This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3001051 Dipstick is a component designed for use in commercial trucks, specifically for monitoring engine oil levels. Its role in the maintenance routine of these vehicles is significant, as it allows for accurate and reliable oil level readings, which are vital for ensuring the engine operates within optimal parameters. Proper oil levels contribute to engine longevity and performance, making the dipstick an integral part of routine maintenance checks 1.

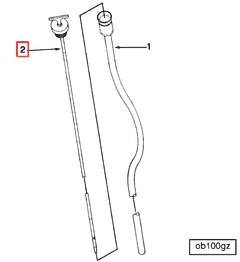

Basic Concepts of a Dipstick

A dipstick is a metal or plastic rod with a handle on one end, used to measure the level of fluid in an engine. It operates on a simple principle: the rod is inserted into the fluid reservoir, and when withdrawn, the level of fluid on the rod indicates the amount of fluid present. Typically, dipsticks have markings that correspond to minimum and maximum fluid levels, allowing for a quick and straightforward assessment 2.

Purpose of the 3001051 Dipstick

The Cummins 3001051 Dipstick serves a specific function in the operation and maintenance of a truck by providing a means to measure oil levels within the engine. Accurate oil level readings are crucial for maintaining engine health, as they ensure that there is sufficient lubrication for all moving parts. This, in turn, helps prevent wear and tear, overheating, and potential engine damage 3.

Key Features

The Cummins 3001051 Dipstick is characterized by its robust design and material composition, which enhance its performance and durability. Crafted from high-quality materials, it is resistant to corrosion and wear, ensuring longevity even in the demanding environment of a commercial truck engine. Its design allows for precise oil level readings, with clear markings for easy interpretation.

Benefits

Utilizing the Cummins 3001051 Dipstick offers several advantages. Its design ensures accuracy in oil level readings, which is crucial for maintaining engine efficiency and longevity. Additionally, its ease of use makes it a practical tool for routine maintenance checks, allowing for quick and reliable assessments of oil levels.

Installation Process

Installing the Cummins 3001051 Dipstick involves a straightforward process. First, ensure the engine is off and has cooled down to avoid burns or injuries. Locate the dipstick tube, usually found near the engine’s top. Remove the old dipstick by pulling it out of the tube. Insert the new 3001051 fully into the tube until it reaches the bottom, then withdraw it to check the oil level. For installation, simply insert the dipstick back into the tube until it is fully seated.

Regular Maintenance Practices

To ensure the Cummins 3001051 Dipstick remains in optimal condition, it is recommended to perform routine checks. This includes regularly verifying the oil level as per the manufacturer’s guidelines and ensuring the dipstick is clean and free from debris. If the dipstick shows signs of wear or damage, it should be replaced to maintain accurate readings.

Troubleshooting Common Issues

Common issues with dipsticks may include inaccurate readings or difficulty in insertion/removal. Inaccurate readings can often be resolved by ensuring the dipstick is fully inserted and withdrawn correctly. If the dipstick is difficult to insert or remove, check for obstructions within the tube or consider lubricating the dipstick slightly to facilitate smoother operation.

Safety Considerations

When using and maintaining the Cummins 3001051 Dipstick, it is important to follow safety guidelines to prevent accidents or injuries. Always ensure the engine is off and has cooled down before checking the oil level. Use caution when handling the dipstick to avoid burns from hot engine components. Additionally, wear appropriate protective gear, such as gloves, to protect your hands during maintenance procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, known for its commitment to quality, innovation, and customer satisfaction. The company’s products are designed to meet the rigorous demands of commercial applications, ensuring reliability and performance in various operating conditions.

Cummins Dipstick Part 3001051 Compatibility

The Cummins dipstick part number 3001051 is designed to be compatible with several engine models, ensuring accurate oil level readings and maintenance. This dipstick is engineered to fit seamlessly with the following engines:

- N14 MECHANICAL

When using the dipstick part 3001051 with the N14 MECHANICAL engine, it is crucial to ensure that the part is correctly aligned and securely fitted to avoid any inaccuracies in oil level readings. Proper installation of this dipstick is essential for maintaining the engine’s health and performance.

Role of Part 3001051 Dipstick in Engine Systems

The part 3001051 dipstick is an essential component in the engine system, working in conjunction with several other elements to ensure optimal engine performance and maintenance.

Interaction with Dipstick and Tube

The dipstick is inserted into the dipstick tube, which is connected to the oil pan. This setup allows for the measurement of the oil level within the engine. The dipstick provides a physical means to check the oil, ensuring that it is within the required range for efficient engine lubrication.

Connection to the Engine Control Module (ECM) and Gauge

Modern engines often integrate the dipstick system with the Engine Control Module (ECM) and the oil level gauge. The ECM may use sensors to monitor the oil level continuously, providing real-time data to the gauge on the dashboard. The dipstick serves as a manual verification tool, allowing mechanics and engineers to cross-check the electronic readings with a physical measurement.

Importance in Oil Level Management

Maintaining the correct oil level is vital for engine health. The dipstick facilitates this by offering a straightforward method to assess the oil level. When the oil level is low, the dipstick indicates this, prompting the need for an oil top-up. Conversely, if the oil level is too high, it can be identified and rectified to prevent potential engine damage.

Enhanced Engine Monitoring

In advanced engine systems, the dipstick’s role extends beyond simple measurement. It is part of a broader monitoring system that includes the oil level sensor and the ECM. This integration allows for more precise engine management, ensuring that oil levels are optimal under various operating conditions.

Practical Application

In practice, the dipstick is used during routine maintenance checks. Engineers and mechanics rely on it to ensure that the engine oil is at the correct level before starting the engine. This simple yet effective tool plays a significant role in preventive maintenance, helping to avoid costly repairs down the line.

Conclusion

The Cummins 3001051 Dipstick is a critical component in the maintenance and operation of commercial truck engines. Its accurate oil level readings contribute to engine longevity and performance, making it an indispensable tool for routine maintenance checks. Proper installation, regular maintenance, and adherence to safety guidelines ensure the effective use of this Cummins part, ultimately supporting the overall efficiency and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.