This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 216476 Dipstick is a specialized tool designed for use in heavy-duty trucks. Its purpose is to facilitate the accurate measurement of engine oil levels, which is a fundamental aspect of maintaining these vehicles. Ensuring the correct oil level is vital for the efficient operation and longevity of the engine 1.

Basic Concepts of a Dipstick

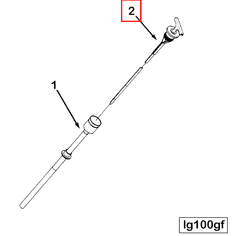

A dipstick is a simple yet essential component in the engine system. It functions by being inserted into the engine’s oil sump, allowing for the measurement of the oil level. The dipstick typically has markings that indicate the minimum and maximum oil levels. This tool plays a role in the engine system by providing a quick and reliable method for checking oil levels, which is important for maintaining engine health and performance 2.

Purpose of the Cummins 216476 Dipstick

The Cummins 216476 Dipstick is specifically designed for heavy-duty truck engines. It aids in maintaining optimal engine performance by allowing for precise oil level measurements. This is particularly important in heavy-duty applications where engine stress and operating conditions can vary significantly 3.

Key Features

The Cummins 216476 Dipstick is characterized by its robust design and the materials used in its construction. It is made from high-quality steel, ensuring durability and resistance to the harsh conditions found in heavy-duty truck engines. The dipstick’s design includes clear and easy-to-read markings for oil level indication, enhancing its functionality.

Benefits of Using the Cummins 216476 Dipstick

Using the Cummins 216476 Dipstick offers several advantages. It provides accurate oil level readings, which are important for maintaining engine efficiency. Its ease of use makes it a practical tool for regular maintenance checks. Additionally, by ensuring the correct oil level, this dipstick contributes to the longevity of the engine.

Installation and Usage

Proper installation and usage of the Cummins 216476 Dipstick involve a few straightforward steps. First, ensure the engine is off and has had time to cool. Insert the dipstick fully into its tube, then withdraw it to check the oil level against the markings. For an accurate reading, wipe the dipstick clean, reinsert it, and then check the level again.

Maintenance and Care

Regular maintenance of the Cummins 216476 Dipstick is important for its longevity and accuracy. This includes cleaning the dipstick after each use to remove any oil residue and inspecting it for any signs of wear or damage. Proper care ensures that the dipstick remains a reliable tool for oil level measurement.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings and physical damage. Inaccurate readings can often be resolved by ensuring the dipstick is properly inserted and read. Physical damage, such as bends or cracks, may require replacement of the dipstick to maintain accurate measurements.

Role in Preventive Maintenance

The Cummins 216476 Dipstick plays a role in a broader preventive maintenance strategy for heavy-duty trucks. Regular oil level checks are important in preventing engine damage. By ensuring the engine has the correct amount of oil, operators can avoid issues such as overheating or insufficient lubrication, which can lead to costly repairs.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the diesel engine and component industry. With a history of innovation and a commitment to quality, Cummins has built a reputation for producing reliable and efficient engine components. Their dipsticks, including the 216476 model, are a testament to their dedication to enhancing engine performance and durability in heavy-duty applications.

Compatibility of Cummins Dipstick Part 216476

The Cummins dipstick part number 216476 is designed to be compatible with a range of Cummins engines. This dipstick is an essential tool for checking the oil level in the engine, ensuring that the engine is properly lubricated and functioning optimally.

Compatible Engines

- K19

- L10 CELECT

- L10 MECHANICAL

- M11 CELECT PLUS

- M11 MECHANICAL

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

- NH/NT 855

- QSM11 CM570

- QSNT14 CM876 N102

- V28

Grouping of Compatible Engines

The Cummins dipstick part 216476 is suitable for various Cummins engines, which can be grouped based on their series and technology:

-

L Series Engines

- L10 CELECT

- L10 MECHANICAL

-

M Series Engines

- M11 CELECT PLUS

- M11 MECHANICAL

-

N Series Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

-

Other Cummins Engines

- K19

- NH/NT 855

- QSM11 CM570

- QSNT14 CM876 N102

- V28

This dipstick is engineered to fit snugly and accurately measure the oil level in these engines, ensuring ease of use and reliability.

Understanding the Role of Part 216476 Dipstick in Engine Systems

The part 216476 dipstick is an essential component in the orchestration of various engine systems, facilitating the seamless operation and maintenance of the engine. Its integration with multiple components ensures the engine’s oil levels are accurately monitored, contributing to the engine’s longevity and performance.

Integration with Oil Systems

The dipstick is meticulously designed to interface with the oil fill and oil pan components. When inserted into the oil pan and dipstick arrangement, it provides a direct measurement of the oil level within the oil pan sub-assembly adapter. This measurement is vital for maintaining optimal oil levels, which are necessary for lubricating moving parts and reducing friction within the engine.

Connection to Gauge Systems

The dipstick also plays a significant role in conjunction with the EBM: Gauge Oil Level system. Upon extraction, the dipstick is often coupled with an oil gauge or oil gauge bayonet, allowing for a visual or mechanical reading of the oil level. This reading is then transmitted through the oil gauge tube to the gauge, providing the operator with real-time data on the engine’s oil status.

Structural Integration

In terms of structural integration, the dipstick is housed within the dipstick and tube assembly, which is, in turn, secured to the cover of the cylinder block (often abbreviated as cyl.block). This securement ensures that the dipstick remains in place during engine operation, offering a stable and reliable method for oil level assessment.

Comprehensive Dipstick Arrangement

The dipstick arrangement is a thoughtfully engineered system that includes the dipstick, its tube, and the surrounding components. This arrangement not only protects the dipstick but also ensures that it functions correctly within the engine’s operating environment. The dipstick’s position within this arrangement allows for easy access during maintenance checks, promoting efficient engine care.

Conclusion

In summary, the Cummins 216476 Dipstick is a pivotal element in the engine’s oil management system, working in harmony with various components to ensure the engine operates within its designed parameters. Its role extends beyond simple measurement, contributing to the overall health and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.