This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

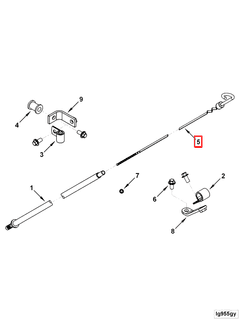

The Cummins 3864249 Dipstick is a specialized component designed for use in heavy-duty trucks. Its primary function is to facilitate the measurement of oil levels within the engine, ensuring that the engine remains properly lubricated. This part is integral to the maintenance and operation of heavy-duty trucks, contributing to the overall efficiency and longevity of the vehicle.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in internal combustion engines to check the level of lubricant, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. The dipstick has graduated markings that allow the user to determine the oil level by observing where the oil reaches on the stick when it is withdrawn. The design and operation of a dipstick are based on the principle of measuring the height of the liquid within a container 1.

Purpose of the Cummins 3864249 Dipstick

The Cummins 3864249 Dipstick plays a role in the operation of a truck by allowing for the accurate measurement of oil levels. Proper lubrication is crucial for the engine’s moving parts, reducing friction and wear. By ensuring that the oil level is within the recommended range, the dipstick helps maintain optimal engine performance and protects against potential damage due to insufficient lubrication 2.

Key Features

The Cummins 3864249 Dipstick incorporates several design elements and materials that enhance its functionality. It is constructed from high-quality steel, providing durability and resistance to corrosion. The dipstick features precise markings for accurate oil level readings and a robust handle for easy insertion and removal. Additionally, it is designed to fit securely within the engine, preventing oil leaks and ensuring reliable measurements.

Benefits

Using the Cummins 3864249 Dipstick offers several advantages. It contributes to improved engine performance by ensuring that the engine is properly lubricated. This can lead to extended engine life, as consistent lubrication reduces wear on critical components. Additionally, the dipstick simplifies maintenance procedures, allowing for quick and accurate oil level checks during routine inspections.

Troubleshooting and Maintenance

Common issues with dipsticks may include inaccurate readings due to bent or damaged sticks, or oil leaks around the dipstick tube. To troubleshoot these problems, inspect the dipstick for any signs of damage and ensure it is properly seated in the tube. Regular maintenance involves cleaning the dipstick before each use to remove any debris or old oil, which can affect the accuracy of the reading.

Installation and Usage

Proper installation of the Cummins 3864249 Dipstick involves ensuring that the engine is off and cool to the touch. The dipstick should be inserted fully into the tube until it reaches the bottom, then withdrawn slowly to check the oil level. It is important to wipe the dipstick clean between readings to obtain an accurate measurement. During routine checks, the oil level should be between the minimum and maximum marks indicated on the dipstick.

Historical Context

The development of dipsticks in the automotive industry has evolved significantly over the years. Early designs were simple and often inaccurate, but advancements in materials and manufacturing techniques have led to more reliable and durable dipsticks. The Cummins 3864249 Dipstick represents the culmination of these advancements, offering precise measurements and enhanced durability for heavy-duty applications 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for producing high-quality components for heavy-duty trucks and other applications. The company is committed to innovation and excellence, ensuring that its products meet the demanding requirements of the automotive industry.

Role of Part 3864249 Dipstick in Engine Systems

The part 3864249 Dipstick is an essential component in the accurate measurement and monitoring of oil levels within an engine system. It interfaces directly with the oil level gauge, providing a mechanical means to assess the quantity of oil present in the engine’s crankcase.

Interaction with Oil Level Gauge

The dipstick works in conjunction with the oil level gauge to offer a visual and sometimes tactile indication of the oil level. When the dipstick is inserted into the engine and then withdrawn, the oil coating on the dipstick is measured against marked levels on the dipstick itself. This measurement is then relayed to the oil level gauge, which may be a simple mechanical indicator or a more sophisticated electronic sensor. The gauge translates the oil level information into a format that is easily readable by the operator, ensuring that the engine maintains optimal lubrication.

Ensuring Proper Lubrication

Maintaining the correct oil level is vital for the engine’s longevity and performance. The dipstick facilitates this by allowing regular checks and timely top-ups of the oil. Inadequate oil levels can lead to increased friction and wear on moving parts, while overfilling can cause foaming and reduced lubrication efficiency. The dipstick, therefore, plays a significant role in preventing both scenarios by providing a straightforward method for oil level assessment.

Integration with Engine Systems

In modern engine systems, the dipstick may also be part of an automated oil monitoring system. Here, the dipstick’s data can be input into the engine’s control unit, which then uses this information to adjust oil flow rates and alert the operator of any anomalies. This integration enhances the engine’s self-monitoring capabilities, contributing to more reliable operation and reduced maintenance intervals.

Role in Maintenance Routines

During routine maintenance, the dipstick is a fundamental tool. It allows mechanics to quickly verify oil levels without dismantling the engine, streamlining the maintenance process. Additionally, the condition of the oil—as indicated by its color and consistency on the dipstick—can provide insights into the engine’s health, informing decisions on whether an oil change is necessary.

Conclusion

In summary, the Cummins 3864249 Dipstick is a pivotal component in the engine system, facilitating accurate oil level measurement, ensuring proper lubrication, and integrating with both manual and automated monitoring systems to enhance engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.