This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

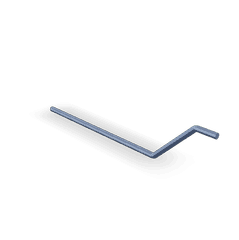

The Cummins 4099517 Control Rod is a component designed for use in commercial truck engines. It serves a specific function within the engine’s fuel injection system, contributing to the overall performance and efficiency of the vehicle. Understanding its role and significance can provide valuable insights into the operation of diesel engines in heavy-duty applications.

Basic Concepts of Control Rods

A control rod in a diesel engine is a mechanical component that regulates the operation of the fuel injection system. It interacts with various engine components to ensure precise fuel delivery, which is crucial for engine performance. The control rod’s function is to modulate the timing and quantity of fuel injected into the combustion chamber, thereby influencing engine power output and efficiency 2.

Purpose of the Cummins 4099517 Control Rod

The Cummins 4099517 Control Rod plays a role in the operation of a truck engine by facilitating the accurate and timely delivery of fuel. It is integral to the fuel injection system, where it helps maintain the correct fuel-air mixture for combustion. This ensures that the engine operates efficiently and produces the desired power output. The control rod’s precise function contributes to the engine’s overall performance and reliability 3.

Key Features

The Cummins 4099517 Control Rod is characterized by several key features that enhance its performance. It is constructed from durable materials to withstand the high stresses and temperatures within the engine environment. The design includes specific elements that allow for smooth operation and accurate fuel delivery. Additionally, the control rod may have unique characteristics that improve its durability and efficiency in demanding conditions 4.

Benefits

The Cummins 4099517 Control Rod offers several benefits that contribute to engine performance, reliability, and efficiency. By ensuring precise fuel delivery, it helps maintain optimal engine operation. This can lead to improved fuel economy, reduced emissions, and enhanced engine longevity. The control rod’s robust design also contributes to the overall reliability of the fuel injection system 2.

Installation Process

Proper installation of the Cummins 4099517 Control Rod is important for ensuring its effective operation. The process involves several steps, including the use of specific tools and equipment. It is important to follow manufacturer guidelines to ensure that the control rod is installed correctly and securely. This includes checking for proper alignment and ensuring that all connections are tight and secure 1.

Troubleshooting Common Issues

Common problems associated with the Cummins 4099517 Control Rod may include wear and tear, which can affect its performance. Regular inspection and maintenance can help identify issues early. Troubleshooting steps may involve checking for signs of damage, ensuring proper lubrication, and verifying that the control rod is functioning within specified parameters 3.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 4099517 Control Rod. This includes periodic inspection for wear and damage, ensuring that all connections are secure, and following manufacturer guidelines for maintenance intervals. Proper care and maintenance can help prevent issues and ensure that the control rod continues to operate effectively 4.

Compatibility and Applications

The Cummins 4099517 Control Rod is designed for use in specific types of engines and truck models. It is important to verify compatibility to ensure that the control rod is suitable for the intended application. This information can typically be found in the product documentation or by consulting with a knowledgeable professional 1.

Cummins Overview

Cummins Inc. is a well-established company with a significant presence in the commercial truck industry. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance engine components. The company’s commitment to excellence is reflected in its products, including the Cummins 4099517 Control Rod 2.

Cummins Control Rod 4099517 in KTA19GC Engines

The Cummins Control Rod 4099517 is a critical component in the KTA19GC engine series. This part is integral to the engine’s operation, ensuring the smooth and efficient functioning of the engine’s internal mechanisms. The KTA19GC engines, known for their robust performance and reliability, utilize the Control Rod 4099517 to maintain the precise movement of the engine’s pistons 3.

In the KTA19GC engines, the Control Rod 4099517 connects the piston to the crankshaft, allowing for the transfer of power generated by the combustion process. This connection is vital for the engine’s ability to convert fuel into mechanical energy, which is then used to power various applications. The design and material of the Control Rod 4099517 are optimized to withstand the high stresses and temperatures encountered during engine operation, ensuring durability and longevity 4.

The Control Rod 4099517 is engineered to fit seamlessly within the KTA19GC engine architecture, providing a reliable and consistent performance. Its precise dimensions and tolerances ensure a perfect fit, allowing for efficient operation and minimal wear over time. This part is a testament to Cummins’ commitment to quality and precision, which is evident in the performance and reliability of the KTA19GC engines 1.

Integration of Part 4099517 Control Rod in Engine Systems

The part 4099517 Control Rod is an integral component in the orchestration of engine operations, specifically within the governor system. Its role is to facilitate precise control and regulation of engine speed, ensuring optimal performance and efficiency.

Governor Mounting

The control rod interfaces directly with the governor mounting, which is the foundational structure that supports the governor mechanism. This connection is essential for maintaining the stability and alignment of the governor as it modulates engine speed. The control rod’s attachment to the governor mounting allows for the transmission of mechanical force, enabling the governor to respond to changes in engine load and adjust the throttle accordingly 2.

Linkage

Within the engine’s control system, the linkage serves as the intermediary between the control rod and other components. The control rod is connected to the linkage, which in turn is linked to the throttle mechanism. This arrangement allows for the smooth and accurate transfer of motion from the governor to the throttle, ensuring that the engine speed is adjusted in a controlled and responsive manner. The precision of this linkage is vital for the engine’s ability to maintain consistent performance under varying conditions 3.

Governor Control

The governor control is the brain of the engine’s speed regulation system. The control rod plays a significant role in this subsystem by conveying the necessary mechanical signals from the governor to the throttle. As the engine’s load changes, the governor control sends signals through the control rod to adjust the throttle position, thereby modulating the engine’s speed. This dynamic interaction is key to the engine’s ability to operate efficiently across a range of operational demands 4.

Conclusion

In summary, the part 4099517 Control Rod is a pivotal element in the engine’s governor system, ensuring that the engine operates within the desired speed parameters by facilitating the communication between the governor, linkage, and throttle mechanism. Its integration into the engine system underscores the importance of precise control and regulation in achieving optimal engine performance and efficiency.

-

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5411385.

↩ ↩ ↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ ↩ ↩ ↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ ↩ ↩ ↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.