This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

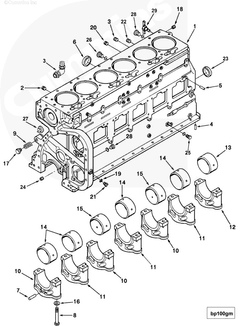

The Cummins 3081284 Cylinder Block is a critical component in heavy-duty truck engines, contributing to efficient engine performance. This part is integral to the engine’s operation, ensuring that the engine runs smoothly and effectively under demanding conditions.

Basic Concepts of a Cylinder Block

A cylinder block, often simply called a block, is the main structure of an engine. It houses the cylinders, where combustion occurs, and provides a foundation for other engine components. The block facilitates the movement of pistons, which are connected to the crankshaft, and interacts with the cylinder head, cooling system, and lubrication system to maintain engine function 1.

Purpose of the Cummins 3081284 Cylinder Block

The Cummins 3081284 Cylinder Block plays a specific role in the operation of heavy-duty trucks. It supports the combustion process by providing a sturdy housing for the cylinders and pistons. This block contributes to engine efficiency by ensuring precise alignment and movement of engine components, and it enhances durability through its robust construction 2.

Key Features

The Cummins 3081284 Cylinder Block is characterized by several key features that enhance its performance. It is made from high-quality cast iron, which provides excellent strength and heat dissipation. The design includes precise machining for optimal fit and function, and it features integrated cooling passages to manage engine temperature effectively 3.

Benefits

The Cummins 3081284 Cylinder Block offers several benefits. It improves engine performance by ensuring smooth operation of the pistons and cylinders. Its durable construction contributes to the longevity of the engine, and its reliable design enhances the overall reliability of the heavy-duty truck.

Installation Process

Installing the Cummins 3081284 Cylinder Block requires careful preparation and the use of appropriate tools. The process involves aligning the block with the engine’s mounting points, securing it in place, and connecting it to the cylinder head and other components. Proper torque specifications must be followed to ensure a secure fit.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3081284 Cylinder Block, regular maintenance is necessary. This includes inspecting the block for signs of wear or damage, cleaning cooling passages to prevent blockages, and ensuring that all connections are secure and free from leaks.

Troubleshooting Common Issues

Common issues with the Cummins 3081284 Cylinder Block may include cracks, warping, or coolant leaks. Troubleshooting these issues involves a thorough inspection of the block, checking for proper alignment and fit, and addressing any signs of damage or wear promptly to prevent further complications.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a history of innovation and quality, providing reliable engine components and solutions for a wide range of applications.

Role of Part 3081284 Cylinder Block in Engine Systems

The cylinder block, identified as part 3081284, serves as the foundational structure within an engine system, integrating with various components to facilitate efficient operation. This component houses the cylinders, where the pistons move up and down, driven by the combustion process.

Integration with Base Parts

-

Crankshaft: The cylinder block interfaces directly with the crankshaft, which converts the linear motion of the pistons into rotational motion. Precision alignment between the cylinder block and crankshaft is essential for smooth engine operation.

-

Pistons and Connecting Rods: Within the cylinder block, pistons are housed in cylinders and are connected to the crankshaft via connecting rods. This assembly allows for the transfer of force generated from combustion to the crankshaft.

-

Cylinder Head: The cylinder block mates with the cylinder head, which covers the cylinders and contains the valves. Proper sealing between these components is vital to maintain compression and prevent leaks.

-

Main Bearings: These bearings are positioned within the cylinder block to support the crankshaft. They reduce friction and wear, ensuring the crankshaft operates smoothly.

-

Oil Pan: The cylinder block is typically bolted to the oil pan, which stores the engine oil. This connection ensures a sealed environment for the lubrication system.

-

Water Jacket: Integrated within the cylinder block, the water jacket circulates coolant to manage engine temperature. Efficient heat dissipation is key to preventing overheating and maintaining engine performance.

-

Intake and Exhaust Manifolds: These manifolds connect to the cylinder block to route air and exhaust gases to and from the cylinders. Proper sealing and alignment are necessary to optimize airflow and combustion efficiency.

-

Flywheel/Flexplate: Attached to the rear of the crankshaft, the flywheel (in manual transmissions) or flexplate (in automatic transmissions) interfaces with the cylinder block. This component plays a role in storing rotational energy and smoothing out engine operation.

-

Timing Chain/Belt Components: The cylinder block houses the timing chain or belt system, which synchronizes the rotation of the crankshaft and camshaft. Accurate timing is essential for valve operation and overall engine performance.

-

Mounting Brackets: Various brackets and supports are attached to the cylinder block to secure other engine components, such as the alternator, power steering pump, and air conditioning compressor. These attachments ensure the stability and proper functioning of auxiliary systems.

Conclusion

In summary, the Cummins 3081284 Cylinder Block is integral to the engine’s structural integrity and operational efficiency, interacting with a multitude of components to deliver power and performance. Regular maintenance and proper installation are key to ensuring the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.