This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

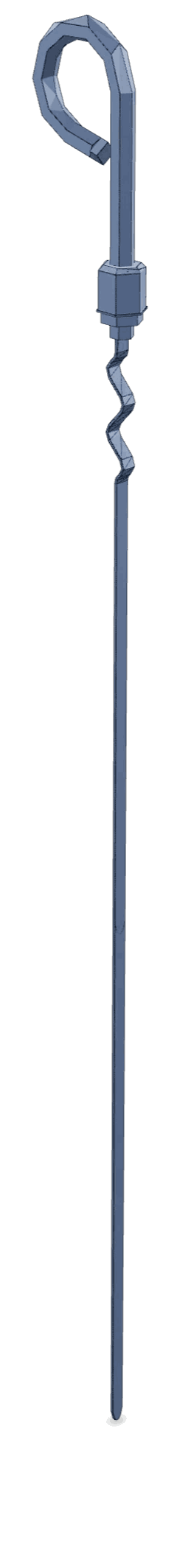

The Cummins 3965170 Dipstick is a specialized component designed for use in heavy-duty trucks. Its primary function is to facilitate the measurement of oil levels within the engine, ensuring that the lubrication system operates effectively. Proper maintenance of oil levels is vital for the longevity and performance of heavy-duty engines, making the dipstick an important tool in routine vehicle maintenance 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in internal combustion engines to measure the level of lubricant, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then removed, the oil level can be read from the markings on the dipstick. This process allows mechanics and operators to ensure that the engine has the appropriate amount of oil for optimal lubrication, cooling, and overall performance 2.

Purpose of the Cummins 3965170 Dipstick

This Cummins part plays a role in the operation of a truck by providing a means to accurately measure the oil level within the engine. Proper lubrication is necessary to reduce friction between moving parts, dissipate heat, and prevent wear and tear. By ensuring that the oil level is correct, the dipstick helps maintain the engine’s efficiency and longevity. It is a straightforward yet effective tool that contributes to the overall maintenance and performance of heavy-duty trucks 3.

Key Features

The Cummins 3965170 Dipstick is characterized by its robust design and high-quality materials. It is typically made from durable metals that can withstand the high temperatures and pressures within an engine. The dipstick features clear, easy-to-read markings for accurate oil level measurement. Its design ensures a snug fit within the engine’s oil tube, preventing oil leaks and ensuring precise readings. Additionally, the handle is ergonomically designed for easy grip and use, even in challenging conditions.

Benefits of Using the Cummins 3965170 Dipstick

Using this Cummins part offers several advantages. Its accurate measurement capabilities ensure that the engine maintains the correct oil level, which is vital for optimal performance and longevity. The dipstick’s durable construction means it can withstand the rigors of heavy-duty use, providing reliable service over time. Additionally, its ease of use makes it a practical tool for both professional mechanics and vehicle operators, facilitating quick and efficient oil level checks.

Troubleshooting and Maintenance

Common issues with dipsticks can include inaccurate readings due to wear or damage, and oil leaks around the dipstick tube. To troubleshoot these problems, it is important to regularly inspect the dipstick for signs of wear or bending, and ensure that it is properly seated in the tube. Maintenance tips include cleaning the dipstick before each use to remove any debris or old oil, and replacing it if any damage is detected. Regular checks and proper care will help ensure the dipstick remains in optimal condition.

Installation and Usage

Installing the Cummins 3965170 Dipstick involves a few straightforward steps. First, ensure the engine is turned off and has had time to cool. Locate the dipstick tube, usually found on the side of the engine. Insert the dipstick fully into the tube until it reaches the bottom, then withdraw it slowly. Check the oil level against the markings on the dipstick. For an accurate reading, wipe the dipstick clean, reinsert it fully, and then check the level again. This process should be performed regularly as part of routine maintenance to ensure the engine is properly lubricated.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has built a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of various applications, ensuring optimal performance and durability 4.

Cummins Engine Dipstick Part 3965170 Compatibility

The Cummins part number 3965170, which is a Dipstick, is designed to fit into specific engine models. This dipstick is integral for checking the oil level and ensuring the engine operates smoothly. Here is a detailed look at the compatibility of this dipstick with various Cummins engines:

6C8.3 Engines

The 6C8.3 engine series benefits from the use of the 3965170 dipstick. This part is engineered to provide accurate oil level readings, ensuring that the engine remains properly lubricated and functions efficiently. The dipstick’s design allows for easy access and clear visibility of the oil level, which is crucial for maintaining engine health.

QSC8.3 Engines

Similarly, the QSC8.3 engine series is compatible with the 3965170 dipstick. This engine model, known for its reliability and performance, requires regular oil level checks to ensure optimal operation. The dipstick’s precision in measuring oil levels helps prevent engine damage due to insufficient lubrication.

CM850 (CM2850) Engines

The CM850 (CM2850) engine series also utilizes the 3965170 dipstick. This engine, favored for its robust construction and efficiency, relies on the dipstick to maintain the correct oil levels. The dipstick’s design ensures that users can easily and accurately check the oil, contributing to the engine’s longevity and performance.

Grouping for Compatibility

When considering the compatibility of the 3965170 dipstick, it is essential to recognize that it is designed to fit into the aforementioned engine models. This part is a critical component for maintaining the health of these engines by ensuring that the oil levels are consistently monitored and maintained. The dipstick’s design and functionality are tailored to provide reliable and accurate readings, which is vital for the proper operation of these engines.

Role of Part 3965170 Dipstick in Engine Systems

The part 3965170 dipstick is an essential component in the monitoring and maintenance of engine systems. It interfaces directly with the oil level gauge to provide accurate readings of the engine’s oil level.

When the dipstick is inserted into the engine’s oil filler tube, it comes into contact with the oil. Upon removal, the oil level can be observed on the dipstick, which is marked with graduated measurements. This data is then transferred to the oil level gauge, allowing for precise monitoring of the oil quantity within the engine.

The dipstick also plays a role in temperature assessment. As it is in constant contact with the engine oil, it can provide a rough estimate of the oil’s temperature based on its feel when touched after removal. This can be an indicator of the engine’s operating temperature and the condition of the oil.

Furthermore, the dipstick allows for the inspection of the oil’s condition. By observing the color and consistency of the oil on the dipstick, one can determine if the oil needs to be changed or if there are any contaminants present that could indicate engine wear or other issues.

In summary, the part 3965170 dipstick is a fundamental component in the routine maintenance and operational assessment of engine systems, working in conjunction with the oil level gauge to ensure the engine operates within optimal conditions.

Conclusion

The Cummins 3965170 Dipstick is a vital component for maintaining the health and performance of heavy-duty truck engines. Its accurate measurement capabilities, durable construction, and ease of use make it an indispensable tool for both professional mechanics and vehicle operators. Regular maintenance and proper use of this dipstick ensure that engines remain properly lubricated, reducing friction, dissipating heat, and preventing wear and tear. By integrating this part into routine maintenance practices, operators can significantly enhance the longevity and efficiency of their engines.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Cummins Inc. Signature™ and ISX Operation and Maintenance Manual. Bulletin Number 3666251.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.