3030207

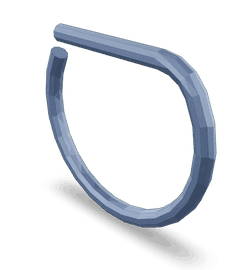

Dipstick Retainer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3030207 Dipstick Retainer is a component designed to secure the dipstick in place within the engine system of commercial trucks. Its purpose is to ensure that the dipstick remains properly positioned, facilitating accurate oil level readings and contributing to the overall maintenance and operation of the vehicle.

Basic Concepts of Dipstick Retainers

A dipstick retainer is a small but vital part of the engine system. Its primary function is to hold the dipstick in place, allowing for consistent and reliable oil level measurements. The dipstick, in turn, plays a role in the engine’s lubrication system by providing a means to check the oil level without dismantling the engine. The retainer interacts with the dipstick and the engine block, ensuring that the dipstick is correctly aligned and secured 1.

Purpose of the 3030207 Dipstick Retainer

The 3030207 Dipstick Retainer plays a role in the operation of a truck by securing the dipstick, which is used to measure the oil level in the engine. Accurate oil level readings are important for maintaining engine health, as they allow for timely oil changes and help prevent engine damage due to low oil levels. By ensuring the dipstick remains in place, the retainer contributes to the reliability and efficiency of the engine’s lubrication system 2.

Key Features

The Cummins 3030207 Dipstick Retainer is constructed with durability and functionality in mind. It is made from high-quality materials that can withstand the harsh conditions of commercial truck engines. The design ensures a secure fit for the dipstick, and its construction is robust enough to endure frequent use without degradation. Unique attributes may include a corrosion-resistant coating and a design that allows for easy installation and removal.

Benefits of Using the 3030207 Dipstick Retainer

The advantages of using the 3030207 Dipstick Retainer include enhanced durability, which is crucial for components exposed to the demanding environment of a commercial truck engine. Its design facilitates ease of use, allowing for quick and accurate oil level checks. The retainer’s reliability in harsh operating conditions ensures that it performs consistently over time, contributing to the overall maintenance of the engine 3.

Installation Process

Installing the 3030207 Dipstick Retainer involves a few straightforward steps. First, ensure the engine is cool and the oil has settled. Then, remove the old retainer if present. Align the new retainer with the dipstick tube and secure it in place. Tools required may include a socket wrench for any fasteners. It is important to follow the manufacturer’s instructions to ensure a proper fit and function.

Troubleshooting Common Issues

Common problems with dipstick retainers can include leaks around the retainer or difficulty in reading oil levels accurately. To address leaks, check the seal between the retainer and the engine block, and ensure there is no damage to the retainer itself. If oil level readings are inconsistent, verify that the dipstick is fully seated and that the retainer is secure. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

To prolong the life of the 3030207 Dipstick Retainer, regular maintenance is recommended. This includes cleaning the retainer and dipstick to remove any buildup that could affect readings. Inspect the retainer for signs of wear or damage during routine oil changes. If the retainer shows signs of corrosion or if it becomes difficult to remove the dipstick, consider replacement to ensure accurate oil level readings and maintain engine health.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of diesel engines and related technologies. With a history of innovation and a commitment to quality, Cummins has built a reputation for producing reliable and efficient engine components. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Cummins Dipstick Retainer 3030207 Compatibility

The Cummins Dipstick Retainer part number 3030207 is designed to fit a variety of engines within the Cummins engine lineup. This part is crucial for maintaining the integrity and functionality of the engine’s oil level checking system. Below is a detailed breakdown of the engines with which this dipstick retainer is compatible:

L Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

M Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

N Series Engines

- N14 MECHANICAL

QSK Series Engines

- QSK19 CM2350 K114

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- QSK45 CM500

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

K Series Engines

- K19

- K38

- K50

GTA38 Series Engines

- GTA38 G CMEICS G116C

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

KTA38 Series Engines

- KTA38GC CM558

This dipstick retainer ensures that the dipstick remains securely in place, preventing accidental loss or damage, which is critical for maintaining the engine’s oil levels and overall performance.

Role of Part 3030207 Dipstick Retainer in Engine Systems

The Part 3030207 Dipstick Retainer is an essential component in the arrangement of various engine systems, ensuring the proper functioning and maintenance of the engine. Its primary role is to secure the dipstick within the dipstick tube, which is integral to the oil fill and breather system.

Integration with Engine Components

-

Oil Fill and Breather System: The dipstick retainer holds the dipstick in place within the dipstick tube, which is connected to the oil fill and breather arrangement. This system allows for the accurate measurement of oil levels and facilitates the venting of crankcase gases.

-

Cylinder Block and Cover: Positioned on the cylinder block cover or hand hole cover, the dipstick retainer ensures that the dipstick remains accessible for regular oil level checks. This is vital for maintaining optimal oil levels within the crankcase.

-

Oil Pan and Crankcase: The dipstick tube, secured by the retainer, extends into the oil pan, allowing mechanics to gauge the oil level within the crankcase. This is important for preventing oil starvation and ensuring lubrication of engine components.

-

Hand Hole Cover: Often located on the hand hole cover, the dipstick retainer provides a secure point for the dipstick, making it easier for engineers and mechanics to perform routine maintenance checks without disassembling the cover.

-

Oil Level Gauge and EBM (Electronic Brake Module) Integration: In systems where an oil level gauge or EBM is used, the dipstick retainer ensures that the dipstick remains in the correct position for accurate readings. This is particularly important in modern engines where precise oil levels are monitored electronically.

-

Filter Kit and Oil Gauge Tube: When installing a filter kit or replacing the oil gauge tube, the dipstick retainer plays a role in maintaining the integrity of the oil level measurement system. It ensures that the dipstick does not become dislodged during these procedures.

-

Product Installation and Package: During the installation of new engine components or when replacing the dipstick and related hardware, the dipstick retainer is a key part that must be correctly installed to ensure the dipstick functions as intended.

Conclusion

In summary, the 3030207 Dipstick Retainer is a fundamental component in the maintenance and operation of engine systems, facilitating accurate oil level measurements and ensuring the dipstick remains securely in place within the dipstick tube. Regular maintenance and proper installation of this Cummins part are essential for the efficient and reliable operation of commercial truck engines.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.