4918432

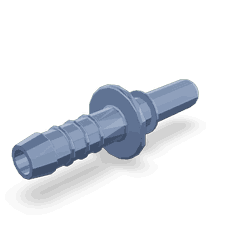

Quick Disconnect Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4918432 Quick Disconnect Connector is a specialized component designed for use in commercial trucks. It facilitates the efficient and secure connection and disconnection of fluid transfer systems, which are integral to the operation of these vehicles. This connector is significant in maintaining the functionality and reliability of truck systems by ensuring seamless fluid transfer 3.

Basic Concepts of Quick Disconnect Connectors

Quick disconnect connectors are devices used to join and separate fluid lines quickly and safely. They are employed across various industries, including automotive, aerospace, and manufacturing, to streamline processes that involve fluid transfer. In commercial trucking, these connectors are vital for systems such as fuel, hydraulic, and coolant lines, allowing for rapid and secure connections that enhance operational efficiency and safety 1.

Purpose of the 4918432 Quick Disconnect Connector

The 4918432 Quick Disconnect Connector is specifically designed to play a role in the fluid transfer systems of trucks. It is applied in scenarios where quick and reliable connections are necessary, such as during maintenance or when switching between different fluid sources. This connector ensures that the transfer of fluids like fuel, hydraulic fluid, and coolant is conducted without leaks, thereby maintaining system integrity and performance 3.

Key Features

The 4918432 Quick Disconnect Connector boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The design includes robust locking mechanisms that secure the connection, preventing accidental disconnections. Additionally, the connector is engineered to minimize leaks, featuring precision-machined components that ensure a tight seal 2.

Benefits of Using the 4918432 Quick Disconnect Connector

Utilizing the 4918432 Quick Disconnect Connector offers several advantages. It simplifies the process of connecting and disconnecting fluid lines, reducing the time required for maintenance tasks. The secure connection it provides minimizes the risk of leaks, which can be hazardous and inefficient. Furthermore, the ease of use enhances safety by allowing technicians to perform connections and disconnections quickly and with confidence 1.

Installation Process

Installing the 4918432 Quick Disconnect Connector involves several steps to ensure a secure and efficient connection. First, the appropriate fluid line should be prepared and cleaned. The connector is then aligned with the line and pushed onto the fitting until it clicks into place, indicating a secure connection. Tools such as wrenches may be required to ensure the connection is tight. It is important to follow manufacturer guidelines to achieve the best results 3.

Troubleshooting Common Issues

Common issues with the 4918432 Quick Disconnect Connector may include leaks or difficulty in disconnecting. If a leak is detected, the connection should be inspected for proper seating and any signs of damage. Ensuring that the connector is fully engaged can often resolve this issue. Difficulty in disconnecting may be addressed by ensuring that the release mechanism is properly operated and that there are no obstructions preventing disconnection 2.

Maintenance Tips

Regular maintenance of the 4918432 Quick Disconnect Connector is crucial for ensuring its longevity and reliable performance. This includes periodic cleaning to remove any buildup that may affect the seal, inspecting for signs of wear or damage, and replacing the connector if it shows signs of deterioration. Adhering to these maintenance practices will help prevent issues and ensure the connector continues to function effectively 1.

Safety Considerations

When working with the 4918432 Quick Disconnect Connector, it is important to observe several safety practices. This includes ensuring that the area is well-ventilated when dealing with fluid transfers, wearing appropriate personal protective equipment, and following all manufacturer guidelines for installation and maintenance. Additionally, being aware of the pressure and type of fluid being transferred can help prevent accidents and ensure a safe working environment 2.

Cummins Corporation

Cummins Corporation is a renowned manufacturer with a rich history in the commercial trucking industry. The company offers a wide range of products, including engines, filtration systems, and components like the 4918432 Quick Disconnect Connector. Cummins is known for its commitment to quality and innovation, providing solutions that enhance the performance and reliability of commercial vehicles 3.

Role of Part 4918432 Quick Disconnect Connector in Engine Systems

The 4918432 Quick Disconnect Connector is integral to the seamless operation and maintenance of various engine systems. It facilitates efficient connections and disconnections in several diagnostic and testing procedures, enhancing both the ease and safety of these processes.

Integration with Diagnostic and Testing Kits

- Diagnostic Kit: The Quick Disconnect Connector is used to swiftly connect and disconnect various diagnostic tools, allowing for rapid assessment and troubleshooting of engine components.

- Doser Pressure Test Kit: This connector enables quick attachment and detachment of pressure testing equipment, ensuring accurate pressure readings without the need for complex setups.

- Shut-Off Valve Test Kit: It allows for the easy connection of shut-off valves during testing, providing a secure and leak-free seal that is essential for precise measurements.

- Leak Test Kit: The connector is employed to link leak detection instruments, streamlining the process of identifying and addressing leaks within the engine system.

- Fuel System Leak Tester: It ensures a tight connection between the tester and the fuel system, facilitating accurate leak detection and minimizing the risk of fuel spillage.

Use in Installation and Certification Kits

- Engine Installation Kit: During engine installation, the Quick Disconnect Connector simplifies the connection of various hoses and components, reducing installation time and enhancing safety.

- B-Tier-3 CTF Tool Kit: This tool kit benefits from the connector’s ability to quickly link components, allowing for efficient performance testing and calibration.

- ISB Certification Kit and MR Certification Kit: These kits require precise and secure connections for certification testing. The Quick Disconnect Connector ensures that all components are linked correctly, maintaining the integrity of the testing process.

Application in Hoses and Adapters

- Flexible Hose: The connector is used to join flexible hoses to rigid components, providing a secure yet easily detachable connection that is vital for maintenance and repair.

- Leak Test Hose: It allows for the rapid connection of leak test hoses to the engine system, ensuring that tests are conducted efficiently and accurately.

- Pressure Gauge Adapter: The connector facilitates the attachment of pressure gauges, enabling precise measurement of system pressures without the complications of permanent fittings.

Utility in Plugs and Packages

- Leak Test Plug: The Quick Disconnect Connector is used to seal off sections of the engine system during leak testing, ensuring that tests are conducted in a controlled environment.

- Product Installation Package: It is included in installation packages to provide a standardized method for connecting various components, ensuring consistency across installations.

Conclusion

The 4918432 Quick Disconnect Connector plays a significant role in enhancing the efficiency, safety, and accuracy of engine system diagnostics, testing, and installation procedures. Its versatile application across various kits and components underscores its importance in maintaining and optimizing engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.