This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

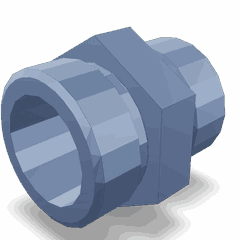

The Cummins 3040948 Male Connector is a specialized component designed for use in commercial trucks. It serves as a link in various systems within these vehicles, ensuring efficient and reliable operation. Understanding its purpose and functionality is key to maintaining the performance and longevity of commercial trucks.

Basic Concepts of Male Connectors

Male connectors are components used to join two parts of a system together. They typically feature a protruding pin or plug that fits into a corresponding female connector. In automotive and industrial applications, male connectors facilitate the transfer of fluids, gases, or electrical signals between components. Their design ensures a secure and leak-proof connection, which is vital for the safe and efficient operation of machinery 1.

Purpose of the Cummins 3040948 Male Connector

The Cummins 3040948 Male Connector provides a reliable connection point within the truck’s systems. It is designed to interface with various components, ensuring the smooth transfer of necessary fluids or signals. Its function is integral to maintaining the operational integrity of the truck’s systems, contributing to overall vehicle performance.

Key Features

The Cummins 3040948 Male Connector is characterized by several key features that enhance its performance and durability. These include a robust design that withstands the rigors of commercial truck operation, the use of high-quality materials resistant to wear and corrosion, and unique design elements that ensure a secure connection. These features contribute to the connector’s reliability and longevity in demanding applications.

Benefits

Utilizing the Cummins 3040948 Male Connector offers several advantages. It provides improved connectivity within the truck’s systems, enhancing operational efficiency. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, the secure connection it offers minimizes the risk of leaks or disconnections, contributing to safer and more efficient truck operations.

Installation Considerations

Proper installation of the Cummins 3040948 Male Connector is crucial for its effective operation. It requires careful alignment with the corresponding female connector and may necessitate specific tools to ensure a secure fit. Following manufacturer guidelines during installation helps prevent damage to the connector and ensures optimal performance within the truck’s systems.

Troubleshooting Common Issues

Common issues with male connectors can include poor connections, leaks, or damage from wear and tear. Troubleshooting the Cummins 3040948 Male Connector involves inspecting the connection for signs of wear, ensuring proper alignment, and checking for any obstructions that may prevent a secure fit. Addressing these issues promptly can help maintain the connector’s performance and the overall efficiency of the truck’s systems.

Maintenance Tips

Regular maintenance of the Cummins 3040948 Male Connector is important for ensuring its longevity and reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the connector to remove any debris that may affect its operation, and ensuring that all connections are secure. Adhering to these maintenance practices helps prevent issues and ensures the connector continues to function effectively.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for commercial truck operators worldwide.

Compatibility of Male Connector Part 3040948 with Cummins Engines

The Male Connector part 3040948, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring seamless integration and reliable performance. Below is a detailed overview of the engines with which this part is compatible:

6C Series Engines

- 6C8.3

- C8.3 G

ISM Series Engines

- ISM CM550

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

ISB Series Engines

- ISB CM550

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

N14 Series Engines

- N14 CELECT PLUS

- N14 MECHANICAL

QSB Series Engines

- QSB5.9 44 CM550

QSM Series Engines

- QSM11 CM570

Other Series Engines

- C GAS PLUS CM556

- K38

- K50

- NH/NT 855

This Cummins part is engineered to meet the specific requirements of these engines, providing a robust and durable connection that enhances the overall functionality and longevity of the engine systems.

Role of Part 3040948 Male Connector in Engine Systems

The Part 3040948 Male Connector is a component in various engine systems, facilitating the secure and efficient transfer of fluids and gases. Its application spans across multiple components, ensuring optimal performance and reliability.

Integration with Air Compressor Systems

In air compressor systems, the Male Connector is utilized to join different sections of the compressor, ensuring a leak-free connection. It plays a significant role in maintaining the integrity of the compressed air flow, which is vital for the compressor’s efficiency and durability.

Compressor Conversion Kit

When installing a compressor conversion kit, the Male Connector is often used to interface new components with the existing system. This ensures that the conversion process is seamless, allowing for upgraded performance without compromising the system’s reliability.

Compressor Coolant Arrangement

The compressor coolant arrangement relies on the Male Connector to link various coolant lines. This connection is imperative for maintaining consistent coolant flow, which is essential for regulating the compressor’s temperature and preventing overheating.

Compressor Coolant Plumbing

In the compressor coolant plumbing system, the Male Connector ensures that all coolant lines are securely attached. This is important for maintaining the coolant’s pressure and flow rate, which directly impacts the compressor’s cooling efficiency.

Compressor Water Drain Tube

The compressor water drain tube system uses the Male Connector to ensure that water is effectively drained from the compressor. This helps in preventing water accumulation, which could lead to corrosion and reduced compressor lifespan.

Mounting and Compressor Water Outlet Tube

For the mounting and compressor water outlet tube, the Male Connector provides a robust connection point. This ensures that the water outlet tube is firmly attached, allowing for efficient water drainage and maintaining the compressor’s operational integrity.

Mounting Compressor Air

In systems where mounting compressor air is required, the Male Connector plays a role in securing air lines. This is important for maintaining consistent air pressure and flow, which is crucial for the compressor’s performance.

Plumbing and Comp. Coolant

The plumbing and comp.coolant systems benefit from the Male Connector by ensuring that all coolant lines are properly connected. This maintains the coolant’s circulation, which is essential for temperature regulation within the compressor.

Compr Coolant and Water Drain Tube

Finally, in the compr coolant and water drain tube systems, the Male Connector ensures that both coolant and water lines are securely joined. This is vital for maintaining the overall efficiency and reliability of the compressor system.

Conclusion

The Cummins 3040948 Male Connector is a vital component in the operation of commercial trucks and various engine systems. Its robust design, compatibility with a wide range of Cummins engines, and role in ensuring secure and efficient connections make it an indispensable part of maintaining vehicle performance and reliability.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.