3082438

Ring Dowel

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3082438 Ring Dowel is a specialized component designed for use in heavy-duty truck engines. Its purpose is to ensure precise alignment and secure positioning of various engine components, contributing to the overall efficiency and reliability of the truck’s powertrain. Understanding the role and significance of this part is vital for maintaining and optimizing the performance of heavy-duty vehicles.

Basic Concepts of Ring Dowels

A ring dowel is a cylindrical pin used in mechanical assemblies to align and position components accurately. It operates by fitting into corresponding holes in mating parts, ensuring they are correctly aligned during assembly. This alignment is crucial for the proper functioning of mechanical systems, as it helps maintain the integrity of the assembly and ensures that components work together seamlessly 1.

Purpose of the 3082438 Ring Dowel

The Cummins 3082438 Ring Dowel plays a specific role in the operation of a truck by ensuring the accurate alignment of engine components. It is typically used in the engine block or cylinder head to maintain the correct spacing and orientation of parts such as bearings, gaskets, and other critical components. This precise alignment is necessary for the engine to function efficiently and reliably, reducing the risk of wear, leakage, or failure 2.

Key Features

The Cummins 3082438 Ring Dowel is characterized by several key features that contribute to its effectiveness. It is typically made from high-strength materials such as steel or stainless steel, ensuring durability and resistance to wear. The dowel is designed with precise dimensions to fit snugly into the corresponding holes, providing a secure and stable connection. Additionally, its surface may be treated to enhance corrosion resistance and improve longevity in harsh operating environments 3.

Benefits

Using the Cummins 3082438 Ring Dowel offers several advantages. It provides improved alignment of engine components, which can enhance the overall performance and reliability of the engine. The precise positioning facilitated by the dowel helps reduce wear on mating parts, leading to longer component life. Additionally, by ensuring proper alignment, the dowel can contribute to more efficient engine operation, potentially leading to cost savings over time through reduced maintenance and repair needs 4.

Installation Process

Proper installation of the Cummins 3082438 Ring Dowel is critical for ensuring its effectiveness. The process typically involves cleaning the mating surfaces to remove any debris or old gasket material. The dowel is then inserted into the designated hole, ensuring it fits securely and flush with the surface. Tools such as a press or mallet may be required to seat the dowel properly. It is important to follow the manufacturer’s guidelines to ensure correct installation and avoid damage to the component or surrounding parts 5.

Common Issues and Troubleshooting

Typical problems that may arise with the Cummins 3082438 Ring Dowel include misalignment during installation, corrosion, or wear over time. Misalignment can often be corrected by re-evaluating the installation process and ensuring all components are properly positioned. Corrosion can be addressed by cleaning the affected areas and applying a protective coating. Wear may require replacement of the dowel to maintain proper alignment and function 6.

Maintenance Tips

Regular maintenance practices can help ensure the longevity and optimal performance of the Cummins 3082438 Ring Dowel. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the dowel and surrounding areas can prevent buildup of debris that may affect alignment. Additionally, ensuring that all mating surfaces are clean and free of contaminants during reassembly can help maintain the integrity of the alignment provided by the dowel 7.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industry. The company is known for its commitment to quality, innovation, and reliability in engine and component design. Cummins’ history of producing high-performance, durable parts has established them as a trusted name in the industry, providing customers with confidence in the components they use in their vehicles 8.

Compatibility of Ring Dowel Part 3082438 with Cummins Engines

The Ring Dowel part 3082438, manufactured by Cummins, is designed to fit a variety of Cummins engines. Here is a detailed look at its compatibility across different engine models:

QSK45 CM500 and QSK60 CM500

The Ring Dowel part 3082438 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and reliability in heavy-duty applications.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

This particular dowel also fits the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines. These engines are part of the QSK series, which is designed for demanding applications, offering high performance and durability.

QSK60G

The QSK60G engine is another model that is compatible with the Ring Dowel part 3082438. This engine is part of the same series, ensuring that the dowel fits seamlessly into the engine’s design.

QSK78 CM500 and QSK95 CM2350 K110, QSK95 CM2350 K113

Lastly, the Ring Dowel part 3082438 is also suitable for the QSK78 CM500, QSK95 CM2350 K110, and QSK95 CM2350 K113 engines. These engines, like the others mentioned, are part of Cummins’ QSK series, which is renowned for its reliability and efficiency in various industrial applications.

This compatibility ensures that the Ring Dowel part 3082438 can be used across a range of Cummins engines, providing a reliable and consistent fit for maintenance and repair purposes.

Role of Part 3082438 Ring Dowel in Engine Systems

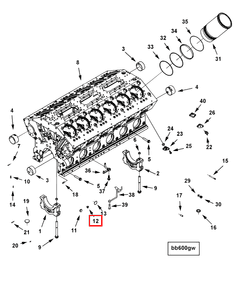

The part 3082438 Ring Dowel is instrumental in ensuring the precise alignment and secure fitting of various components within engine systems. Its application is particularly significant in the assembly and maintenance of the Cylinder Block and Cylinder Block Kit.

In the Cylinder Block, the Ring Dowel aids in the accurate positioning of the Crankshaft and Bearings, ensuring that they are correctly aligned with the block’s bores. This alignment is essential for the smooth operation of the engine, as it prevents undue stress on the crankshaft and bearings, which could lead to premature wear or failure.

When integrating the Cylinder Block Hardware Kit or the Service Block Kit, the Ring Dowel plays a role in maintaining the structural integrity of the assembly. It ensures that all components, including the Cam Follower Lever and Gear Housing, are correctly aligned with the cylinder block. This is particularly important in high-performance engines where even minor misalignments can significantly impact engine efficiency and longevity.

Furthermore, in the context of the Block and Design Alternative components, the Ring Dowel contributes to the overall stability and reliability of the engine system. It facilitates the proper installation of the Follower and Cam components, which are vital for the valve train’s operation.

In summary, the 3082438 Ring Dowel is a key component in the precise assembly and maintenance of engine systems, ensuring that all interconnected parts function harmoniously and efficiently.

Conclusion

The Cummins 3082438 Ring Dowel is a critical component in the maintenance and optimization of heavy-duty truck engines. Its role in ensuring precise alignment and secure positioning of engine components contributes significantly to the overall efficiency and reliability of the powertrain. Understanding and properly maintaining this part is essential for the longevity and performance of heavy-duty vehicles.

-

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Cummins Inc. (n.d.). Service Manual (5504636).

↩ -

Cummins Inc. (n.d.). Service Manual (5504636).

↩ -

Cummins Inc. (n.d.). Service Manual (5504636).

↩ -

Cummins Inc. (n.d.). Service Manual (5504636).

↩ -

Cummins Inc. (n.d.). Service Manual (5504636).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.