This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3079609 Draincock is a component designed for use in commercial trucks. It facilitates the draining of fluids such as coolant, oil, or fuel from the system. This part is integral to maintaining the operational efficiency and longevity of the truck’s engine and other fluid-dependent systems 3.

Basic Concepts of a Draincock

A draincock is a valve used to release fluid from a system. It is commonly found in various fluid systems, including automotive, industrial, and residential applications. The primary function of a draincock is to allow for the controlled release of fluid, which is necessary for maintenance, repair, or system purging. Draincocks are typically designed to be easy to operate, often featuring a simple screw or lever mechanism that can be manually actuated 1.

Purpose of the Cummins 3079609 Draincock

The Cummins 3079609 Draincock serves a specific role in the operation of commercial trucks by enabling the efficient draining of fluids. This is particularly important during maintenance procedures such as oil changes, coolant flushes, or fuel system draining. By providing a reliable means to remove fluids, the draincock helps ensure that the truck’s systems remain clean and free from contaminants, which can otherwise lead to decreased performance or system failure 2.

Key Features

The Cummins 3079609 Draincock is characterized by several key features that enhance its functionality. It is constructed from durable materials to withstand the pressures and temperatures associated with commercial truck fluid systems. The design includes a secure sealing mechanism to prevent leaks during operation and a user-friendly actuation method for ease of use. Additionally, the draincock may feature anti-corrosion coatings or treatments to prolong its service life in harsh operating environments 3.

Benefits

Using the Cummins 3079609 Draincock offers several advantages. Its robust construction ensures durability, reducing the need for frequent replacements. The ease of use, facilitated by its simple design, allows for quick and efficient fluid drainage, minimizing downtime during maintenance procedures. Furthermore, the secure sealing mechanism helps prevent fluid leaks, which can be hazardous and lead to system inefficiencies 1.

Installation Process

Installing the Cummins 3079609 Draincock involves several steps to ensure proper function and sealing. First, the area where the draincock will be installed should be cleaned to remove any debris or old sealant. The draincock should then be positioned and secured according to the manufacturer’s instructions, which may involve threading it into place or using a gasket for sealing. It is important to ensure that the draincock is tightened to the specified torque to prevent leaks 2.

Troubleshooting Common Issues

Common issues with draincocks can include leaks, difficulty in operation, or corrosion. To address leaks, check the sealing surfaces for damage and ensure the draincock is properly tightened. If operation is difficult, lubrication may be required, or the draincock may need to be replaced if it is corroded or damaged. Regular inspection and maintenance can help identify and resolve these issues before they lead to more significant problems 3.

Maintenance Tips

Regular maintenance of the Cummins 3079609 Draincock is key to ensuring its reliable operation. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the draincock and its surrounding area can prevent the buildup of debris that may interfere with its function. Additionally, applying a light coat of lubricant to the moving parts can facilitate easier operation and prolong the draincock’s service life 1.

Safety Considerations

When using and maintaining the Cummins 3079609 Draincock, it is important to follow safety practices to protect against injury and ensure the system’s integrity. This includes allowing fluids to cool before draining to avoid burns, using appropriate personal protective equipment (PPE) when handling hot fluids, and ensuring that the draincock is properly sealed to prevent leaks that could cause slips or environmental contamination 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the commercial truck industry. The company’s commitment to excellence and customer satisfaction has made it a preferred choice for commercial vehicle manufacturers and operators worldwide 3.

Cummins Part 3079609: Draincock for L10 GAS Engines

The Cummins part 3079609, a Draincock, is a component for the maintenance and operation of the L10 GAS engines. This part is designed to facilitate the removal of accumulated fluids, such as water or oil, from the engine’s crankcase or other components. Its proper installation and functionality are crucial for maintaining the engine’s efficiency and longevity 1.

The L10 GAS engine, known for its robust performance and reliability, benefits significantly from the inclusion of the Draincock. By allowing for the easy drainage of unwanted fluids, the Draincock helps prevent contamination and potential damage to the engine. This is particularly important in environments where the engine may be exposed to varying temperatures and moisture levels 2.

In the context of the L10 GAS engine, the Draincock is strategically placed to ensure that it can effectively serve its purpose without interfering with other engine components. Its design and placement are critical to ensuring that the engine operates smoothly and efficiently. Regular maintenance involving the use of the Draincock is recommended to keep the engine in optimal condition 3.

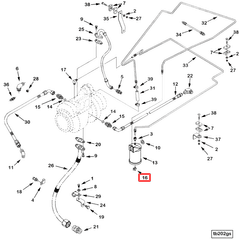

Role of Part 3079609 Draincock in Plumbing and Turbocharger Systems

Plumbing Systems

In plumbing systems, the Draincock (part 3079609) is instrumental in facilitating the efficient drainage of water and other fluids. It is commonly integrated into various plumbing fixtures and appliances, such as water heaters, boilers, and radiators. The Draincock allows for the periodic release of accumulated sediment, debris, and water, which helps maintain the system’s efficiency and longevity. Regular use of the Draincock prevents buildup that could lead to corrosion, reduced efficiency, and potential system failures. Additionally, it aids in system maintenance by allowing for easier access during inspections and cleaning procedures 1.

Turbocharger Systems

Within turbocharger systems, the Draincock (part 3079609) plays a significant role in managing the lubrication and cooling processes. Turbochargers operate under extreme conditions, generating high temperatures and pressures. The Draincock is typically installed in the lubrication system to allow for the periodic draining of oil. This ensures that the oil remains clean and free from contaminants, which is essential for the turbocharger’s bearings and other moving parts. Regular drainage helps maintain optimal lubrication, reducing wear and tear and enhancing the turbocharger’s performance and reliability. Furthermore, the Draincock assists in the removal of any water or other impurities that may accumulate in the oil, further protecting the turbocharger from damage 2.

Conclusion

The Cummins 3079609 Draincock is a vital component in the maintenance and operation of commercial trucks, particularly for the L10 GAS engines. Its role in facilitating the efficient drainage of fluids ensures the cleanliness and longevity of the engine and other fluid-dependent systems. Regular maintenance and proper installation of this part are essential for optimal performance and reliability of the vehicle 3.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book: Powertrain. Springer.

↩ ↩ ↩ ↩ ↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ ↩ ↩ ↩ ↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles (Second Edition). SAE International.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.