This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

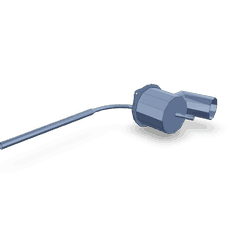

The Cummins 4967279 Hand Hole Cover is a component designed for use in heavy-duty trucks. It serves a specific function in the maintenance and operation of these vehicles, providing necessary access to engine components for inspection and maintenance purposes 1.

Purpose and Function

The Hand Hole Cover plays a role in facilitating access to the engine’s internal components. This access is vital for routine maintenance checks, such as oil level inspections, and for more detailed inspections that may be required during servicing. By providing a secure yet removable cover over the hand hole, it ensures that the engine compartment remains clean and protected from contaminants while still allowing for easy access when needed 2.

Design and Construction

This Cummins part is constructed from materials chosen for their durability and resistance to the harsh conditions often encountered in heavy-duty truck operations. The design incorporates features that ensure a snug fit over the hand hole, minimizing the risk of leaks or the ingress of dirt and debris. The materials used are resistant to corrosion and wear, ensuring the cover remains effective over the long term 3.

Key Features

Several features contribute to the effectiveness of the 4967279. Its design ensures a precise fit, which is crucial for maintaining the integrity of the engine compartment. The finish is smooth yet durable, resisting the wear and tear associated with frequent use. Unique design elements may include reinforced edges for added strength or specific shapes that facilitate easy removal and reinstallation.

Installation Process

Installing the Hand Hole Cover involves several steps to ensure a secure fit. First, the area around the hand hole should be cleaned to remove any dirt or debris. The cover is then positioned over the hand hole and secured in place, following the manufacturer’s instructions for any fastening mechanisms. Tools required may include a socket wrench for tightening fasteners. It’s important to follow best practices during installation to ensure the cover is properly seated and secured.

Maintenance and Care

Regular maintenance of the Hand Hole Cover is important to prolong its lifespan and ensure reliable performance. This includes checking for signs of wear or damage, cleaning the cover as part of routine engine maintenance, and ensuring it is properly secured after each use. Addressing any issues promptly can prevent more significant problems down the line.

Common Issues and Troubleshooting

Common issues with Hand Hole Covers may include wear around the edges, difficulty in removal or reinstallation, or signs of corrosion. These issues can often be addressed by inspecting the cover for damage, ensuring it is correctly installed, or applying a protective coating to prevent corrosion. In cases where the cover is damaged beyond repair, replacement may be necessary.

Benefits of Using Cummins Hand Hole Covers

Choosing Cummins Hand Hole Covers offers several advantages. These covers are engineered to meet the high standards of quality and reliability associated with Cummins products. They are designed specifically for compatibility with Cummins engines, ensuring a perfect fit and function. The use of Cummins parts can contribute to the overall efficiency and longevity of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s product range includes engines and components for on-highway, off-highway, and power generation applications, demonstrating a broad expertise in the automotive and heavy-duty truck industries.

Application in Cummins Engines

QSK60 Engine Series

The QSK60 engine series, known for its robust performance and reliability, incorporates the 4967279 in its design. This part is strategically placed to facilitate easy access to internal components, enabling efficient maintenance procedures. The QSK60 engines are widely used in various industrial applications, including power generation and marine, where regular maintenance is crucial for sustained operation.

CM850 Engine Series

In the CM850 engine series, the 4967279 plays a vital role in ensuring that maintenance personnel can access specific areas of the engine safely. The CM850 engines are designed for heavy-duty applications, and the inclusion of this part helps in maintaining the engine’s operational efficiency by allowing for straightforward access during routine inspections and repairs.

MCRS Engine Series

The MCRS engine series, another line of Cummins engines, also utilizes the 4967279. This part is integral to the engine’s design, providing necessary access points that are essential for the engine’s upkeep. The MCRS engines are known for their versatility and are used in various sectors, including construction and agriculture, where reliable maintenance access is paramount.

By incorporating the 4967279, Cummins ensures that technicians can perform maintenance tasks with ease and safety, thereby contributing to the longevity and reliability of these engines across different applications.

Understanding the Integration of Part 4967279 Hand Hole Cover in Engine Systems

The 4967279 is an essential component in the assembly and maintenance of various engine systems. Its primary function is to provide secure access points for engineers and mechanics during routine inspections, repairs, and maintenance procedures.

Role in Engine Assembly

During the assembly phase of an engine, the Hand Hole Cover is meticulously fitted over designated access points. These points are strategically located to allow hands-on manipulation of internal components without dismantling the entire engine. The cover ensures that these access points are protected from contaminants, such as dirt, debris, and moisture, which could otherwise compromise engine performance and longevity.

Facilitation of Maintenance Procedures

In maintenance scenarios, the Hand Hole Cover plays a significant role. It is temporarily removed to grant access to internal components for inspection, lubrication, or replacement. The design of the cover allows for easy removal and reinstallation, minimizing downtime during maintenance operations. This is particularly important in high-performance engines where every minute of downtime can impact overall efficiency and output.

Interaction with Other Components

The Hand Hole Cover interacts with several other engine components to ensure seamless operation. For instance, it is often positioned near gaskets, which provide a seal between the cover and the engine block. This seal is vital for maintaining the engine’s integrity, preventing leaks, and ensuring that the internal pressure remains consistent.

Additionally, the cover may be located near sensors and wiring harnesses. Its presence ensures that these sensitive components are shielded from physical damage and environmental factors, thereby enhancing the reliability and accuracy of engine diagnostics and performance monitoring.

Enhancement of Safety and Efficiency

By providing a secure yet accessible point for hand entry, the Hand Hole Cover enhances both safety and efficiency. Mechanics can perform necessary adjustments and inspections with greater ease and precision, reducing the risk of injury and ensuring that maintenance tasks are completed accurately and efficiently.

Conclusion

In summary, the 4967279 Hand Hole Cover is a pivotal component in the engine systems, facilitating easier access for maintenance while protecting internal components from external contaminants and damage. Its integration with other engine components ensures that the engine operates at optimal efficiency, with minimal risk of downtime or performance degradation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.