This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

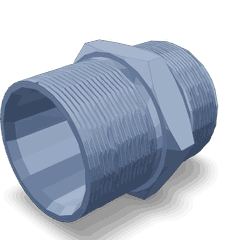

The Cummins 3060051 Male Connector is a specialized component designed for use in commercial truck operations. It serves as a link in various systems within the truck, ensuring the efficient transfer of fluids or gases. Its role is significant in maintaining the overall functionality and performance of the vehicle.

Basic Concepts of Male Connectors

Male connectors are components used to join two parts of a system together, typically by fitting into a corresponding female connector. They are integral in systems requiring the transfer of fluids, gases, or electrical signals. In automotive and industrial settings, male connectors ensure secure and leak-proof connections, which are vital for the operation and safety of the equipment 1.

Purpose of the Cummins 3060051 Male Connector

The Cummins 3060051 Male Connector is specifically designed to facilitate the connection between different parts of a truck’s system. It plays a role in ensuring the smooth operation of the truck by providing a reliable connection point for fluid or gas transfer. This connector is part of the truck’s broader system, contributing to its overall efficiency and reliability.

Key Features

The Cummins 3060051 Male Connector is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operations. Its design includes features that enhance its performance, such as a precise fit that ensures a secure connection and resistance to wear and corrosion. These characteristics contribute to the connector’s longevity and reliability in demanding environments.

Benefits

The use of the Cummins 3060051 Male Connector offers several advantages. It contributes to improved system efficiency by ensuring a secure and leak-proof connection. Its reliable performance reduces the likelihood of system failures, enhancing the truck’s overall reliability. Additionally, the connector’s durability minimizes the need for frequent replacements, contributing to lower maintenance costs.

Installation Considerations

Proper installation of the Cummins 3060051 Male Connector is crucial for its effective performance. It is recommended to follow manufacturer guidelines for installation, which may include preparatory steps such as cleaning the connection points and using the appropriate tools to ensure a secure fit. Attention to these details during installation can prevent common issues and ensure the connector functions as intended.

Troubleshooting Common Issues

Male connectors, including the Cummins 3060051, may encounter issues such as leaks or poor connections. These problems can often be traced back to improper installation or wear and tear. Diagnostic steps may involve inspecting the connection points for signs of damage or corrosion and ensuring that the connector is properly seated. Solutions may range from cleaning and re-securing the connection to replacing the connector if it is damaged.

Maintenance Tips

Regular maintenance of the Cummins 3060051 Male Connector is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning the connection points to remove any debris or corrosion, and replacing the connector if it shows signs of significant wear. Adhering to these maintenance practices can help prevent issues and ensure the connector continues to perform reliably.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, offering a wide range of products designed to enhance the performance, efficiency, and reliability of commercial vehicles 2.

Compatibility with Various Engine Models

The Cummins Male Connector 3060051 is a versatile component designed to fit seamlessly with a range of Cummins engine models. This part is integral to the proper functioning of the engine’s fuel and fluid systems, ensuring efficient operation and reliability.

K38 and K50 Engines

The K38 and K50 engines, known for their robust performance and durability, are compatible with the Cummins Male Connector 3060051. This part is essential for maintaining the integrity of the fuel and fluid lines, preventing leaks and ensuring that the engine operates at peak efficiency. Its design allows for a secure connection, which is crucial for the high-pressure environments these engines operate in.

N14 MECHANICAL Engines

The N14 MECHANICAL engine series, a staple in heavy-duty applications, also benefits from the use of the Cummins Male Connector 3060051. This part is engineered to withstand the demanding conditions of these engines, providing a reliable connection point for various fluid lines. Its compatibility with the N14 MECHANICAL ensures that the engine’s fluid systems remain intact, contributing to the overall longevity and performance of the engine.

NH/NT 855 Engines

The NH/NT 855 engines, recognized for their versatility and power, are another series that can utilize the Cummins Male Connector 3060051. This part’s design is tailored to fit the specific needs of these engines, ensuring that the connections are both secure and durable. Its use in the NH/NT 855 engines helps maintain the efficiency of the engine’s fluid systems, which is critical for the engine’s optimal operation.

Role of Part 3060051 Male Connector in Engine Systems

The 3060051 Male Connector is integral to the efficient operation of various engine systems, facilitating secure and reliable connections between components.

- Air Pilot Relay Mounting: The Male Connector ensures a steadfast link between the relay and its mounting bracket, allowing for precise control of air flow and pressure. This connection is vital for the accurate modulation of engine functions.

- Air Pilot Relay V/V Mounting: The Male Connector provides a robust interface that supports the relay’s operation within the valve system, ensuring consistent performance and responsiveness in engine control.

- Air Pilot Relay Valve Mounting: The Male Connector is essential for maintaining the integrity of the valve’s connection to its mounting, necessary for the valve to function correctly, regulating air flow as required by the engine’s operational demands.

- Air Starter System: The Male Connector is used to establish a reliable connection between the starter and its associated plumbing, ensuring that the starter receives the necessary air supply to function effectively, contributing to the engine’s starting process.

- Air Starter Plumbing: The Male Connector is employed to join various sections of the plumbing, ensuring a leak-free and secure system. This is important for maintaining the pressure and flow of air required for the starter to operate.

- Dual Starter Systems: The Male Connector is utilized to connect the dual starters to their respective components, ensuring that both starters can operate in unison or independently, as required, providing redundancy and reliability in engine starting.

- Starting Motor System: The Male Connector is used to link the motor to its power source and control circuits, ensuring that the motor receives the necessary electrical and mechanical connections to function correctly, aiding in the engine’s starting process.

Conclusion

The Cummins 3060051 Male Connector plays a crucial role in the efficient operation of various engine systems by facilitating secure and reliable connections between components. Its compatibility with a range of Cummins engine models underscores its importance in maintaining the integrity and performance of the engine’s fluid systems. Proper installation, regular maintenance, and troubleshooting of common issues are essential to ensure the longevity and optimal performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.