Minimum Quantity 10

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins S962E Draincock is a component designed for use in commercial truck maintenance. It plays a role in the efficient draining of fluids from the engine or other systems, contributing to the overall operation and maintenance of heavy-duty trucks. Understanding its function and importance can lead to better maintenance practices and enhanced truck performance.

Basic Concepts of Draincocks

A draincock is a valve used to release fluid from a system. It operates by allowing the fluid to flow out when the valve is opened, which is typically achieved by unscrewing or loosening a part of the valve. The general principle behind its operation is to provide a controlled means of emptying fluid systems, which is vital for maintenance and repair tasks. In vehicles, draincocks are important for maintaining fluid systems, ensuring that old or contaminated fluids can be removed and replaced, which helps in preserving the integrity and performance of the vehicle’s components 1.

Purpose of the S962E Draincock

The S962E Draincock is specifically designed to facilitate the draining of fluids such as coolant or oil from a truck’s engine or other systems. By providing a straightforward method to release these fluids, it aids in routine maintenance tasks like fluid changes. This process is important for removing old or contaminated fluids that could otherwise lead to decreased performance or damage to the engine and other components 2.

Key Features

The Cummins S962E Draincock is characterized by its design and the materials used in its construction. It is built to withstand the pressures and temperatures associated with heavy-duty truck engines, ensuring durability and reliable performance. Unique attributes may include a design that simplifies the draining process, materials that resist corrosion, and a construction that ensures a secure fit within the engine system.

Benefits

Using the S962E Draincock offers several advantages. It contributes to improved maintenance efficiency by providing a quick and easy way to drain fluids. This can lead to enhanced system performance, as regular fluid changes help maintain the optimal operation of the engine and other components. Additionally, effective fluid management through the use of a reliable draincock can contribute to the longevity of the truck’s components by preventing the buildup of contaminants that could lead to wear or damage 3.

Troubleshooting and Maintenance

Common issues with draincocks, including the S962E model, may involve leaks or difficulty in opening the valve. Troubleshooting steps can include checking for proper installation, ensuring the draincock is fully tightened when not in use, and inspecting for signs of wear or damage that may require replacement. Regular maintenance, such as cleaning around the draincock and ensuring it operates smoothly, can help prevent issues and ensure its longevity and proper function.

Cummins Engine Compatibility with S962E Draincock

The S962E Draincock, manufactured by Cummins, is designed to fit seamlessly into various Cummins engine models, ensuring efficient operation and longevity. Below is a detailed breakdown of the engine compatibility for the S962E Draincock:

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- B5.9 GAS PLUS CM556

- C8.3 G

- G5.9

- G8.3

- G855

- G855 CM558

- GTA38 G CMEICS G116C

- GTA8.3 CM558

- GTA855 CM558 (CM2358) G101

- ISV (Nissan)

- K19

- K38

- K50

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

- N14 CELECT

- N14 G

- N14 MECHANICAL

- NH/NT 855

- QSB5.9 CM850

- QSB6.7 M CM2250

Grouped Compatibility

For ease of reference, the engines have been grouped based on their series and model numbers:

- 4B3.9, 6B5.9, 6C8.3, B5.9 GAS PLUS CM556, C8.3 G, G5.9, G8.3, G855, G855 CM558, GTA38 G CMEICS G116C, GTA8.3 CM558, GTA855 CM558 (CM2358) G101, KTA19GC, KTA19GC CM558, KTA38GC CM558, QSB5.9 CM850, QSB6.7 M CM2250

- ISV (Nissan), K19, K38, K50

- N14 CELECT, N14 G, N14 MECHANICAL

- NH/NT 855

This comprehensive compatibility ensures that the S962E Draincock can be used across a wide range of Cummins engines, providing a reliable solution for maintaining the engine’s cooling system.

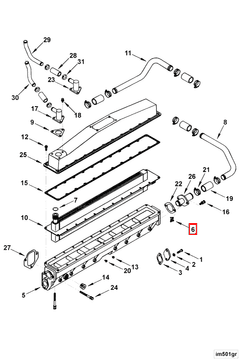

Role of S962E Draincock in Various Engine Components

The S962E Draincock is an essential component in several engine systems, facilitating the efficient drainage of fluids to maintain system integrity and performance. Here’s how it integrates with various components:

Air Systems

- Air Intercooler and Air Mounting Intercooler: The S962E ensures that any condensed water or debris within the intercooler systems is effectively drained, preventing buildup that could impair airflow and cooling efficiency.

Charge Air Systems

- Charge Air S/Assembly Cooler: In charge air systems, the draincock allows for the removal of moisture and contaminants from the cooler, ensuring optimal air density and compressor performance.

Cooling Systems

- Compressor Coolant Plumbing and Lubricating Oil Filter Cooler: These systems benefit from the S962E by enabling the periodic drainage of coolant and oil, which helps in maintaining the thermal efficiency and longevity of the components.

- Engine Oil Assembly Cooler: Regular drainage of old or contaminated oil ensures that the engine oil remains clean, reducing the risk of sludge formation and component wear.

- Exhaust Cooler Leak Test Kit: Though primarily a diagnostic tool, the integration of a draincock allows for the easy removal of test fluids, simplifying the maintenance process.

Lubrication Systems

- Lubricating Oil Cooler and T C Cooler: The draincock facilitates the drainage of oil, ensuring that the lubrication system operates with fresh, uncontaminated oil, which is vital for reducing friction and wear in moving parts.

- Marine SPO and Lubricating Oil Filter: In marine applications, the S962E is crucial for maintaining the purity of lubricating oil, which is exposed to harsh environmental conditions.

Transmission Systems

- Cooler, Torque Conv MTG: The draincock allows for the efficient drainage of transmission fluid, ensuring that the torque converter operates within optimal temperature ranges, thereby enhancing transmission durability and performance.

Water Systems

- Water Inlet Connection and Water Mounting Manifold: These components rely on the S962E to drain water and any accumulated sediments, preventing blockages and ensuring consistent water flow through the engine’s cooling circuits.

- Water Pump Arrangement and Water Transfer Vent Hose: Effective drainage through the draincock helps in maintaining the efficiency of the water pump and prevents airlocks in the cooling system.

Additional Components

- Expansion Tank, Filter and Cooler, Intercooler Assembly, Kit Spare (Heat Ex. Cooled), Lub Filter, Remote MTD. Oil Filter, Shaft and Bearing, TC Cooler: Across these diverse components, the S962E plays a role in ensuring that fluids are regularly drained, contaminants are removed, and system performance is maintained at peak levels.

Conclusion

In summary, the S962E Draincock is a versatile component that enhances the maintenance and operational efficiency of various engine systems by facilitating the regular drainage of fluids and contaminants. Its compatibility with a wide range of Cummins engines and its role in maintaining system integrity make it a valuable asset in the maintenance of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.