the operation of modern engine systems. This component facilitates the communication between the Engine Control Module (ECM) and various sensors and actuators throughout the engine system.

Integration with the ECM Wiring Harness

The ECM Wiring Assembly is designed to interface seamlessly with the ECM Wiring Harness. This harness is a network of wires that connects the ECM to different parts of the engine, such as the fuel injectors, ignition coils, and various sensors like the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor. The ECM Wiring Assembly ensures that these connections are secure and efficient, allowing for precise control over engine operations.

Communication with the Engine Control Module

The ECM, often referred to as the brain of the engine, relies on the ECM Wiring Assembly to receive data from sensors and send commands to actuators. This bidirectional flow of information is essential for the ECM to make real-time adjustments to engine parameters such as fuel delivery, ignition timing, and emissions control. The ECM Wiring Assembly plays a key role in maintaining the integrity of this data transmission, ensuring that the ECM can optimize engine performance and efficiency.

Enhancing Engine Performance and Efficiency

By providing a reliable connection between the ECM and the engine’s components, the ECM Wiring Assembly contributes to enhanced engine performance and efficiency. It allows the ECM to monitor and adjust engine operations dynamically, leading to improved fuel economy, reduced emissions, and overall better engine responsiveness.

Supporting Diagnostic and Maintenance Functions

The ECM Wiring Assembly also supports diagnostic and maintenance functions. It enables the ECM to communicate with onboard diagnostic systems, facilitating the identification of issues and the retrieval of error codes. This capability is invaluable for mechanics during troubleshooting and maintenance procedures, allowing for more efficient and accurate repairs.

Conclusion

In summary, the ECM Wiring Assembly is a fundamental component in the engine system, ensuring seamless communication between the ECM and various engine components. Its role in maintaining engine performance, efficiency, and diagnostic capabilities underscores its importance in modern engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.