This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

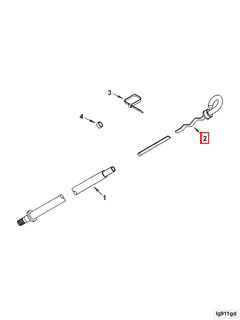

The Cummins 3863456 Dipstick is a component designed for use in commercial trucks, specifically for monitoring engine oil levels. Its role in the maintenance and operation of these vehicles is significant, as it provides a straightforward method for assessing the oil level within the engine, which is vital for ensuring optimal engine performance and longevity 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in engines to measure the level of fluid, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. When removed, the oil level can be read from markings on the dipstick, indicating whether the oil level is within the acceptable range. This process helps in maintaining the correct oil level, which is important for lubrication, cooling, and cleaning within the engine 2.

Purpose of the Cummins 3863456 Dipstick

The Cummins 3863456 Dipstick serves a specific role in the operation and maintenance of a truck’s engine. It allows for the accurate assessment of engine oil levels, ensuring that the engine is neither overfilled nor underfilled. Proper oil levels are important for the engine’s lubrication system, which reduces friction between moving parts, helps in cooling the engine, and removes contaminants 3.

Key Features

The Cummins 3863456 Dipstick is characterized by its robust design and the materials used in its construction. Typically made from high-quality steel, it is resistant to corrosion and wear, ensuring durability in the harsh environment of a commercial truck engine. Its design includes clear markings for easy reading of oil levels and a secure fitting to prevent oil leaks.

Benefits of Using the Cummins 3863456 Dipstick

Utilizing the Cummins 3863456 Dipstick offers several advantages. It provides accurate readings of oil levels, which is important for maintaining engine health. Its ease of use makes it a convenient tool for regular maintenance checks. Additionally, by ensuring proper oil levels, it contributes to the longevity of the engine, potentially reducing the need for repairs and maintenance.

Troubleshooting and Maintenance Suggestions

Common issues with dipsticks can include inaccurate readings due to wear or damage, and oil leaks around the dipstick tube. To address these problems, regular inspection of the dipstick for signs of wear or corrosion is recommended. If inaccuracies are noted, the dipstick may need to be replaced. Ensuring the dipstick is properly seated can help prevent oil leaks.

Installation and Usage Guidelines

Proper installation of the Cummins 3863456 Dipstick involves ensuring it is fully inserted into its tube until it stops, then withdrawn to check the oil level. It’s important to wipe the dipstick clean between readings to get an accurate measurement. Safety precautions include ensuring the engine is off and cool before checking the oil level to avoid burns or injury.

Compatibility and Application

The Cummins 3863456 Dipstick is designed for specific engines and vehicles, with compatibility information available to ensure it fits the intended application. This information helps in selecting the correct dipstick for a particular engine model, ensuring accurate oil level readings and proper engine maintenance.

Historical Context and Evolution

The evolution of dipstick technology reflects advancements in engine design and the need for more accurate and reliable methods of monitoring fluid levels. The Cummins 3863456 Dipstick is part of this evolution, incorporating improvements in design and materials to meet the demands of modern commercial truck engines.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction, providing reliable and efficient power solutions for various applications.

Role of Part 3863456 Dipstick in Engine Systems

The part 3863456 dipstick is an essential component in the accurate measurement and monitoring of oil levels within an engine system. It interfaces directly with the oil level gauge, ensuring that the gauge provides precise readings of the oil quantity present in the engine’s oil reservoir.

When the dipstick is inserted into the oil filler tube, it comes into contact with the oil surface. The oil adheres to the dipstick, and upon removal, the level of oil on the dipstick can be visually assessed against the marked graduations. This direct interaction allows for a straightforward and reliable method of determining the oil level without the need for complex sensors or additional equipment.

The dipstick also plays a role in the overall health and maintenance of the engine. By providing consistent and accurate oil level readings, it enables engineers and mechanics to ensure that the engine maintains optimal lubrication. This, in turn, helps in preventing excessive wear on engine components, reducing the risk of overheating, and ensuring smooth operation.

Furthermore, the dipstick’s design allows it to be easily removed and reinserted, facilitating regular checks and maintenance routines. This simplicity in design and operation makes it a dependable tool in the ongoing care and monitoring of engine systems.

Conclusion

The Cummins 3863456 Dipstick is a vital component in the maintenance and operation of commercial truck engines. Its accurate measurement of oil levels ensures optimal engine performance and longevity. Regular maintenance and proper use of this part contribute significantly to the efficiency and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.