3331872

Male Union Elbow

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

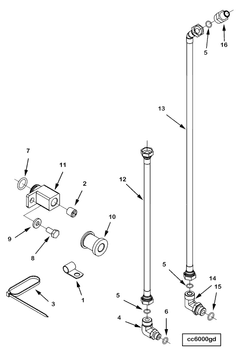

The Male Union Elbow 3331872 is a specialized component manufactured by Cummins, a leader in the automotive and heavy-duty truck industry. This part is designed for use in commercial trucks, where it serves a specific function within the vehicle’s fluid transfer systems. Cummins is known for its commitment to quality and innovation, ensuring that their components meet the rigorous demands of commercial applications.

Basic Concepts and Functionality

A Male Union Elbow is a fitting used in fluid systems to connect two pipes at an angle. The 3331872 operates by providing a secure and leak-proof connection between pipes, allowing for the efficient transfer of fluids. In heavy-duty trucks, this component is often used in hydraulic, fuel, and coolant systems, where precise fluid management is crucial for optimal vehicle performance 1.

Role in Truck Operation

The 3331872 plays a significant role in the operation of a truck by facilitating the transfer of fluids within the system. Its angled design allows for flexible routing of pipes, which is particularly important in the confined spaces typical of truck engine compartments. By ensuring a reliable connection, this component helps maintain the integrity of the fluid transfer system, contributing to the overall efficiency and reliability of the truck 2.

Key Features

The 3331872 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The connection type is designed for easy assembly and disassembly, which simplifies installation and maintenance. Additionally, the design specifications of this component ensure a secure fit, minimizing the risk of leaks and ensuring consistent fluid flow 3.

Benefits

The advantages of using the 3331872 include improved fluid flow due to its precise engineering, which reduces resistance and enhances system efficiency. The ease of installation is another benefit, as the design allows for quick and straightforward connection without the need for specialized tools. Furthermore, the component’s durability and resistance to wear contribute to reduced maintenance requirements, making it a cost-effective choice for commercial truck applications 4.

Installation Considerations

When installing the 3331872, it is important to follow guidelines and best practices to ensure a secure and efficient connection. Necessary tools include wrenches for tightening the fitting and possibly a pipe cutter for precise pipe length. Preparation steps involve cleaning the pipe ends to remove any debris or oxidation that could interfere with the seal. Alignment procedures should ensure that the pipes are correctly positioned before tightening the fitting to prevent stress on the connection 5.

Troubleshooting Common Issues

Common problems associated with the 3331872 may include leaks or blockages. To address leaks, it is important to check the tightness of the fitting and ensure that there is no damage to the pipe or the fitting itself. Blockages can often be resolved by inspecting the fitting for any obstructions and cleaning or replacing the component if necessary. Regular inspection and maintenance can help prevent these issues 6.

Maintenance Tips

To ensure the longevity and optimal performance of the 3331872, regular maintenance is recommended. Inspection intervals should be established based on the truck’s usage and operating conditions, with particular attention paid to signs of wear or corrosion. Cleaning procedures may involve using a compatible solvent to remove any buildup within the fitting, ensuring that fluid flow remains unobstructed 7.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the industry for producing high-quality automotive components. Founded in 1919, Cummins has a long history of innovation and commitment to excellence. Their products are designed to meet the demanding requirements of commercial applications, ensuring reliability and performance. Cummins’ dedication to quality is evident in their rigorous testing and quality control processes, which help maintain their reputation as a trusted provider of automotive components 8.

Cummins Male Union Elbow 3331872 Compatibility

The Cummins Male Union Elbow part number 3331872 is a versatile component designed to fit seamlessly within a variety of Cummins engine models. This part is engineered to provide a secure connection between different sections of the engine’s piping system, ensuring optimal performance and durability.

ISM Series

- ISM CM570/870: The Male Union Elbow is compatible with the ISM CM570/870 engines, facilitating a robust connection in the engine’s piping system.

ISV Series

- ISV (Nissan): This part fits the ISV engines, providing a reliable connection in the engine’s piping system.

