This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

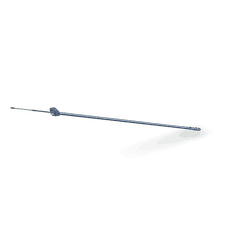

The Cummins 5561713 Dipstick is a specialized tool designed for use in heavy-duty trucks. Its primary function is to facilitate the measurement of oil levels within the engine, ensuring that the engine operates within optimal parameters. Regular monitoring of oil levels is a fundamental aspect of engine maintenance, contributing to the longevity and efficiency of the vehicle 4.

Basic Concepts of a Dipstick

A dipstick is a thin, graduated metal or plastic rod used to measure the level of fluid in an engine. It operates on a simple principle: the dipstick is inserted into the engine’s oil sump, and when withdrawn, the oil level is indicated by the marking on the dipstick that corresponds to the oil’s height. This measurement is crucial for assessing whether the engine has sufficient lubrication, which is vital for its operation and longevity 1.

Purpose of the Cummins 5561713 Dipstick

The Cummins 5561713 Dipstick plays a specific role in the operation and maintenance of a truck’s engine. It is used to check the oil level, ensuring that there is adequate lubrication for the engine’s moving parts. Proper lubrication is necessary to reduce friction, wear, and heat, all of which can adversely affect engine performance and lifespan 2.

Key Features

The Cummins 5561713 Dipstick is characterized by its robust design and the materials used in its construction. It is typically made from high-quality steel, which offers durability and resistance to the high temperatures and pressures within an engine. The dipstick is also marked with clear, easy-to-read graduations for accurate oil level measurement. Additionally, it may feature a handle for ease of use and a spring-loaded cap to prevent oil leaks when not in use.

Benefits of Using the Cummins 5561713 Dipstick

Utilizing the Cummins 5561713 Dipstick offers several advantages. Its design ensures accurate measurement of oil levels, which is crucial for maintaining engine health. The durability of the dipstick means it can withstand the demanding conditions within a heavy-duty truck engine. Furthermore, its ease of use simplifies the process of checking oil levels, making it a practical tool for regular maintenance routines 3.

Troubleshooting and Maintenance Suggestions

Common issues with dipsticks can include inaccurate readings due to wear or damage. To troubleshoot, ensure the dipstick is fully seated in its tube and check for any visible damage. Regular cleaning of the dipstick can prevent buildup that may affect readings. For maintenance, store the dipstick in a clean, dry place when not in use, and replace it if it shows signs of wear or if accuracy is in question.

Installation and Usage Guidelines

Proper installation and usage of the Cummins 5561713 Dipstick involve a few key steps. First, ensure the engine is off and has had time to cool to avoid burns from hot oil. Remove the dipstick by unscrewing its cap and pulling it out. Wipe it clean with a lint-free cloth, reinsert it fully, then remove it again to check the oil level against the markings. For safety, handle the dipstick carefully and avoid contact with hot engine components.

Historical Development of Dipsticks

The evolution of dipsticks reflects advancements in engine technology and the need for more precise fluid level measurements. Early dipsticks were simple rods, but modern versions, like the Cummins 5561713, incorporate materials and designs that offer greater durability and accuracy. This progression underscores the importance of fluid level monitoring in engine maintenance 4.

Cummins Inc. Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications.

Compatibility with Cummins Engines

The Cummins part number 5561713, a Dipstick, is designed to be compatible with a range of Cummins engines, including the F3.8 CM2350 and F128C models. This dipstick is an essential tool for maintaining these engines, providing a straightforward method to check the oil level and ensure that the engine is operating within its optimal parameters.

For the F3.8 CM2350 engine, the dipstick is engineered to fit seamlessly into the designated oil check port. Its design ensures easy insertion and removal, allowing for quick and accurate oil level assessments. The dipstick’s material and construction are specifically chosen to withstand the high temperatures and pressures typical of engine environments, ensuring durability and reliability.

Similarly, for the F128C engine, the Cummins part number 5561713 dipstick is tailored to fit the oil check port perfectly. Its compatibility with this engine model is critical for maintaining the engine’s performance and longevity. The dipstick’s design facilitates easy access to the oil level, enabling users to perform regular checks and maintain the engine’s health effectively.

Both engines benefit from the use of this dipstick, as it provides a clear and precise indication of the oil level. This is crucial for preventing engine damage due to low oil levels and ensuring that the engine operates smoothly and efficiently.

Conclusion

The Cummins 5561713 Dipstick is a vital component in the maintenance of heavy-duty truck engines. Its robust design, ease of use, and compatibility with various Cummins engines make it an indispensable tool for ensuring optimal engine performance and longevity. Regular use of this dipstick contributes significantly to the overall health and efficiency of the engine.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation, SAE International, 2023.

↩ -

Martynn Randall, Haynes Manual on Diesel Engines, Haynes Publishing, 2015.

↩ -

Meherwan P. Boyce, Gas Turbine Engineering Handbook, Second Edition, Gulf Professional Publishing, 2002.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.