This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

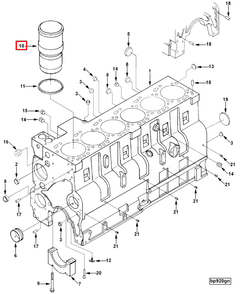

The Cummins 3919937 Cylinder Liner is a component designed for use in heavy-duty truck engines. It plays a role in the operation of these engines by providing a durable and smooth surface for the piston to travel within the cylinder. Cylinder liners are integral to the internal combustion engine, contributing to its efficiency, performance, and longevity. This article provides an in-depth look at the 3919937, exploring its function, features, and benefits within the context of heavy-duty truck engines.

Basic Concepts of Cylinder Liners

A cylinder liner, also known as a cylinder sleeve, is a replaceable component that forms the inner surface of an engine’s cylinder. Its primary function is to facilitate the smooth movement of the piston and to withstand the high pressures and temperatures generated during combustion. Cylinder liners interact closely with piston rings, coolant passages, and lubrication systems to ensure optimal engine operation. Materials commonly used for cylinder liners include cast iron, steel, and aluminum, each offering distinct properties such as hardness, thermal conductivity, and wear resistance 1.

Purpose of the Cummins 3919937 Cylinder Liner

The Cummins 3919937 is specifically engineered to enhance the performance, durability, and efficiency of truck engines. By providing a precise and wear-resistant surface for the piston, it contributes to reduced friction and wear, leading to improved engine longevity. Additionally, the design of this cylinder liner supports efficient heat dissipation and maintains consistent engine performance under varying load conditions 2.

Key Features

The Cummins 3919937 boasts several key features that set it apart from other cylinder liners. Its design incorporates advanced manufacturing processes to ensure precision fitment and durability. Unique characteristics may include specialized coatings for enhanced wear resistance, optimized wall thickness for improved thermal efficiency, and compatibility with high-performance engine configurations.

Benefits

Utilizing the Cummins 3919937 offers several advantages. These include improved engine longevity due to reduced wear and friction, enhanced performance through precise engineering, and potential cost savings over the engine’s lifespan due to its durability and efficiency. The liner’s design also contributes to better fuel economy and reduced emissions, aligning with modern environmental standards 3.

Installation and Compatibility

Proper installation of the Cummins 3919937 is crucial for ensuring its effectiveness and the overall health of the engine. Installation guidelines may include specific torque settings, the use of appropriate gaskets, and ensuring the liner is properly seated within the cylinder bore. Compatibility information is vital for selecting the correct cylinder liner for a given engine model, ensuring optimal performance and longevity.

Maintenance and Troubleshooting

Routine maintenance practices are essential for preserving the performance and longevity of the Cummins 3919937. This may involve regular inspections for wear, proper lubrication, and addressing any signs of damage promptly. Common issues with cylinder liners can include glazing, scoring, or excessive wear, each requiring specific troubleshooting steps to resolve.

Performance and Efficiency

The Cummins 3919937 plays a significant role in the overall performance and efficiency of the engine. By providing a smooth and durable surface for the piston, it contributes to reduced friction, improved fuel economy, and consistent power output. Additionally, its design supports efficient heat management, contributing to lower emissions and enhanced engine reliability.

Compatibility with Cummins Engines

The 3919937 is designed to fit seamlessly within a range of Cummins engines, ensuring optimal performance and longevity. This part is integral to the engine’s structure, providing a smooth surface for the piston to move against, which is crucial for the engine’s efficiency and durability.

6C8.3 and C8.3 G Engines

The 3919937 is compatible with the 6C8.3 and C8.3 G engines. These engines are known for their robust design and are often used in heavy-duty applications. The liner ensures that the piston rings can create a tight seal, minimizing oil consumption and maximizing power output.

C GAS PLUS CM556 and G8.3 Engines

For the C GAS PLUS CM556 and G8.3 engines, the 3919937 is engineered to fit precisely, maintaining the engine’s integrity and performance. These engines are typically used in a variety of applications, from agricultural to industrial uses, and the liner plays a role in their operation.

ISC CM554 Engine

The ISC CM554 engine also benefits from the 3919937. This engine is known for its reliability and efficiency, and the liner is designed to withstand the high pressures and temperatures it operates under. The fitment of this part ensures that the engine can perform at its best, providing consistent power and longevity.

Compatibility and Installation

When installing the 3919937, it is essential to follow the manufacturer’s guidelines to ensure a proper fit. This includes checking for any pre-existing damage or wear in the engine block and ensuring that the liner is installed at the correct angle and depth. Proper installation is key to maintaining the engine’s performance and preventing potential issues down the line.

Role of the 3919937 in Engine Systems

The 3919937 is an essential component in various engine systems, working in conjunction with several other parts to ensure optimal engine performance.

- 6C Cylinder Kit: The Cylinder Liner provides a smooth surface for the piston to travel within, reducing friction and wear. This is vital for maintaining the efficiency and longevity of the engine.

- Block: The Cylinder Liner enhances the structural integrity of the engine by offering a precise fit within the cylinder bores. This ensures consistent combustion chamber volumes and improved engine reliability.

- Cylinder Block: The Cylinder Liner allows for easier replacement and maintenance. This is particularly beneficial in high-mileage engines where cylinder wear is a common issue.

- Crankshaft and Bearings Systems: The Cylinder Liner ensures that the piston’s movement is uniform and smooth. This reduces the stress on the crankshaft and main bearings, leading to a more stable engine operation.

- Cylinder 6Cart Kit or Cylinder 6CTA: The Cylinder Liner contributes to the overall precision and performance of the engine. It allows for better heat dissipation and improved combustion efficiency.

- Cylinder Kit or 6CTAA Kit: The Cylinder Liner ensures that the engine can withstand higher pressures and temperatures, which is essential for performance-oriented applications.

- Ford Dealer Applications: The Cylinder Liner is often included in Liner Assembly Cylinder and Liner Kit packages to provide a reliable and durable solution for engine rebuilds and overhauls.

- Long Block or Short Block Assembly: The Cylinder Liner is a fundamental component that ensures the engine’s internal components operate within specified tolerances. This is important for both new engine builds and comprehensive engine overhauls.

- Overhaul Kit or Parts Distribution Center Kit: The Cylinder Liner is a key component that facilitates the restoration of an engine to its original performance standards. It allows mechanics to address wear and tear effectively, ensuring the engine operates smoothly post-overhaul.

Conclusion

The Cummins 3919937 Cylinder Liner is a critical component in the maintenance and performance of heavy-duty truck engines. Its design and features contribute to reduced friction, improved fuel economy, and consistent power output. Proper installation, maintenance, and understanding of its role within various engine systems are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.