This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

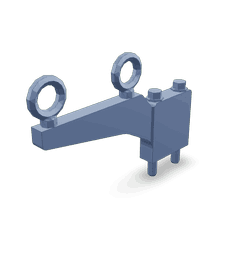

The 3164394 Cylinder Head Lifting Fixture is a specialized tool designed by Cummins for the maintenance and repair of heavy-duty truck engines. This Cummins part is integral to the process of safely and efficiently removing and installing cylinder heads, which are essential components in the engine’s operation. Its design and functionality are tailored to meet the demanding requirements of heavy-duty engine maintenance, ensuring both the safety of the technician and the integrity of the engine components.

Purpose and Functionality

The Cylinder Head Lifting Fixture serves a pivotal role in the maintenance process by facilitating the safe removal and installation of cylinder heads in truck engines. This fixture is engineered to provide a stable and secure platform for handling cylinder heads, which are heavy and complex components. By using this fixture, mechanics can perform these tasks with greater precision and reduced risk of injury or damage to the engine. It contributes to the overall engine maintenance process by ensuring that cylinder heads are handled correctly, which is vital for the engine’s performance and longevity 1.

Key Features

The 3164394 is constructed with durability and performance in mind. It is made from high-strength materials that can withstand the rigors of heavy-duty engine maintenance. The design includes features such as reinforced lifting points and a stable base, which enhance its structural integrity. Additionally, the fixture may incorporate unique design elements like adjustable components or ergonomic handles to improve its functionality and ease of use 2.

Benefits

Utilizing the Cylinder Head Lifting Fixture offers several advantages. It enhances safety during the manipulation of cylinder heads by providing a secure grip and stable platform. This reduces the physical strain on mechanics, allowing for more comfortable and efficient work. Furthermore, the fixture improves the precision of engine repairs by ensuring that cylinder heads are aligned correctly during installation, which is crucial for the engine’s optimal performance 3.

Installation and Usage Guidelines

To install and use the Cylinder Head Lifting Fixture effectively, follow these steps: First, ensure the engine is cool and the cylinder head is detached from the engine block. Position the fixture under the cylinder head, aligning it with the lifting points. Securely attach the fixture to the cylinder head using the provided hardware. Once attached, lift the cylinder head slowly and carefully, ensuring stability throughout the process. For installation, reverse the steps, ensuring the cylinder head is properly aligned with the engine block before securing it in place. Always refer to the manufacturer’s instructions for specific guidelines and safety precautions.

Maintenance and Troubleshooting

Routine maintenance of the Cylinder Head Lifting Fixture is vital for its longevity and optimal performance. Regularly inspect the fixture for signs of wear or damage, particularly on the lifting points and structural components. Clean the fixture after each use to remove any debris or contaminants that could affect its performance. For troubleshooting common issues, such as difficulty in securing the fixture to the cylinder head, ensure that all hardware is tightened properly and that the fixture is correctly aligned with the lifting points. If problems persist, consult the manufacturer’s guidelines or contact technical support for assistance.

Safety Considerations

When using the Cylinder Head Lifting Fixture, it is imperative to observe safety protocols and precautions. Ensure that the fixture is used within its specified weight and load limits. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Proper training on the use of the fixture is crucial, as is adherence to all safety guidelines provided by the manufacturer. This ensures not only the safety of the technician but also the integrity of the engine components being worked on.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engine components and systems, all designed to meet the highest standards of performance and reliability. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that each product, including the Cylinder Head Lifting Fixture, meets the demanding requirements of its customers 4.

Conclusion

The 3164394 Cylinder Head Lifting Fixture is a vital tool in the maintenance and repair of heavy-duty truck engines, offering enhanced safety, precision, and efficiency. Its robust design and features make it an indispensable asset for mechanics working on Cummins engines, ensuring both the safety of the technician and the integrity of the engine components.

-

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Cummins Inc. Owners Manual for QSK78 CM2350 K126. Bulletin Number 5504264.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.