This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

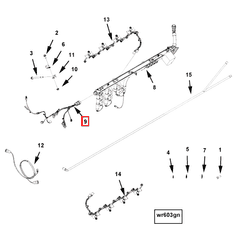

The Electronic Control Module Wiring Harness (Part #2881187) by Cummins is a vital component in the operation of heavy-duty trucks. This wiring harness is designed to facilitate communication between the Electronic Control Module (ECM) and various other systems within the truck. Manufactured by Cummins, a well-established name in the automotive industry, this wiring harness is engineered to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts

The Electronic Control Module (ECM) serves as the brain of the truck, managing and regulating various operations to ensure optimal performance. It processes data from sensors and other input devices to control engine functions, transmission operations, and other critical systems. The wiring harness plays a role in this system by providing the necessary electrical connections between the ECM and the components it controls. It ensures that signals and power are transmitted efficiently and reliably throughout the truck 2.

Purpose of the 2881187 Electronic Control Module Wiring Harness

The 2881187 Wiring Harness is integral to the operation of a truck. It enables the ECM to communicate with and control various truck systems, including the engine, transmission, and emissions systems. By providing a structured pathway for electrical signals, the wiring harness ensures that all components operate in harmony, contributing to the overall efficiency and performance of the truck.

Key Features

The 2881187 Wiring Harness is characterized by several key features that enhance its functionality and durability. Its design incorporates high-quality materials that are resistant to the harsh conditions typically encountered in heavy-duty truck applications. The harness is engineered to withstand vibrations, extreme temperatures, and exposure to chemicals, ensuring long-lasting performance. Additionally, it features robust connectors and terminals that provide secure and reliable connections, minimizing the risk of electrical faults 3.

Benefits

Utilizing the 2881187 Wiring Harness offers several advantages. It contributes to improved reliability by ensuring stable and consistent electrical connections. This leads to enhanced performance of the truck, as the ECM can accurately control and monitor various systems. Furthermore, the design of the harness facilitates easier maintenance, allowing for quick diagnosis and repair of any issues that may arise.

Installation Process

Installing the 2881187 Wiring Harness involves several steps to ensure proper integration with the truck’s systems. Preparatory steps include disconnecting the battery to prevent electrical shocks and ensuring the truck is on a stable surface. The necessary tools for installation may include wire cutters, crimping tools, and a multimeter for testing connections. Safety precautions, such as wearing insulated gloves and using appropriate eye protection, should be observed throughout the process.

Troubleshooting and Maintenance

Common issues with the 2881187 Wiring Harness may include loose connections, damaged wires, or faulty connectors. Troubleshooting involves inspecting the harness for any visible signs of damage and using a multimeter to test the continuity of the connections. Regular maintenance, such as cleaning the connectors and inspecting the harness for wear and tear, can help ensure its longevity and optimal performance.

Safety Considerations

When working with the 2881187 Wiring Harness, it is important to follow electrical safety practices. This includes disconnecting the battery before beginning any work to avoid the risk of electrical shock. Additionally, precautions should be taken to avoid damaging the harness, such as securing it away from moving parts and sharp edges. Using the appropriate tools and following the manufacturer’s guidelines can help prevent accidents and ensure the safety of the technician.

Cummins Overview

Cummins has a long-standing reputation in the automotive industry for its commitment to quality and innovation. Founded in 1919, the company has grown to become a global leader in the manufacturing of diesel engines and related technologies. Cummins is known for its dedication to producing reliable and efficient components that meet the needs of heavy-duty applications. Its products, including the 2881187 Wiring Harness, are designed with the aim of enhancing the performance and durability of trucks.

Conclusion

The Electronic Control Module Wiring Harness part 2881187 is a critical component for the efficient and reliable operation of heavy-duty trucks. Its role in facilitating communication between the ECM and various truck systems, along with its robust design and features, makes it an essential part of modern engine management systems. Proper installation, maintenance, and safety practices are crucial to ensure the longevity and performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.