This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

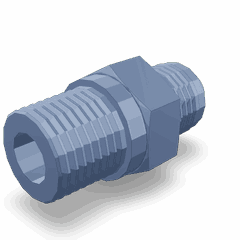

The Cummins 3049118 Male Connector is a specialized component designed for use in commercial truck operations. It plays a significant role in ensuring the efficient and reliable operation of various truck systems. Understanding its purpose and functionality is important for maintaining and optimizing truck performance.

Basic Concepts of Male Connectors

Male connectors are components used to join two parts of a system together, typically by fitting into a corresponding female connector. They are integral in automotive and industrial applications for establishing secure and reliable connections. These connectors facilitate the transfer of fluids, gases, or electrical signals between different parts of a system, ensuring seamless operation and communication 1.

Purpose of the 3049118 Male Connector

The Cummins 3049118 Male Connector is specifically designed to provide a secure connection point in the truck’s systems. It is used in various applications where a reliable and durable connection is required, such as in fuel systems, hydraulic systems, or pneumatic systems. Its function is to ensure that the connection remains intact under operational conditions, contributing to the overall efficiency and safety of the truck.

Key Features

The Cummins 3049118 Male Connector is characterized by several key features that enhance its performance. It is typically made from high-quality materials that offer durability and resistance to corrosion. The design includes precise threading and sealing mechanisms to ensure a tight and leak-proof connection. Additionally, it may feature unique characteristics such as anti-vibration properties to maintain stability during operation 2.

Benefits

The use of the Cummins 3049118 Male Connector offers several benefits. It provides improved connectivity, ensuring that systems operate without interruptions. Its durable construction contributes to longevity, reducing the need for frequent replacements. Furthermore, it enhances efficiency by maintaining secure connections, which is vital for the optimal performance of truck systems.

Installation Process

Installing the Cummins 3049118 Male Connector involves several steps to ensure a proper and secure fit. Begin by identifying the correct location for the connector within the system. Use the appropriate tools to clean the connection point, ensuring it is free from debris and contaminants. Carefully thread the male connector into the corresponding female connector, ensuring it is tightened to the manufacturer’s specifications. Verify the connection for leaks or loose fittings before finalizing the installation.

Troubleshooting Common Issues

Common problems with male connectors can include leaks, loose connections, or corrosion. To address these issues, first, inspect the connection for any visible signs of damage or wear. Tighten the connector if it appears loose, ensuring it is secure without over-tightening. If corrosion is present, clean the affected areas thoroughly before reassembling. In cases of persistent leaks, consider replacing the connector to ensure a reliable connection.

Maintenance Tips

Regular maintenance of the Cummins 3049118 Male Connector is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the connector and its surrounding areas can prevent the buildup of contaminants that may affect its function. Additionally, following the manufacturer’s guidelines for replacement can help maintain system integrity and efficiency.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted partner for commercial vehicle operators worldwide.

Cummins Male Connector 3049118 Compatibility

The Cummins Male Connector part number 3049118 is designed to fit seamlessly with a variety of Cummins engines, ensuring compatibility and reliable performance across different models. This part is engineered to meet the stringent quality and performance standards set by Cummins, providing a robust connection in various engine applications.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- L10 GAS

- M11 CELECT PLUS

- M11 MECHANICAL

- QSM11 CM570

These engines, known for their durability and efficiency, benefit from the precise fit and functionality of the 3049118 Male Connector. Whether used in industrial, agricultural, or transportation applications, this connector ensures a secure and leak-free connection, enhancing the overall performance of the engine.

Role of Part 3049118 Male Connector in Engine Systems

The part 3049118 Male Connector is an essential component that facilitates the connection and efficient operation of various engine systems. Its role is pivotal in ensuring seamless integration and functionality across different components.

Air Compressor

In the air compressor system, the Male Connector is utilized to link the compressor to the air intake and distribution lines. This ensures a secure and leak-free connection, which is vital for maintaining the desired air pressure and flow necessary for the compressor’s operation.

Coolant Heater Starting Aid

For the coolant heater starting aid, the Male Connector plays a significant role in connecting the heating element to the coolant lines. This ensures that the heated coolant is effectively circulated through the engine block, aiding in quicker starts in cold conditions and enhancing overall engine performance.

Coolant Heater Starting Aid Plumbing

In the context of coolant heater starting aid plumbing, the Male Connector is used to join various sections of the plumbing system. This ensures a consistent and reliable flow of heated coolant, which is essential for the efficient operation of the starting aid system.

Engine Oil Cooler

The Male Connector is integral to the engine oil cooler system, where it connects the cooler to the engine’s oil lines. This connection is crucial for maintaining optimal oil temperature, which in turn ensures the longevity and efficiency of the engine.

Fuel Transfer Pump

In fuel transfer pump applications, the Male Connector is used to link the pump to the fuel lines. This ensures a secure and efficient transfer of fuel, which is essential for the consistent operation of the engine.

Full Flow Oil Filter

For the full flow oil filter, the Male Connector is employed to connect the filter to the engine’s oil lines. This ensures that the oil flows smoothly through the filter, allowing for effective filtration and maintaining the cleanliness of the engine oil.

Turbocharger Mounting Kit

In the turbocharger mounting kit, the Male Connector is used to connect various components of the turbocharger system. This ensures a secure and efficient connection, which is vital for the turbocharger’s performance and the overall efficiency of the engine.

Turbocharger Plumbing

Finally, in turbocharger plumbing, the Male Connector is utilized to join the turbocharger to the intake and exhaust systems. This ensures a leak-free and efficient flow of air, which is essential for the turbocharger’s operation and the engine’s performance.

Conclusion

The Cummins 3049118 Male Connector is a critical component in ensuring the efficient and reliable operation of various truck systems. Its durable construction, precise design, and compatibility with a wide range of Cummins engines make it an essential part for maintaining optimal performance and longevity in commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.