This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

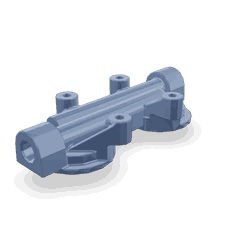

The Corrosion Resistor Head 215617, a component designed by Cummins for heavy-duty truck systems, is integral to the operation and longevity of these vehicles. Cummins is known for its commitment to quality and innovation in manufacturing truck components, ensuring that each part, including this Corrosion Resistor Head, meets high standards of performance and durability.

Basic Concepts of Corrosion Resistor Head

A Corrosion Resistor Head is designed to resist the corrosive effects that can occur in a truck’s system due to environmental factors. The 215617 functions by protecting critical components within the truck’s system from corrosion, ensuring the longevity and efficiency of the vehicle. Its design incorporates materials and construction techniques chosen for their resistance to corrosion, making it an effective barrier against moisture, chemicals, and other corrosive agents.

Role and Function in Truck Operation

The Corrosion Resistor Head 215617 safeguards the integrity of the engine and other critical systems from corrosion. It interacts with various components within the truck’s system, providing a protective layer that prevents corrosion. This protection is vital for maintaining the efficiency and reliability of the truck, as corrosion can lead to component failure and increased maintenance needs.

Key Features

The Corrosion Resistor Head 215617 is characterized by several key features that enhance its performance and durability. These include the use of high-quality materials resistant to corrosion, a design that ensures optimal coverage and protection of critical components, and a protective coating that enhances its resistance to environmental factors. These features work together to provide superior protection against corrosion, ensuring the longevity and efficiency of the truck.

Benefits of Using Corrosion Resistor Head 215617

Incorporating the Corrosion Resistor Head 215617 into truck systems offers several advantages. These include improved longevity of the vehicle due to enhanced protection against corrosion, enhanced performance as critical components are safeguarded from damage, and reduced maintenance needs as the risk of corrosion-related failures is minimized. These benefits contribute to the overall efficiency and reliability of the truck, making the Corrosion Resistor Head 215617 a valuable component for heavy-duty truck systems.

Installation Considerations

Proper installation of the Corrosion Resistor Head 215617 is crucial for ensuring its effectiveness. Guidelines for installation include ensuring compatibility with the specific truck model and system, following manufacturer recommendations for placement and securing the component, and verifying that all connections are secure and properly sealed to prevent exposure to corrosive elements. These considerations help ensure that the Corrosion Resistor Head 215617 functions as intended, providing optimal protection against corrosion.

Maintenance and Troubleshooting

Maintaining the Corrosion Resistor Head 215617 is important for ensuring its continued effectiveness. Regular inspection practices, such as checking for signs of wear or damage, and cleaning procedures to remove any buildup that could compromise its protective properties, are recommended. Troubleshooting common issues, such as identifying and addressing any breaches in the protective layer, can help maintain the integrity of the component and the systems it protects.

Environmental and Operational Factors

Environmental conditions and operational factors can affect the performance and longevity of the Corrosion Resistor Head 215617. Exposure to moisture, chemicals, and other corrosive agents can compromise its protective properties, while operational factors such as temperature fluctuations and mechanical stress can also impact its effectiveness. Mitigating these effects involves regular maintenance, proper installation, and considering environmental factors when operating the vehicle.

Cummins: Manufacturer Overview

Cummins, the manufacturer of the Corrosion Resistor Head 215617, has a long-standing reputation in the automotive industry for quality and innovation. With a history of producing reliable and durable components for heavy-duty trucks, Cummins is committed to advancing the technology and materials used in its products. This commitment ensures that components like the Corrosion Resistor Head 215617 not only meet but exceed industry standards for performance, durability, and protection against environmental factors.

Compatibility of Cummins Corrosion Resistant Head 215617

The Cummins Corrosion Resistant Head 215617 is designed to fit a variety of Cummins engines, providing enhanced durability and resistance to corrosion. This part is particularly useful in environments where engines are exposed to harsh conditions that could otherwise lead to accelerated wear and tear.

Compatible Engines

QSK19 Series:

- QSK19 CM2350 K105

- QSK19 CM2150 MCRS

QSK38 Series:

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

QSK50 Series:

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

Other Models:

- K19

- K38

- K50

- V28

The Corrosion Resistant Head 215617 is engineered to ensure a precise fit and optimal performance across these engine models, making it a versatile choice for maintenance and upgrades.

Understanding the Integration of Part 215617 Corrosion Resistor Head in Engine Systems

The part 215617 Corrosion Resistor Head is an essential component in the orchestration of various engine systems, ensuring optimal performance and longevity. Its role is multifaceted, interfacing with several key components to maintain the integrity and efficiency of the engine’s cooling and corrosion protection mechanisms.

Interaction with Base Parts and Manifold Wet

The corrosion resistor head, specifically part 215617, is designed to work in conjunction with base parts and the manifold wet system. It facilitates the even distribution of coolant throughout the engine, which is vital for maintaining consistent temperatures across all engine components. This uniform cooling is paramount in preventing hotspots that could lead to material fatigue and failure.

Synergy with Corrosion Diesel Coolant Additive Resistor and Corrosion Resistor Arrangement

When integrated with the corrosion diesel coolant additive resistor and the broader corrosion resistor arrangement, part 215617 enhances the engine’s resistance to corrosion. This is particularly important in diesel engines, where the coolant is often exposed to more aggressive conditions. The head’s design allows for a more effective application of the coolant additive, ensuring that all surfaces are protected against the corrosive effects of diesel exhaust gases and other contaminants.

Role in the Corrosion Resistor Bracket and Mounting System

The corrosion resistor head is also a pivotal element in the corrosion resistor bracket and mounting system. It provides a secure and stable connection point for the corrosion resistor, ensuring that it remains firmly in place under the dynamic conditions of engine operation. This stability is essential for the consistent performance of the corrosion resistor, which relies on precise positioning to effectively shield critical engine components.

Contribution to Auxiliary Cooling and Radiator Systems

In auxiliary cooling systems, the corrosion resistor head plays a role in regulating the flow of coolant to and from the radiator. This regulation is key to maintaining the radiator’s efficiency, as it ensures that the coolant is not only cooled effectively but also distributed in a manner that maximizes heat exchange. The head’s design also contributes to the overall durability of the radiator, protecting it from the corrosive effects of the coolant.

Integration with Water Filter and Mounting

Lastly, the corrosion resistor head interfaces with the water filter and its mounting system. This integration is important for maintaining the purity of the coolant, as the water filter removes contaminants that could otherwise accelerate corrosion within the engine. The head’s role in this system is to ensure that the filtered coolant is delivered to all parts of the engine, enhancing the effectiveness of the water filter and prolonging the engine’s lifespan.

Conclusion

In summary, the Corrosion Resistor Head 215617 is a versatile component that enhances the functionality and durability of various engine systems. Its integration with base parts, manifold wet, auxiliary cooling, radiator, water filter, and corrosion protection components underscores its importance in maintaining engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.