This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Corrosion Resistor Head, part number 3819767, manufactured by Cummins, is a component designed to enhance the durability and efficiency of commercial truck engines. Cummins, a well-established name in the automotive industry, is known for its commitment to innovation and quality. This part is significant in commercial truck operations as it helps maintain engine integrity and performance under various operating conditions.

Basic Concepts

A Corrosion Resistor Head is a component used in a truck’s engine system to prevent corrosion. Its primary function is to protect engine components from the damaging effects of corrosive elements, which can be present in the engine’s operating environment. The head operates by creating a barrier that resists the penetration of corrosive agents, thereby preserving the structural integrity of the engine components 1.

Purpose of the Corrosion Resistor Head

The Corrosion Resistor Head plays a role in the operation of a truck by protecting engine components from corrosive elements. This protection is vital for maintaining the engine’s efficiency and longevity. By preventing corrosion, the head helps ensure that the engine operates smoothly and reliably, reducing the likelihood of unexpected failures and downtime 2.

Key Features

The Corrosion Resistor Head is characterized by several key features that enhance its performance and durability. These include a material composition designed to resist corrosion, a design that integrates seamlessly with the engine system, and unique attributes that provide superior protection against corrosive elements. These features contribute to the head’s effectiveness in protecting engine components 3.

Benefits

Using the Corrosion Resistor Head in truck engines offers several advantages. These include improved engine longevity, as the head helps prevent corrosion that can lead to engine wear and failure. Additionally, the head reduces maintenance needs by protecting engine components from corrosive damage, leading to lower overall maintenance costs. Enhanced overall performance is another benefit, as a well-protected engine operates more efficiently and reliably.

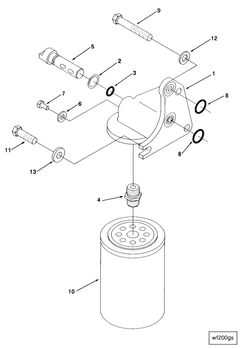

Installation Process

Proper installation of the Corrosion Resistor Head is crucial for ensuring optimal performance. The installation process involves several steps, including preparing the engine for installation, positioning the head correctly, and securing it in place. Tools and equipment required for installation may vary, but typically include standard hand tools. Following best practices during installation helps ensure that the head functions as intended and provides the expected level of protection against corrosion.

Troubleshooting and Maintenance

Common issues that may arise with the Corrosion Resistor Head include signs of corrosion or damage to the head itself. Diagnosing problems involves inspecting the head for any visible signs of wear or corrosion and assessing its fit and function within the engine system. Maintenance tips to prolong the head’s lifespan include regular inspections for signs of corrosion, cleaning the head as needed, and replacing it if significant wear or damage is detected. Consistent performance can be ensured by adhering to these maintenance practices.

Environmental Impact

The use of a Corrosion Resistor Head contributes to reducing environmental harm by minimizing the need for frequent replacements and lowering the overall carbon footprint of truck operations. By protecting engine components from corrosion, the head helps extend the life of the engine, reducing the frequency of part replacements and the associated environmental impact. This contributes to more sustainable truck operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and quality in the automotive industry. The company’s product range includes engines and components for various applications, demonstrating its expertise and dedication to providing reliable and efficient solutions for its customers.

Corrosion Resistor Head (Part 3819767) Compatibility with Cummins Engines

The Corrosion Resistor Head, part number 3819767, is designed to enhance the durability and longevity of various Cummins engines by protecting against corrosion. This part is engineered to fit seamlessly into a range of Cummins engine models, ensuring optimal performance and reliability.

ISM Series Engines

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, are designed for heavy-duty applications. The Corrosion Resistor Head is compatible with these engines, providing protection against the corrosive elements that can degrade engine components over time. This compatibility ensures that the ISM series engines maintain their performance and reliability in demanding environments.

L10 Series Engines

The L10 series engines, which include the L10 CELECT, L10 GAS, and L10 MECHANICAL, benefit from the Corrosion Resistor Head as well. This part is crucial for these engines, as it helps to prevent corrosion that can lead to costly repairs and downtime. The L10 series engines are known for their versatility and efficiency, and the Corrosion Resistor Head ensures that these engines continue to operate smoothly and reliably.

M11 Series Engines

The M11 series engines, including the M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL, are another group of engines that are compatible with the Corrosion Resistor Head. These engines are designed for a range of applications, from on-highway to off-highway use. The Corrosion Resistor Head is essential for these engines, as it helps to protect against corrosion and maintain the integrity of the engine components.

QSM11 Series Engines

The QSM11 series engines, which include the QSM11 CM570 and QSM11 CM876, also benefit from the Corrosion Resistor Head. These engines are known for their high performance and efficiency, and the Corrosion Resistor Head ensures that they remain in top condition by preventing corrosion. This compatibility is crucial for maintaining the reliability and performance of the QSM11 series engines.

By ensuring that the Corrosion Resistor Head is compatible with a wide range of Cummins engines, this part plays a vital role in protecting these engines from corrosion and extending their service life.

Understanding the Role of Part 3819767 Corrosion Resistor Head in Engine Systems

The Corrosion Resistor Head is an essential component in various engine systems, particularly those exposed to harsh environments or corrosive substances. This component is designed to enhance the durability and efficiency of the engine by mitigating the adverse effects of corrosion.

Integration with Engine Components

-

Fuel Injection Systems: In fuel injection systems, the Corrosion Resistor Head ensures that the fuel injectors remain free from corrosion. This is particularly important in diesel engines where the fuel can contain impurities that lead to corrosion. The resistor head helps maintain the precision of fuel delivery, ensuring optimal combustion and performance.

-

Exhaust Systems: When integrated into exhaust systems, the Corrosion Resistor Head protects components such as the exhaust manifold and catalytic converter from the corrosive effects of exhaust gases. This protection is vital for maintaining the efficiency of the exhaust system and reducing emissions.

-

Cooling Systems: In cooling systems, the Corrosion Resistor Head is used to safeguard radiator components and hoses from the corrosive properties of coolant. This ensures that the cooling system operates efficiently, preventing overheating and extending the lifespan of the engine.

-

Electrical Systems: For electrical systems within the engine, the Corrosion Resistor Head is employed to protect wiring and connectors from environmental corrosion. This is especially important in marine or industrial applications where salt and other corrosive agents are prevalent.

-

Turbochargers: In turbocharged engines, the Corrosion Resistor Head is used to protect the turbocharger’s internal components from the corrosive effects of exhaust gases and oil. This protection is essential for maintaining the turbocharger’s efficiency and longevity.

-

Sensors and Actuators: Many sensors and actuators within the engine are susceptible to corrosion. The Corrosion Resistor Head is utilized to coat these components, ensuring they provide accurate readings and reliable performance over time.

By incorporating the Corrosion Resistor Head into these engine systems, engineers and mechanics can significantly enhance the reliability and performance of the engine, particularly in corrosive environments. This component plays a key role in maintaining the integrity of various engine parts, ensuring they function correctly and last longer.

Conclusion

The Corrosion Resistor Head, part number 3819767, is a critical component in the maintenance and efficiency of commercial truck engines. By protecting engine components from corrosion, this part ensures that engines operate reliably and efficiently, reducing maintenance needs and extending engine life. Its compatibility with a wide range of Cummins engines underscores its importance in the automotive industry. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for maximizing the benefits of this Cummins part.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023.

↩ -

Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, Haoran Hu, Simon J Baseley and Xubin Song, SAE International, 2021.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.