This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

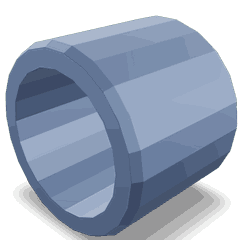

The Cummins 4982139 Ring Dowel is a specialized component designed for use in heavy-duty truck applications. Its purpose is to ensure precise alignment and secure positioning of various engine or transmission components. The significance of this part lies in its ability to maintain the integrity and efficiency of the mechanical assemblies it supports 1.

Basic Concepts of Ring Dowels

A ring dowel is a cylindrical component used in mechanical assemblies to provide alignment and support between mating parts. In the context of heavy-duty trucks, ring dowels play a role in ensuring that components are correctly positioned relative to each other, which is vital for the proper functioning of the engine or transmission system 2. They operate by fitting into corresponding holes in adjacent parts, thereby maintaining the required spacing and alignment.

Purpose of the Cummins 4982139 Ring Dowel

The Cummins 4982139 Ring Dowel serves a specific function within the truck’s engine or transmission system. It ensures that components are aligned correctly, which is important for the efficient operation of the system. By providing a stable and consistent interface between parts, this ring dowel contributes to the overall reliability and performance of the truck 3.

Key Features

The Cummins 4982139 Ring Dowel is characterized by several key features that enhance its performance. It is typically made from high-quality materials that offer durability and resistance to wear. The design of the ring dowel includes precise dimensions to ensure a snug fit within the corresponding holes. Additionally, it may feature unique attributes such as anti-rotational properties to prevent misalignment during operation 4.

Benefits

The advantages provided by the Cummins 4982139 Ring Dowel include improved alignment of mechanical components, which leads to enhanced durability and overall system efficiency. By ensuring that parts are correctly positioned, this ring dowel helps to reduce wear and tear, thereby extending the lifespan of the engine or transmission system. Additionally, it contributes to smoother operation and better performance of the truck 5.

Installation Process

Proper installation of the Cummins 4982139 Ring Dowel involves several steps to ensure correct placement and function. Begin by cleaning the mating surfaces to remove any debris or old lubricants. Use the appropriate tools to insert the ring dowel into the designated hole, ensuring it is seated properly. Verify the alignment of the components to confirm that the ring dowel is performing its intended function. Follow best practices to avoid damage during installation 6.

Common Issues and Troubleshooting

Common problems associated with ring dowels can include misalignment, wear, or damage. These issues may arise due to improper installation, excessive wear over time, or exposure to harsh operating conditions. Troubleshooting steps involve inspecting the ring dowel and mating surfaces for signs of wear or damage, ensuring correct alignment, and replacing the ring dowel if necessary to restore proper function 7.

Maintenance Tips

Regular maintenance of the Cummins 4982139 Ring Dowel includes periodic inspection to check for signs of wear or damage. Cleaning the ring dowel and mating surfaces can help prevent buildup of debris that may affect performance. If significant wear is observed, consider replacement to maintain the integrity of the engine or transmission system. Adhering to manufacturer recommendations for maintenance intervals will help ensure the longevity and reliability of the component 8.

Role in Engine or Transmission System

The Cummins 4982139 Ring Dowel interacts with other components within the engine or transmission system by providing a stable and precise interface. Its role in maintaining alignment and spacing between parts is important for the efficient operation of the system. By ensuring that components are correctly positioned, this ring dowel contributes to the overall performance and reliability of the truck 9.

Historical Development

The evolution of ring dowels in heavy-duty truck applications has seen significant advancements in design and materials over time. Early versions were made from basic materials and offered limited precision. Modern ring dowels, like the Cummins 4982139, are crafted from high-quality materials and feature precise dimensions to enhance performance and durability. These improvements have contributed to the increased reliability and efficiency of heavy-duty trucks 10.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing history in the heavy-duty truck industry. The company offers a wide range of products, including engines, transmissions, and aftermarket parts, known for their quality and performance. Cummins has built a reputation for innovation and reliability, making it a trusted name in the industry. The Cummins 4982139 Ring Dowel is part of their comprehensive product line designed to meet the demanding requirements of heavy-duty applications 11.

Compatibility

The Cummins Ring Dowel part number 4982139 is a critical component in several engine models, ensuring proper alignment and stability of the piston rings within the engine cylinder. This part is integral to maintaining engine performance and longevity.

B3.3 Engine Series

The B3.3 engine series, known for its reliability and efficiency, utilizes the Ring Dowel part 4982139. This part is essential in maintaining the precise alignment of the piston rings, which is crucial for optimal engine operation. The B3.3 engines are often found in various applications, including agricultural and industrial machinery, where durability and performance are paramount.

In the B3.3 engine series, the Ring Dowel part 4982139 ensures that the piston rings maintain their correct position relative to the cylinder walls. This alignment is vital for minimizing friction, reducing wear, and maximizing the engine’s efficiency. The use of this specific part number across different models within the B3.3 series highlights its importance in maintaining the engine’s overall integrity and performance.

The compatibility of the Ring Dowel part 4982139 with the B3.3 engine series underscores its role in supporting the engine’s mechanical functions. This part’s precision and durability make it a key component in ensuring the engine’s smooth operation and longevity.

Role in Engine Systems

The part 4982139 Ring Dowel is an essential component in ensuring the precise alignment and secure fitting of various engine components. Its primary function is to maintain the correct positional relationship between the block and the cylinder block, which is fundamental for the engine’s performance and durability.

When integrating the Ring Dowel into an engine system, it is positioned within the block to align the cylinder block accurately. This alignment is vital for the uniform distribution of forces and the prevention of undue stress on the engine components.

In the context of a long block assembly, the Ring Dowel ensures that the main bearing cap is correctly aligned with the cylinder block. This alignment is necessary for the proper installation of the main bearings, which support the crankshaft and are subject to significant rotational forces.

The precise fitting afforded by the Ring Dowel contributes to the overall stability and efficiency of the engine. It helps in maintaining the integrity of the engine’s structural components, ensuring that they operate within their designed parameters. This, in turn, enhances the engine’s reliability and performance over its operational lifespan.

Conclusion

The Cummins 4982139 Ring Dowel is a critical component in heavy-duty truck applications, ensuring precise alignment and secure positioning of engine and transmission components. Its role in maintaining the integrity and efficiency of mechanical assemblies is paramount. By understanding the key features, benefits, and proper installation procedures of this part, technicians and engineers can enhance the performance and reliability of heavy-duty trucks.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.