The S10081 Female Connector, manufactured by Cummins, is a specialized component designed for use in commercial truck systems. This connector serves as an interface point within various electrical and fluid systems, facilitating the transfer of power or fluids between components. A female connector, in general, is characterized by its receptacle design, which allows it to receive a corresponding male connector. This design is prevalent in automotive applications for its secure and reliable connection capabilities 1.

Basic Concepts of Female Connectors

Female connectors are integral to both electrical and fluid systems in vehicles. They function by providing a secure and stable connection point for male connectors, ensuring efficient transfer of power or fluids. The primary distinction between male and female connectors lies in their design: male connectors feature protruding pins or tubes, while female connectors have corresponding sockets or receptacles. This complementary design ensures a snug fit, reducing the risk of disconnection and enhancing system reliability 2.

Purpose of the S10081 Female Connector

The S10081 Female Connector plays a specific role in the operation of commercial trucks by interfacing with various system components. It is designed to connect with corresponding male connectors, facilitating the transfer of electrical signals or fluids. This connector contributes to the overall system functionality by ensuring a reliable and consistent connection, which is vital for the proper operation of the truck’s systems 3.

Key Features

The S10081 Female Connector is constructed from high-quality materials, ensuring durability and resistance to wear and corrosion. Its design includes features such as a robust housing, secure locking mechanisms, and precise alignment guides to ensure a perfect fit with male connectors. These attributes enhance the connector’s performance and longevity, making it suitable for the demanding conditions of commercial truck applications.

Benefits

Using the S10081 Female Connector offers several advantages. Its design ensures improved reliability in connections, reducing the likelihood of system failures due to disconnections. The connector is also designed for ease of installation, with features that simplify the connection process. Additionally, it is compatible with specific truck models and systems, ensuring seamless integration into existing setups.

Installation Process

Installing the S10081 Female Connector involves several steps to ensure a secure and proper connection. Begin by identifying the correct location for the connector within the system. Use the appropriate tools to prepare the connection point, ensuring it is clean and free from debris. Align the connector with the male counterpart and engage the locking mechanism to secure the connection. Verify the connection by checking for proper alignment and a snug fit.

Common Issues and Troubleshooting

Common issues with female connectors, including the S10081, may include poor connections, corrosion, and wear. To address these problems, regularly inspect the connectors for signs of damage or corrosion. Clean the connectors using appropriate cleaning solutions to remove any buildup. If wear is detected, consider replacing the connector to maintain system integrity. Ensuring proper installation and regular maintenance can prevent many common issues.

Maintenance Tips

To ensure the longevity and optimal performance of the S10081 Female Connector, regular maintenance is recommended. Inspect the connector periodically for signs of wear, corrosion, or damage. Clean the connector and its mating surfaces to remove any contaminants that could affect the connection. Follow the manufacturer’s guidelines for maintenance procedures to keep the connector in top condition.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components for commercial vehicles. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance parts. Their expertise in engine technology and component design ensures that products like the S10081 Female Connector meet the rigorous demands of commercial truck applications.

Cummins Engine Compatibility with S10081 Female Connector

The S10081 Female Connector, manufactured by Cummins, is designed to ensure seamless integration and functionality within various engine models. This part is engineered to fit precisely with several Cummins engine series, enhancing the overall performance and reliability of the engines.

Cummins 4B3.9 and 6B5.9 Engines

The S10081 Female Connector is compatible with the Cummins 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and are widely used in various applications. The connector ensures that the fuel and fluid lines are securely attached, preventing leaks and maintaining optimal engine efficiency.

Cummins 6C8.3 and QSC8.3 Engines

The S10081 Female Connector also fits the Cummins 6C8.3 and QSC8.3 engines. These engines are part of Cummins’ lineup of high-performance diesel engines, often utilized in heavy-duty applications. The connector’s precise fit ensures that the engines operate smoothly, with no interruptions in fluid flow.

Cummins CM850 (CM2850) and V28 Engines

For the Cummins CM850 (CM2850) and V28 engines, the S10081 Female Connector is an essential component. These engines are known for their durability and are commonly used in industrial and marine applications. The connector’s design ensures that the engines can withstand the rigors of continuous operation while maintaining a secure connection.

Cummins V903 Engine

The Cummins V903 engine is another model that benefits from the S10081 Female Connector. This engine is part of Cummins’ range of high-output diesel engines, often used in demanding environments. The connector’s compatibility with the V903 engine ensures that the engine’s performance is not compromised, even under heavy loads.

By integrating the S10081 Female Connector into these Cummins engines, users can expect enhanced reliability, improved performance, and a reduction in maintenance issues related to fluid connections.

Role of S10081 Female Connector in Engine Systems

The S10081 Female Connector is an integral component in various engine systems, facilitating the secure and efficient connection of multiple parts. Its application spans across several critical areas within the engine arrangement, ensuring optimal performance and reliability.

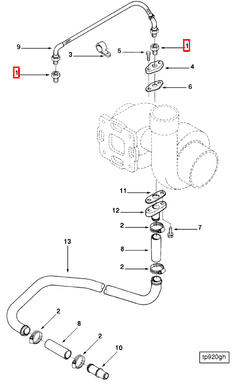

Turbocharger Systems

In turbocharger applications, the S10081 Female Connector is often used in the turbocharger hose and turbocharger oil supply hose connections. It ensures a leak-free seal, which is essential for maintaining the turbocharger’s efficiency and durability. Additionally, it plays a role in the turbocharger mounting and turbocharger mounting kit by providing stable and secure connections between the turbocharger and other engine components.

Fuel System Integration

Within the fuel system, the S10081 Female Connector is employed in several key areas. It is used in the fuel pump inlet fitting to ensure a secure connection between the fuel pump and the fuel supply tube. This connector is also vital in the fuel supply tubing and fuel tube connections, guaranteeing consistent fuel flow to the engine. Furthermore, it is utilized in the fuel drain tube to facilitate efficient drainage of excess fuel, preventing potential contamination and system malfunctions.

Actuator and Solenoid Valve Connections

The S10081 Female Connector is instrumental in Bosch actuator plumbing, where it ensures precise and reliable connections between the actuator and other components. In solenoid valve applications, it provides a secure fitting, enabling accurate control of fluid flow within the engine system.

Safety and Control Systems

In the Amot safety control and Amot system mounting, the S10081 Female Connector ensures that all connections are robust and dependable. This is particularly important in high-stress environments where safety and precise control are paramount.

Exhaust and Emission Control

The connector is also used in the muffler and turbocharger mounting, contributing to the efficient management of exhaust gases. Additionally, in the water drain tube and mounting, it ensures that condensation and water are effectively drained from the system, preventing corrosion and maintaining engine health.

General Plumbing and Fittings

Across various lines and fittings, such as those from the fuel pump to the block (FP to BL) and general tubing and fitting applications, the S10081 Female Connector provides reliable and durable connections. This is essential for the integrity of the engine’s fluid dynamics and overall performance.

Conclusion

In summary, the S10081 Female Connector plays a significant role in ensuring the secure and efficient operation of various engine components, contributing to the overall reliability and performance of the engine system. Regular maintenance and proper installation are crucial to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.