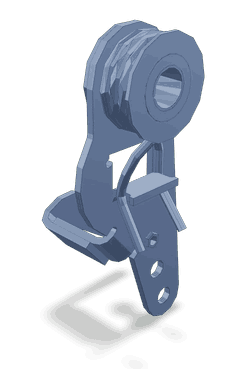

The Cummins 3930509 Control Linkage Lever is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and performance of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing the functionality of commercial trucks.

Basic Concepts of Control Linkage Levers

A Control Linkage Lever is a mechanical component that facilitates the transmission of motion or force within a truck’s system. It acts as a connector between different parts, allowing for the efficient transfer of mechanical action. This lever plays a role in ensuring that various components within the truck’s system operate in unison, contributing to the smooth functioning of the vehicle 1.

Purpose of the Cummins 3930509 Control Linkage Lever

The Cummins 3930509 Control Linkage Lever is designed to interact with other components within a truck’s mechanical system. Its specific role involves the precise transmission of motion, which is important for the operation of certain truck functions. This lever works in conjunction with other parts to ensure that the truck’s systems respond accurately to driver inputs and operational demands 2.

Key Features

The Cummins 3930509 Control Linkage Lever is constructed with attention to detail, utilizing materials that offer durability and reliability. Its design incorporates features that enhance its performance, such as a robust build that can withstand the rigors of heavy-duty applications. The lever’s construction ensures it can operate effectively under various conditions, contributing to the truck’s overall performance.

Benefits

The Cummins 3930509 Control Linkage Lever offers several advantages. Its design contributes to improved operational efficiency, allowing for smoother and more responsive truck operations. The lever’s durability ensures it can withstand the demands of heavy-duty use, while its reliability makes it a valuable component for maintaining the truck’s performance over time.

Installation and Integration

Proper installation and integration of the Cummins 3930509 Control Linkage Lever within a truck’s mechanical system are important for ensuring its effective operation. This process may involve adjustments or calibrations to ensure the lever functions correctly within the system. Following manufacturer guidelines during installation helps maintain the lever’s performance and the truck’s overall efficiency.

Troubleshooting Common Issues

Common issues with the Cummins 3930509 Control Linkage Lever may include misalignment or wear, which can affect its operation. Troubleshooting these problems involves identifying the source of the issue and applying the appropriate solution, such as realigning the lever or replacing worn components. Addressing these issues promptly helps maintain the lever’s performance and the truck’s operational efficiency.

Maintenance Tips

Routine maintenance of the Cummins 3930509 Control Linkage Lever is important for ensuring its longevity and optimal performance. This includes regular inspections to check for wear or damage and applying lubrication as needed to reduce friction and wear. Adhering to recommended maintenance practices helps preserve the lever’s condition and contributes to the truck’s reliable operation.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. The company has a history of innovation and quality, offering a variety of components and systems designed to enhance the performance and reliability of commercial vehicles. Cummins’ commitment to excellence is reflected in its product offerings, including the Cummins 3930509 Control Linkage Lever.

Cummins Control Linkage Lever 3930509 Compatibility

The Cummins Control Linkage Lever part number 3930509 is designed to fit seamlessly with a range of Cummins engines, ensuring precise control and operation. This part is integral to the engine’s functionality, providing the necessary linkage between the control system and the engine’s mechanical components.

B5.9 G and B5.9 GAS PLUS CM556 Engines

The Control Linkage Lever 3930509 is compatible with the B5.9 G and B5.9 GAS PLUS CM556 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The lever ensures that the control mechanisms are effectively translated into mechanical actions, maintaining the engine’s operational integrity.

G5.9 Engine

Similarly, the G5.9 engine also utilizes the Control Linkage Lever 3930509. This engine is designed for high-performance applications, and the precise operation of the control linkage is crucial for its efficient functioning. The lever’s design ensures that the control signals are accurately transmitted, contributing to the engine’s overall performance and longevity.

By ensuring compatibility with these engines, the Control Linkage Lever 3930509 plays a vital role in maintaining the operational efficiency and reliability of Cummins engines across various applications.

Role of Part 3930509 Control Linkage Lever in Engine Systems

The 3930509 Control Linkage Lever is an integral component in the orchestration of various engine systems, ensuring precise and responsive control over engine operations. This lever interfaces directly with the Air Fuel Throttle Valve (AFTV), a component responsible for regulating the air-fuel mixture entering the engine. The Control Linkage Lever translates mechanical motion into precise adjustments of the AFTV, optimizing the air-fuel ratio for efficient combustion.

In conjunction with the Assembly Kit, the 3930509 lever facilitates the secure and accurate mounting of the AFTV within the engine bay. The Assembly Kit typically includes brackets, mounts, and fasteners that ensure the AFTV is correctly positioned and aligned with other engine components. The Control Linkage Lever’s integration with this kit ensures that the mechanical linkage remains intact and functions smoothly under varying engine loads and conditions.

The Module, often an electronic control unit (ECU) or engine control module (ECM), relies on feedback from the Control Linkage Lever to make real-time adjustments to the engine’s performance. The lever’s position sensor sends signals to the Module, allowing it to fine-tune the fuel injection timing and air intake based on driving conditions, load, and throttle position. This dynamic interaction between the lever and the Module enhances overall engine efficiency and responsiveness.

Lastly, the Fuel Control system benefits significantly from the precise operation of the 3930509 lever. By ensuring that the AFTV opens and closes in sync with the engine’s requirements, the lever helps maintain a consistent fuel delivery rate. This consistency is vital for smooth engine operation, reduced emissions, and improved fuel economy. The lever’s role in this system underscores its importance in the broader context of engine management and performance optimization 3.

Conclusion

The Cummins 3930509 Control Linkage Lever is a critical component in the operation of commercial trucks, particularly those equipped with Cummins engines. Its role in ensuring precise control over engine operations, compatibility with various Cummins engines, and contribution to overall engine efficiency and performance make it an indispensable part of the truck’s mechanical system. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part and ensure the reliable operation of the vehicle.

-

Mohamed ElSayed PE, “Fundamentals of Integrated Vehicle Realization,” SAE International, 2017.

↩ -

Steve Rendle, Martynn Randall, “Haynes Diesel Engine Systems and Data Book,” Haynes Publishing, 2000.

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng, “Automotive Heating Ventilation and Air Conditioning,” Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.