This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

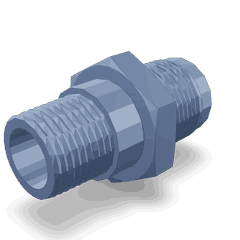

The Cummins Male Connector 69461 is a specialized component designed for use in commercial trucks. It plays a role in ensuring the efficient operation of various truck systems by facilitating secure and reliable connections. This connector is integral to maintaining the functionality and performance of the truck’s systems, contributing to overall operational efficiency.

Basic Concepts of Male Connectors

Male connectors are components used in systems to establish connections between different parts. They typically feature a protruding pin or plug that fits into a corresponding female connector. In automotive and industrial applications, male connectors are utilized for electrical, hydraulic, and pneumatic systems, ensuring seamless data, power, or fluid transfer. Their design allows for easy assembly and disassembly, which is important for maintenance and system upgrades 1.

Purpose of the 69461 Male Connector

The 69461 Male Connector is specifically designed to play a role in the truck’s systems by providing a secure connection point. It ensures that electrical signals, fluids, or gases are transmitted efficiently between components. This connector is part of the truck’s infrastructure, supporting various functions such as engine management, transmission control, and auxiliary systems. Its reliable connection capability is vital for the consistent performance of these systems 2.

Key Features

The 69461 Male Connector is constructed from high-quality materials, ensuring durability and resistance to wear and environmental factors. Its design includes features such as corrosion-resistant coatings and robust locking mechanisms to maintain a secure connection. These elements contribute to the connector’s longevity and reliability, making it suitable for the demanding conditions encountered in commercial trucking 3.

Benefits

Utilizing the 69461 Male Connector offers several advantages. It enhances system efficiency by ensuring stable and reliable connections, which is important for the optimal operation of truck systems. The connector’s design also contributes to the overall reliability of the truck, reducing the likelihood of connection-related failures. Additionally, its durability can lead to cost savings for fleet operators by minimizing the need for frequent replacements.

Installation and Compatibility

Proper installation of the 69461 Male Connector is important for its effective operation. It requires precise alignment and secure fastening to ensure a stable connection. Compatibility with various truck models and systems is a key consideration, as it ensures that the connector can be used across different applications without requiring modifications. Following manufacturer guidelines for installation and compatibility is recommended to achieve the best performance.

Maintenance and Troubleshooting

Regular maintenance of the 69461 Male Connector is important for ensuring its longevity and optimal performance. This includes checking for signs of wear, corrosion, or damage and cleaning the connector as necessary. Common issues that may arise include loose connections or corrosion, which can be addressed by tightening the connector or applying a corrosion-resistant treatment. Adhering to maintenance schedules and performing routine inspections can help prevent issues and ensure reliable operation.

Safety Considerations

When working with the 69461 Male Connector, observing safety guidelines is important. This includes ensuring that the truck is powered down before attempting any installation or maintenance to prevent electrical shocks. Using the appropriate tools and following manufacturer instructions can help avoid damage to the connector or surrounding components. Additionally, wearing protective gear, such as gloves and safety glasses, is recommended when handling the connector to protect against injuries.

Environmental Impact

The manufacturing, use, and disposal of the 69461 Male Connector have environmental considerations. Efforts are made to minimize the environmental impact through the use of recyclable materials and efficient manufacturing processes. Proper disposal or recycling of the connector at the end of its life cycle is encouraged to reduce waste and environmental harm. Following local regulations and guidelines for disposal ensures responsible management of the component.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and transportation markets. The company is committed to advancing technology and sustainability in the automotive and industrial sectors, providing reliable and efficient solutions to meet the needs of its customers.

Cummins Male Connector 69461 Compatibility

The Cummins Male Connector part number 69461 is designed to fit a variety of Cummins engines, ensuring seamless integration and compatibility across different models. This connector is integral for maintaining fluid flow and pressure within the engine’s systems. Below is a detailed overview of the engines with which this part is compatible:

- Cummins 6B5.9 Engines: The 6B5.9 engine series benefits from the 69461 connector, ensuring reliable connections for fuel, oil, and other critical fluids.

- Cummins 6C8.3 Engines: Similarly, the 6C8.3 engine series utilizes the 69461 connector, providing a robust solution for maintaining fluid integrity and performance.

- Cummins QSB5.9 CM850 Engines: The QSB5.9 CM850 engines are equipped with the 69461 connector, ensuring that the engine’s fluid systems operate efficiently and without leaks.

- Cummins QSC8.3 CM850 (CM2850) Engines: The QSC8.3 CM850 (CM2850) engines also incorporate the 69461 connector, facilitating the smooth transfer of fluids necessary for engine operation.

- Cummins K19 Engines: The K19 engine series is another beneficiary of the 69461 connector, ensuring that all fluid connections are secure and reliable.

- Cummins QSK19 CM500 Engines: The QSK19 CM500 engines use the 69461 connector, providing a critical component for maintaining the engine’s fluid systems.

