This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

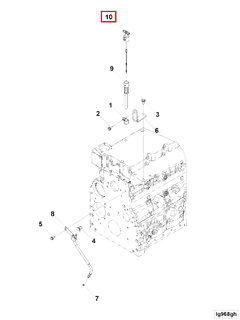

Introduction to Cummins Dipsticks

Cummins, a leading manufacturer of diesel engines and related components, produces a range of parts designed to ensure optimal engine performance. One such essential component is the dipstick, specifically part #4995202. This article provides an in-depth understanding of the Cummins dipstick, its purpose, and its role in maintaining the health of commercial truck engines.

Basic Concepts of a Dipstick

A dipstick is a critical tool used to measure the oil level in an engine. It is a long, thin metal tube with a handle at the top and a marked section at the bottom. When inserted into the engine’s oil pan, the dipstick comes into contact with the oil, allowing for a visual and tactile assessment of the oil level. This simple yet vital tool helps prevent engine damage by ensuring that the oil level remains within the manufacturer’s recommended range 1.

Purpose of Cummins Part #4995202

The Cummins part #4995202 dipstick is specifically designed for use in Cummins engines. Its primary function is to provide accurate readings of the oil level, ensuring that the engine operates smoothly and efficiently. Proper oil levels are crucial for lubricating engine components, reducing friction, and maintaining optimal operating temperatures 2.

Role of the Dipstick in Truck Operations

For engineers, mechanics, and fleet operators, the dipstick is an indispensable tool for routine maintenance. Regularly checking the oil level using the dipstick helps identify potential issues before they escalate into significant problems. Low oil levels can indicate leaks, while unusually high levels might suggest overfilling or oil contamination. By maintaining the correct oil level, operators can extend the lifespan of their engines and ensure reliable performance 3.

Troubleshooting and Maintenance

When using the Cummins part #4995202 dipstick, it is essential to follow a systematic approach to ensure accurate readings and effective maintenance.

- Preparation: Before checking the oil level, ensure the engine is turned off and has cooled down. This prevents inaccurate readings due to thermal expansion of the oil.

- Insertion: Pull out the dipstick, wipe it clean with a lint-free cloth, and reinsert it fully into the oil pan.

- Removal and Reading: Pull the dipstick out again and examine the oil level. The oil should reach the marked “full” line on the dipstick. If the oil level is low, it may be necessary to add more oil.

- Oil Quality: Inspect the oil for any signs of contamination, such as a milky appearance or unusual odor. Contaminated oil may require a change and an investigation into the source of the contamination 4.

Cummins: A Leader in Engine Manufacturing

Cummins is a global leader in the design and manufacture of diesel engines and related components. With a reputation for quality and reliability, Cummins products are trusted by engineers, mechanics, and fleet operators worldwide. The company’s commitment to innovation and excellence ensures that its parts, including the part #4995202 dipstick, meet the highest standards of performance and durability 5.

Importance of Regular Maintenance

Regular maintenance using the Cummins part #4995202 dipstick is crucial for the longevity and efficiency of commercial truck engines. By adhering to the manufacturer’s recommended maintenance schedule and using high-quality Cummins parts, operators can minimize downtime, reduce repair costs, and ensure the reliable operation of their fleets 6.

Conclusion

This article has provided a comprehensive overview of the Cummins part #4995202 dipstick, its purpose, and its role in maintaining commercial truck engines. By understanding and utilizing this essential tool, engineers, mechanics, and fleet operators can ensure the optimal performance and longevity of their engines.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Cummins Inc. Service Manual (5659622). Cummins Inc., 2022.

↩ -

Cummins Inc. Service Manual (5659622). Cummins Inc., 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.