ISX Series

- ISX CM870, ISX CM871, ISX12 CM2350 X102, ISX12 G CM2180 EJ, ISX12/ISX11.9 CM2250, ISX15 CM2250, ISX15 CM2250 SN, ISX15 CM2350 X101: The Male Union Elbow is designed to fit these ISX engines, ensuring a secure and efficient connection in the engine’s piping system.

ISZ Series

- ISZ13 CM2150 Z105: This part is compatible with the ISZ13 CM2150 Z105 engine, providing a reliable connection in the engine’s piping system.

KTA Series

- KTA38GC CM558: The Male Union Elbow fits the KTA38GC CM558 engine, ensuring a secure connection in the engine’s piping system.

QSK Series

- QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM850 MCRS, QSK38 CM2150 MCRS, QSK45 CM500, QSK50 CM2150 MCRS, QSK50 CM2350 K108, QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G: The Male Union Elbow is compatible with the QSK19, QSK38, QSK45, QSK50, and QSK60 series engines, providing a secure connection in the engine’s piping system.

QSG Series

- QSG12/X12 CM2350 G110: This part fits the QSG12/X12 CM2350 G110 engine, ensuring a reliable connection in the engine’s piping system.

Role of Part 3331872 Male Union Elbow in Various Engine Systems

The 3331872 Male Union Elbow is a critical component in numerous engine systems, facilitating the connection and redirection of fluid or gas flow. Its applications span across various critical systems, ensuring efficient operation and maintenance.

Air Compressor and Upfit Kit

In an air compressor setup, the Male Union Elbow is utilized to connect the compressor to the air compressor upfit kit. This connection is vital for the distribution of compressed air throughout the system, enabling the operation of pneumatic tools and other air-dependent components.

Crankcase Ventilation

The Male Union Elbow plays a significant role in the crankcase breather system. It connects the breather to the crankcase, allowing for the release of pressure and contaminants from the crankcase. This helps maintain optimal engine performance and longevity by preventing the buildup of harmful gases and moisture.

Filtration Systems

In filtration applications, such as the oil filter cooler or lube oil filter head, the Male Union Elbow ensures a secure connection between the filter and the plumbing. This is essential for the efficient filtration of lubricating oil, which is paramount for reducing wear and tear on engine components.

Fuel Systems

Within the fuel system, the Male Union Elbow is used to connect the fuel control module to the fuel pump and other components. This ensures a consistent and reliable fuel supply to the engine, which is necessary for stable combustion and performance.

Cooling Systems

For compressor coolant and turbocharger coolant systems, the Male Union Elbow facilitates the connection between the plumbing and the respective components. This is important for dissipating heat and maintaining optimal operating temperatures, which is essential for the durability and efficiency of these systems.

Turbocharger Systems

In turbocharger applications, the Male Union Elbow is used to connect various components such as the turbocharger bearing housing, turbocharger gasket kit, and turbocharger housing repair kit. This ensures that the turbocharger receives the necessary lubrication and cooling, which is vital for its performance and longevity.

Auxiliary Systems

The Male Union Elbow is also integral in auxiliary cooling systems, where it connects the plumbing to the turbocharger and other heat-generating components. This helps in managing the thermal load and ensuring that the engine operates within safe temperature ranges.

Corrosion Resistance

In systems where corrosion is a concern, the Male Union Elbow, often made from resistant materials, helps in maintaining the integrity of the connections. This is particularly important in marine or industrial applications where exposure to corrosive elements is high.

Flexible Hose Connections

The Male Union Elbow is frequently used with flexible hoses to provide a robust and leak-proof connection. This is especially useful in dynamic environments where vibrations and movements are common, ensuring that the system remains intact and functional.

Conclusion

The 3331872 Male Union Elbow is a versatile and reliable component that enhances the functionality and efficiency of various engine systems. Its role in connecting and redirecting fluid or gas flow is indispensable for the smooth operation of these systems.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Taghavifar, H., & Mardani, A. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Crolla, D. Crolla Encyclopedia. Wiley, 2015.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6312702.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6312702.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6312702.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6312702.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.