- Cummins K38 Engines: The K38 engine series is compatible with the 69461 connector, ensuring that fluid connections are both secure and efficient.

- Cummins K50 Engines: The K50 engine series also uses the 69461 connector, ensuring that the engine’s fluid systems are maintained with high reliability.

- Cummins QSK50 CM2150 MCRS Engines: The QSK50 CM2150 MCRS engines incorporate the 69461 connector, providing a dependable solution for fluid connections.

- Cummins L10 MECHANICAL Engines: The L10 MECHANICAL engines are designed to work with the 69461 connector, ensuring that all fluid systems are properly connected and maintained.

- Cummins N14 CELECT PLUS Engines: The N14 CELECT PLUS engines use the 69461 connector, ensuring that the engine’s fluid systems are reliable and efficient.

- Cummins N14 MECHANICAL Engines: The N14 MECHANICAL engines are compatible with the 69461 connector, providing a robust solution for fluid connections.

- Cummins NH/NT 855 Engines: The NH/NT 855 engines incorporate the 69461 connector, ensuring that all fluid systems are properly connected and maintained.

- Cummins ISB CM550 Engines: The ISB CM550 engines use the 69461 connector, ensuring that the engine’s fluid systems are reliable and efficient.

By ensuring compatibility with these various engine models, the Cummins Male Connector part number 69461 provides a versatile and reliable solution for maintaining fluid integrity and performance across a wide range of Cummins engines.

Role of Part 69461 Male Connector in Engine Systems

The Part 69461 Male Connector is integral to the seamless operation of various engine systems by ensuring secure and efficient fluid transfer between components. Here’s how it interfaces with the provided components:

Fuel System Integration

- Fuel Supply Plumbing: The Male Connector is often used to join sections of fuel supply lines, ensuring a leak-free connection that maintains consistent fuel pressure and flow to the engine.

- Fuel Tank and Fuel Transfer Tank: It facilitates the connection between the fuel tank and the transfer tank, allowing for efficient fuel distribution and management.

- Fuel Pump Inlet Fitting: This connector is vital for linking the fuel pump inlet to the fuel supply line, ensuring the pump receives an uninterrupted fuel supply.

- Fuel Shutoff Valve: It plays a role in connecting the shutoff valve to the fuel lines, enabling controlled fuel flow to the engine.

- Fuel Tube and Fuel Cooler: The Male Connector is used to join fuel tubes and coolers, maintaining the integrity of the fuel as it is circulated through the system.

- Fuel By-Pass Assembly: It ensures a secure connection in by-pass systems, allowing fuel to circumvent certain components when necessary.

Cooling and Ventilation Systems

- Engine Coolant Vent: The connector is employed to link the coolant vent to the rest of the cooling system, aiding in pressure regulation and coolant flow.

- Float Tank: It connects the float tank to the fuel system, ensuring accurate fuel level measurement and delivery.

Lubrication and Oil Systems

- Oil Bypass Filter: The Male Connector is used to join the oil bypass filter to the lubrication system, allowing oil to flow through or around the filter as needed.

- Remote Oil Drain: It facilitates the connection for remote oil drain systems, simplifying the oil change process.

Specialized Plumbing and Hoses

- Aeroquip Gear Hose and Reverse Gear Hose: The connector is utilized to join these hoses to their respective systems, ensuring reliable fluid transfer in transmission applications.

- Campaign Kit and Kit Conversion: It is integral in assembling these kits, providing secure connections for various fluid lines.

- Check Valve: The Male Connector is used to integrate check valves into fluid systems, preventing backflow and ensuring unidirectional fluid movement.

- S.T.C. Plumbing and Step Mounting Plumbing: It connects these specialized plumbing components, enhancing the overall fluid management within the engine system.

- Transfer Pump Plumbing: The connector is essential for linking transfer pump plumbing, ensuring efficient fluid transfer between reservoirs.

Turbocharger and Air Systems

- Turbocharger Plumbing: It is used to connect various sections of turbocharger plumbing, ensuring optimal airflow and performance.

- Air Compressor Plumbing: The Male Connector joins air compressor lines, maintaining pressure and flow integrity within the system.

Miscellaneous Applications

- EBM: Plumbing and EBM: Tubing: The connector is employed in these systems to ensure secure and reliable fluid connections.

- Plumbing Step: It is used in multi-step plumbing configurations to maintain fluid continuity and pressure.

The Part 69461 Male Connector thus serves as a fundamental component in various engine systems, ensuring secure, efficient, and leak-free fluid connections across a wide range of applications.

Conclusion

The Cummins Male Connector 69461 is a critical component in the operation of commercial trucks, ensuring secure and efficient connections across various systems. Its high-quality construction, compatibility with multiple Cummins engines, and role in maintaining fluid integrity make it an essential part of truck maintenance and performance. Regular maintenance, proper installation, and adherence to safety guidelines are important for maximizing the benefits of this connector.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.