3638582

Draincock

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3638582 Draincock is a component designed for use in commercial trucks. It plays a significant role in the maintenance and operation of these vehicles by facilitating the draining of various fluids. This part is integral to ensuring that trucks operate efficiently and reliably, making it a key element in routine maintenance procedures.

Purpose and Function

The primary role of the Cummins 3638582 Draincock is to allow for the controlled release of fluids such as coolant, oil, or fuel from the truck’s system. This function is vital for regular maintenance tasks, including fluid changes and system flushes. The draincock operates through a simple yet effective mechanism: when opened, it creates a pathway for fluid to exit the system, and when closed, it ensures a secure seal to prevent leaks. Its operation is straightforward, typically involving a screw or lever that can be manipulated to open or close the valve 1.

Key Features

The Cummins 3638582 Draincock is constructed with materials such as brass or stainless steel, chosen for their durability and resistance to corrosion. These materials contribute to the draincock’s longevity and reliability under the demanding conditions encountered in commercial truck operations. The design of the draincock includes features that enhance its efficiency and ease of use, such as a threaded connection for secure attachment and a robust valve mechanism that ensures a tight seal when closed 2.

Benefits

Using the Cummins 3638582 Draincock offers several advantages. Its ease of use simplifies the process of draining fluids, reducing the time required for maintenance tasks. The reliability of the draincock ensures that fluid changes can be performed without the risk of leaks, contributing to the safety and efficiency of truck operations. Additionally, the durability of the materials used in its construction means that the draincock can withstand repeated use over time, providing long-term value 3.

Installation and Usage

Proper installation of the Cummins 3638582 Draincock involves ensuring a secure fit within the truck’s system, following manufacturer guidelines for torque specifications to avoid over-tightening, which could damage the component or the system it is attached to. To use the draincock for draining fluids, one should first ensure the truck is on a level surface and the engine is cool. Open the draincock slowly to allow fluid to exit the system, and once the desired amount of fluid has been drained, close the valve securely to prevent leaks.

Maintenance and Troubleshooting

To maintain the Cummins 3638582 Draincock and ensure optimal performance, regular inspections are recommended. This includes checking for signs of wear or corrosion and ensuring the valve operates smoothly. Common issues with draincocks may include leaks or difficulty in opening/closing the valve. Troubleshooting steps may involve tightening the connection, cleaning the valve, or, in cases of significant wear, replacing the draincock. Regular maintenance and timely replacements, when necessary, contribute to the overall efficiency and safety of truck operations.

Safety Considerations

When working with the Cummins 3638582 Draincock, it is important to follow safety protocols to protect against injuries and ensure the proper functioning of the component. This includes handling hot fluids with care to avoid burns and ensuring the draincock is properly sealed to prevent leaks. Adhering to manufacturer guidelines and safety standards is crucial for safe and effective use.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, with a history of innovation and commitment to quality. The company’s reputation is built on its dedication to producing reliable and efficient truck components. Cummins’ approach to manufacturing emphasizes the use of high-quality materials and advanced technologies to ensure that its products meet the rigorous demands of commercial truck operations.

Cummins Engine Part 3638582: Draincock Compatibility

The Cummins part 3638582, a Draincock, is a crucial component for managing and maintaining the fluid levels within various Cummins engine models. This part is designed to facilitate the drainage of fluids, such as coolant or oil, from the engine’s system, ensuring optimal performance and longevity.

Compatibility with Specific Engine Models

The Draincock part 3638582 is compatible with a wide range of Cummins engines, including:

- GTA38 G CMEICS G116C

- K19, K38, K50, KTA38GC CM558

- QSK38 CM2150 MCRS, QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108

- QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G

- QSK78 CM500

- QSK95 CM2350 K113

- QST30 CM2350 T101

- QSV81G, QSV91-G4 CM558/CM700 V102, QSV91G

This part ensures that the fluid drainage process is efficient and reliable across these engine models, contributing to the overall maintenance and operational efficiency of the engines.

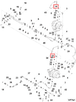

Role of Part 3638582 Draincock in Various Engine Systems

The part 3638582 Draincock is an essential component in several engine systems, facilitating the efficient drainage of fluids. Its application spans across various arrangements and assemblies, ensuring optimal performance and maintenance of the engine.

Aftercooler and Air Compressor Arrangements

In the aftercooler and air compressor arrangements, the Draincock allows for the periodic removal of condensed water and impurities. This is vital for maintaining the efficiency of the air compression process and preventing potential damage to the aftercooler.

Engine Oil Cooler and Torque Converter Oil Cooler

For the engine oil cooler and torque converter oil cooler, the Draincock provides a means to drain old oil, facilitating regular oil changes. This practice is important for preserving the lubrication properties of the oil and prolonging the life of the cooler components.

Turbocharger Arrangements and Plumbing

In turbocharger arrangements, particularly those involving turbocharger coolant plumbing, the Draincock is used to drain coolant. This helps in maintaining the correct coolant levels and preventing overheating of the turbocharger.

Water Pump and Auxiliary Cooling System

The Draincock is also integral to the water pump and auxiliary cooling system. It enables the drainage of water from the system, which is necessary for system maintenance and the replacement of coolant.

Compressor Water Supply Tube and Connections

For the compressor water supply tube and water outlet connections, the Draincock allows for the drainage of water, ensuring that the supply tube and connections remain free from sediment and scale buildup.

Thermostat and Support Assembly Housing

In the thermostat and support assembly housing, the Draincock is used to drain coolant. This is essential for thermostat maintenance and ensuring that the thermostat operates within the correct temperature range.

On Board Spares and Pump Kit

The Draincock is also a component in on board spares and pump kits. It provides a convenient way to drain fluids from these systems, aiding in their maintenance and ensuring they are ready for use when needed.

Intercooler Water Plumbing

In intercooler water plumbing, the Draincock is used to drain water from the intercooler. This is important for maintaining the efficiency of the intercooler and preventing waterlogging.

Base Parts and Engine Oil Assembly Cooler

Lastly, in base parts and engine oil assembly coolers, the Draincock is used for draining oil. This is a key maintenance step in ensuring the longevity and efficiency of these components.

Conclusion

The Cummins 3638582 Draincock is a vital component in the maintenance and operation of commercial trucks. Its design, featuring durable materials and a robust mechanism, ensures efficient and reliable fluid drainage across various engine systems. Regular maintenance and proper usage of this part contribute to the overall efficiency, safety, and longevity of truck operations.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩ -

Matthew Huang, Vehicle Crash Dynamics, CRC Press, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.