This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4020105 O-Ring Seal is a critical component designed to maintain the integrity of fluid systems within commercial trucks. It ensures reliable sealing in various applications, contributing to the efficient operation of the vehicle. Understanding the function and significance of this part is essential for maintaining the performance and longevity of truck systems.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket that forms a seal by being compressed within a groove. It creates a barrier that prevents the leakage of fluids and gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility. They are commonly found in applications where dynamic sealing is required, such as in rotating or reciprocating machinery 1.

Purpose of the 4020105 O-Ring Seal

This Cummins part is specifically designed to operate within the fluid systems of commercial trucks. It is typically located in areas where fluid transfer occurs, such as in the fuel system or hydraulic components. The seal plays a role in maintaining the pressure and purity of the fluids by preventing leaks, which can lead to system inefficiencies or failures 2.

Key Features

The Cummins 4020105 O-Ring Seal is constructed from materials that offer high durability and resistance to various environmental factors. Its design characteristics include a precise fit within the designated groove, ensuring a tight seal. The material composition is chosen to withstand the operational stresses and temperatures encountered in truck systems, enhancing the seal’s performance and longevity.

Benefits

Utilizing the Cummins 4020105 O-Ring Seal provides several advantages. It offers improved sealing efficiency, which contributes to the overall performance of the truck’s systems. The seal’s durability ensures a longer service life, reducing the frequency of replacements. Additionally, its resistance to environmental factors such as temperature fluctuations and chemical exposure helps maintain its integrity over time.

Installation Process

Proper installation of the Cummins 4020105 O-Ring Seal is crucial for its effectiveness. The installation process involves cleaning the groove to ensure there is no debris that could compromise the seal. The O-Ring should be lubricated before insertion to facilitate placement and reduce the risk of damage. Careful handling is necessary to avoid distorting the O-Ring, which could lead to improper sealing.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks, which can be caused by improper installation, wear, or damage. Troubleshooting steps involve inspecting the seal for signs of wear or deformation, checking the groove for cleanliness and proper sizing, and ensuring that the seal is correctly installed. Addressing these issues promptly can prevent more significant problems within the truck’s systems.

Maintenance Tips

Regular maintenance of the Cummins 4020105 O-Ring Seal involves periodic inspection for signs of wear or damage. It is important to follow recommended replacement intervals to prevent leaks and maintain system efficiency. Keeping the seal and its surrounding components clean and free from contaminants also contributes to its longevity and performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company is committed to advancing technology and sustainability in the automotive industry, providing reliable and efficient solutions for its customers.

Cummins O-Ring Seal 4020105 Compatibility

The Cummins O-Ring Seal part number 4020105 is designed to fit seamlessly within various engine models, ensuring optimal sealing performance. This O-Ring Seal is engineered to meet the stringent requirements of high-performance engines, providing a reliable barrier against leaks and maintaining system integrity.

QSM11 Engines

The O-Ring Seal 4020105 is compatible with the QSM11 engine series. This seal is crucial in maintaining the efficiency and longevity of the QSM11 engines by preventing fluid and gas leaks in critical areas. Its precise fit ensures that the engine operates smoothly without any performance degradation.

CM570 Engines

Similarly, the O-Ring Seal 4020105 is also suitable for the CM570 engine series. In these engines, the seal plays a vital role in maintaining the pressure and integrity of the system. Its robust design ensures that it can withstand the operational stresses of the CM570 engines, providing a dependable seal that enhances overall engine performance.

Grouping of Engines

The O-Ring Seal 4020105 is engineered to fit both the QSM11 and CM570 engines, highlighting its versatility and broad compatibility. This compatibility is essential for technicians and engineers who need to ensure that their engines are equipped with the right parts to maintain peak performance and reliability.

Role of Part 4020105 O-Ring Seal in Engine Systems

The part 4020105 O-Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a significant role in the overall functionality of the engine.

Integration with Control Systems

In control systems, the O-Ring Seal is employed to maintain a secure and leak-proof connection between different modules. This ensures that fluids and gases are contained within their designated pathways, preventing any unwanted mixing or leakage that could compromise system performance. The seal’s elasticity and material properties are tailored to withstand the pressures and temperatures typical in control systems, thereby enhancing reliability and durability.

Application in Station Components

Station components, which often involve the handling of various media such as fuels, lubricants, and coolants, benefit significantly from the presence of the O-Ring Seal. By providing a robust barrier against leaks, the seal helps in maintaining the purity and pressure of these media. This is particularly important in stations where precise control over media properties is essential for optimal engine operation.

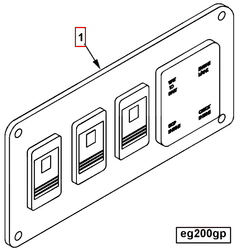

Function within Panel Assemblies

Panel assemblies in engine systems are designed to house and protect sensitive electronic and mechanical components. The O-Ring Seal is used in these assemblies to create a hermetic seal, safeguarding internal components from environmental factors such as moisture, dust, and corrosive agents. This protection is vital for the longevity and performance of the panel’s components, ensuring they operate within specified parameters.

Role in Switch Mechanisms

Switch mechanisms within engine systems often require precise and reliable operation. The O-Ring Seal is utilized in these mechanisms to ensure that moving parts remain lubricated and free from contaminants. This not only enhances the operational smoothness of the switch but also extends its service life by reducing wear and tear. The seal’s ability to adapt to dynamic conditions within the switch mechanism makes it an invaluable component in maintaining consistent performance.

Conclusion

The Cummins 4020105 O-Ring Seal plays a vital role in the efficient operation of commercial truck systems by ensuring reliable sealing in various applications. Its durability, resistance to environmental factors, and precise fit within designated grooves contribute to the overall performance and longevity of truck systems. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.