This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

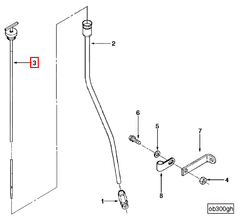

The Cummins 3035227 Dipstick is a component designed for use in heavy-duty trucks. It serves a specific function within the engine’s lubrication system, facilitating the monitoring of oil levels to ensure optimal engine performance and longevity.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in engine maintenance. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then withdrawn, the oil level can be read from the markings on the dipstick, indicating whether the oil is within the appropriate range. This process is fundamental for maintaining the engine’s lubrication system, as proper oil levels are necessary for reducing friction, cooling, and cleaning within the engine 1.

Purpose of the Cummins 3035227 Dipstick

The Cummins 3035227 Dipstick plays a role in the operation and maintenance of a truck’s engine by allowing for the accurate measurement of oil levels. This measurement is crucial for ensuring that the engine remains properly lubricated, which in turn helps in reducing wear and tear on engine components, maintaining engine temperature, and ensuring the engine operates efficiently 2.

Key Features

The Cummins 3035227 Dipstick is characterized by its robust design and the materials used in its construction. It is typically made from high-quality steel, which provides durability and resistance to the high temperatures and pressures within the engine compartment. The dipstick features clear, easy-to-read markings for oil level indication and may include a spring-loaded mechanism to ensure a secure fit within the dipstick tube.

Benefits of Using the Cummins 3035227 Dipstick

Utilizing the Cummins 3035227 Dipstick offers several advantages. Its design ensures accurate oil level readings, which is vital for maintaining engine health. The durability of the materials used means it can withstand the demanding conditions of heavy-duty truck engines. Additionally, its ease of use makes it a practical tool for regular engine maintenance checks 3.

Installation Process

Installing the Cummins 3035227 Dipstick involves a few straightforward steps. First, ensure the engine is turned off and has cooled down to avoid burns. Locate the dipstick tube, usually found near the engine’s top. Remove the old dipstick by pulling it straight out of the tube. Insert the new Cummins 3035227 Dipstick into the tube until it is fully seated. Push it in gently but firmly to ensure it is properly installed. Finally, pull it out to check the oil level, wiping it clean between checks for accurate readings.

Maintenance and Care

To ensure the longevity and accuracy of the Cummins 3035227 Dipstick, regular maintenance is recommended. After each use, wipe the dipstick clean with a lint-free cloth to remove any oil residue. Inspect it for signs of wear or damage, such as bending or corrosion, and replace it if necessary. Keeping the dipstick tube free of debris will also help maintain accurate readings.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings due to a bent dipstick, oil leaks around the dipstick tube, or difficulty inserting the dipstick. If the dipstick is bent, it should be replaced. Oil leaks may indicate a damaged dipstick tube or gasket, requiring inspection and possible repair or replacement. Ensuring the dipstick is fully seated can resolve insertion difficulties.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a long-standing reputation for producing reliable and high-performance components, Cummins continues to lead in the development of advanced engine technologies and parts, including the Cummins 3035227 Dipstick 4.

Cummins Dipstick Part 3035227 Compatibility

The Cummins dipstick part number 3035227 is designed to interface seamlessly with various Cummins engines, ensuring accurate oil level readings and facilitating routine maintenance. This dipstick is engineered to fit into the oil systems of several engine models, providing a reliable means to check oil levels without the need for specialized tools.

V903 Engine Group

The Cummins V903 engine series is one of the many engine families that utilize the 3035227 dipstick. This engine series is known for its robust design and efficiency, making it a popular choice in various industrial applications. The dipstick’s design ensures it can be easily inserted and removed from the oil pan, providing clear visibility of the oil level on the dipstick’s scale.

The compatibility of the 3035227 dipstick with the V903 engine series is a testament to Cummins’ commitment to providing high-quality, interchangeable parts across their engine lineup. This ensures that maintenance personnel can perform oil checks with confidence, knowing that the dipstick is specifically designed to fit and function correctly with the V903 engine.

General Compatibility

Beyond the V903 engine series, the 3035227 dipstick is also compatible with other Cummins engine models that share similar oil system designs. This broad compatibility allows for easier inventory management and reduces the need for multiple dipstick types, streamlining maintenance procedures.

The dipstick’s design incorporates features such as a durable material that can withstand the high temperatures and pressures found in engine oil systems. Additionally, the dipstick’s length and width are precisely engineered to ensure it can reach the oil level in the oil pan accurately, providing a clear and unobstructed view of the oil level.

Role of Part 3035227 Dipstick in Engine Systems

The part 3035227 Dipstick is an essential component in the maintenance and operation of various engine systems. Its primary function is to provide a means of checking the oil level within the engine, ensuring that it remains within the optimal range for efficient performance and longevity.

Integration with Aftercooler Conversion Kit

When an aftercooler conversion kit is installed, the dipstick plays a significant role in the overall system. The aftercooler is designed to reduce the temperature of the air charge before it enters the engine, enhancing combustion efficiency and power output. The dipstick, in this context, ensures that the lubrication system supporting the aftercooler and the engine remains adequately filled. Regular checks using the dipstick help in identifying any potential leaks or excessive oil consumption that might be induced by the modifications brought about by the aftercooler kit.

Arrangement and Oil Fill

In the arrangement of engine components, the dipstick is strategically positioned to offer easy access for oil level checks. This is particularly important during the oil fill process, where precise measurement is necessary to avoid overfilling or underfilling the engine. The dipstick allows mechanics and engineers to verify that the oil fill is correct, thereby maintaining the engine’s lubrication system’s integrity. Proper oil levels are vital for reducing friction, cooling moving parts, and carrying away contaminants, all of which contribute to the engine’s overall performance and durability 5.

Maintenance and Operational Efficiency

Regular use of the dipstick in checking oil levels is a standard practice in maintenance routines. It allows for the early detection of issues such as oil leaks, contamination, or abnormal consumption rates. This proactive approach to maintenance helps in preserving the engine’s operational efficiency, ensuring that all moving parts are adequately lubricated and protected against wear and tear.

Conclusion

The Cummins 3035227 Dipstick is a fundamental component in the maintenance regimen of engine systems, particularly when integrated with enhancements like the aftercooler conversion kit. Its role in facilitating accurate oil level checks contributes significantly to the engine’s performance, reliability, and lifespan.

-

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659690.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.