5300777

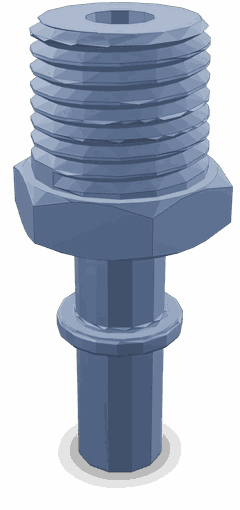

Quick Disconnect Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5300777 Quick Disconnect Connector is a specialized component designed for use in commercial truck operations. It facilitates the easy connection and disconnection of fluid lines, which is vital for routine maintenance and operational efficiency. This connector is part of Cummins Inc.’s extensive range of products aimed at enhancing the performance and reliability of commercial vehicles.

Basic Concepts of Quick Disconnect Connectors

Quick disconnect connectors are devices used in the automotive industry to allow for the rapid connection and disconnection of fluid lines without the need for tools 1. They are commonly employed in systems involving hydraulics, fuel, and other fluids. These connectors enhance operational efficiency by reducing the time required for maintenance tasks and minimizing the risk of fluid leaks during disconnection.

Purpose and Role in Truck Operation

The Cummins 5300777 Quick Disconnect Connector plays a role in the operation of commercial trucks by enabling the quick and secure connection and disconnection of fluid lines. This functionality is particularly beneficial during maintenance procedures, allowing technicians to perform tasks more efficiently. The connector ensures a secure seal when connected, which helps prevent fluid leaks and maintains system integrity.

Key Features

The Cummins 5300777 Quick Disconnect Connector is characterized by its robust design and the use of high-quality materials. It features a durable housing that protects internal components from wear and environmental factors. The connector also includes a sealing mechanism that ensures a tight connection, reducing the likelihood of leaks. Additionally, it is designed for easy operation, allowing for quick disconnection with a simple push-button mechanism.

Benefits

The use of the Cummins 5300777 Quick Disconnect Connector offers several advantages. It saves time during maintenance by allowing for rapid connection and disconnection of fluid lines. This efficiency can lead to reduced downtime for commercial trucks. The connector also helps minimize fluid leaks, which can enhance safety and reduce the risk of environmental contamination. Furthermore, its design contributes to improved safety for operators by simplifying the maintenance process and reducing the need for complex tools.

Installation Process

Installing the Cummins 5300777 Quick Disconnect Connector involves several steps to ensure proper function and safety. First, the fluid line should be prepared by cleaning and, if necessary, cutting to the appropriate length. The connector is then attached to the fluid line, ensuring a secure fit. Once installed, the connection should be tested for leaks by pressurizing the system and observing for any signs of fluid escape. It is important to follow manufacturer guidelines to avoid common installation pitfalls, such as improper alignment or insufficient tightening.

Troubleshooting Common Issues

Common issues with quick disconnect connectors may include leaks, difficulty in disconnection, or connector damage. To address leaks, inspect the sealing surfaces for debris or damage and ensure the connector is properly aligned and tightened. If disconnection is difficult, check for obstructions or seized components and lubricate if necessary. Damaged connectors should be replaced to maintain system integrity and safety.

Maintenance Tips

Regular maintenance of the Cummins 5300777 Quick Disconnect Connector is important for ensuring its longevity and reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the connector and sealing surfaces to remove contaminants, and lubricating moving parts as recommended by the manufacturer. Adhering to these practices can help prevent issues and extend the service life of the connector.

Safety Considerations

When working with quick disconnect connectors, it is important to follow safety protocols to protect both the operator and the equipment. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before disconnection, and handling the connector with care to avoid damage. Proper storage and disposal practices should also be observed to maintain safety and environmental standards.

Compatibility of Cummins Part 5300777 with Various Cummins Engines

The Cummins part 5300777, a Quick Disconnect Connector, is designed to fit seamlessly with a range of Cummins engines, ensuring efficient and reliable operation. This part is integral to the functionality of several engine models, providing a critical connection point for various systems.

ISL G CM2180

The ISL G CM2180 engine benefits from the 5300777 Quick Disconnect Connector, which is engineered to meet the specific requirements of this engine model. This connector ensures that the engine’s systems can be easily and safely disconnected and reconnected, facilitating maintenance and repairs.

QSB6.7 CM850 (CM2850)

For the QSB6.7 CM850 (CM2850) engine, the 5300777 Quick Disconnect Connector is a vital component. It is designed to handle the unique demands of this engine, providing a robust and reliable connection that enhances the engine’s overall performance and durability.

QSB7 CM2880 B117

The QSB7 CM2880 B117 engine also incorporates the 5300777 Quick Disconnect Connector. This part is tailored to fit the specific design and operational needs of this engine model, ensuring that the connection remains secure and efficient under various operating conditions.

Grouping of Engines

The engines listed—ISL G CM2180, QSB6.7 CM850 (CM2850), and QSB7 CM2880 B117—are all part of Cummins’ extensive range of diesel engines. The 5300777 Quick Disconnect Connector is designed to be compatible with these models, providing a standardized solution for connecting and disconnecting systems across different engine types.

Role of Part 5300777 Quick Disconnect Connector in Engine Systems

The part 5300777 Quick Disconnect Connector is integral to the efficient operation of various engine systems, facilitating seamless connections and disconnections in critical fluid pathways.

In the compressor coolant system, the Quick Disconnect Connector allows for easy maintenance and service by enabling quick detachment and reattachment of the coolant lines. This feature is particularly beneficial during routine inspections or when replacing components, as it minimizes downtime and reduces the complexity of the service procedure.

Within the water inlet system, the connector ensures a secure and leak-free connection between the water inlet and the engine’s cooling passages. This is essential for maintaining consistent coolant flow, which is vital for regulating engine temperature and preventing overheating.

The arrangement of these connectors throughout the engine system enhances overall reliability and serviceability. By standardizing connection points, the Quick Disconnect Connector simplifies the replacement of worn or damaged hoses and fittings, contributing to the longevity and performance of the engine.

Conclusion

In summary, the integration of the Cummins 5300777 Quick Disconnect Connector into these systems underscores its importance in maintaining operational efficiency and facilitating easier maintenance procedures. The connector’s robust design, ease of use, and compatibility with various Cummins engines make it a valuable component in the maintenance and operation of commercial trucks.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.