FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Connector Elbow 5309553, manufactured by Cummins, is a component used in commercial truck systems. Cummins is a well-established name in the automotive industry, known for its quality and innovation in diesel engines and related technologies. This part is significant in ensuring the efficient operation of fluid systems within trucks.

Basic Concepts and Functionality

A Tube Connector Elbow is a fitting used in fluid systems to change the direction of fluid flow. It is commonly employed in various applications where a change in direction is necessary without compromising the integrity of the fluid system. In a truck’s system, the Tube Connector Elbow facilitates the smooth transition of fluids, such as coolant or fuel, through the engine and other components 1.

Purpose of the 5309553 Tube Connector Elbow

This Cummins part plays a role in the operation of a truck by directing the flow of fluids within the system. It ensures that fluids move efficiently from one component to another, maintaining the system’s overall performance. This part is integral to the fluid dynamics within the truck, contributing to the engine’s cooling and lubrication systems 2.

Key Features

The 5309553 is characterized by several key features. It is made from durable materials that can withstand the pressures and temperatures typical in truck fluid systems. The design of the elbow allows for a smooth change in direction of fluid flow, minimizing turbulence and potential leaks. Additionally, it may feature specific threading or connection types to ensure a secure fit within the system 3.

Benefits

Using the 5309553 offers several advantages. Its durable construction ensures longevity, even under demanding conditions. The design contributes to efficient fluid transfer, which is vital for the proper functioning of the truck’s engine and other systems. Furthermore, the part is designed for ease of installation, allowing for straightforward integration into the truck’s fluid system.

Installation and Usage

Proper installation of this part is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure a secure and leak-free connection. Users should follow any specific requirements or recommendations provided by Cummins to maintain the integrity of the fluid system.

Troubleshooting and Maintenance

Common issues with the 5309553 may include leaks or blockages. Regular inspection and maintenance can help identify and address these problems early. Ensuring that connections are tight and free from corrosion can contribute to the longevity and optimal performance of the part.

Compatibility and Applications

The 5309553 is designed for use in various truck systems, particularly those requiring a change in fluid flow direction. It is compatible with specific truck models and fluid systems, ensuring seamless integration and operation.

Safety Considerations

When working with the 5309553, it is important to observe safety guidelines. This includes ensuring that the system is depressurized before making any changes or repairs. Users should also wear appropriate personal protective equipment to safeguard against any potential hazards.

Cummins Overview

Cummins Inc. has a long-standing reputation in the automotive industry, particularly for its diesel engines and related technologies. The company is committed to quality, innovation, and providing reliable solutions for its customers. Cummins’ expertise and dedication to excellence are reflected in its products, including the 5309553 Tube Connector Elbow.

Role of Part 5309553 Tube Connector Elbow in Engine Systems

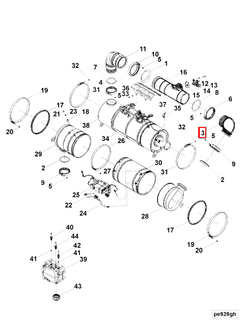

This part is an essential component in the integration and functionality of various engine systems, particularly within the aftertreatment system. This component facilitates the connection between different tubes and hoses, ensuring a secure and efficient transfer of fluids and gases.

In the aftertreatment system, the Tube Connector Elbow is utilized to link the exhaust gas recirculation (EGR) cooler to the intake manifold. This connection is vital for the proper circulation of cooled exhaust gases, which helps in reducing nitrogen oxides (NOx) emissions. The elbow design allows for a smooth transition and minimizes pressure loss, enhancing the overall efficiency of the EGR system.

Additionally, the Tube Connector Elbow plays a significant role in the diesel oxidation catalyst (DOC) and diesel particulate filter (DPF) systems. It connects the exhaust pipe to these aftertreatment devices, ensuring that exhaust gases pass through the catalysts and filters effectively. This connection is important for the reduction of harmful emissions and compliance with environmental regulations.

Furthermore, in the selective catalytic reduction (SCR) system, the Tube Connector Elbow is used to connect the urea injection system to the exhaust stream. This ensures that the urea solution is properly introduced into the exhaust gases, facilitating the conversion of NOx into harmless nitrogen and water vapor.

Conclusion

Overall, the 5309553 Tube Connector Elbow is a key component in maintaining the integrity and performance of the aftertreatment system, contributing to efficient emission control and enhanced engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.