This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

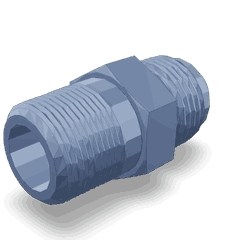

The 3003092 Male Connector, a component manufactured by Cummins, is designed for use in commercial trucks. This connector plays a role in the fluid systems of these vehicles, contributing to the efficiency and reliability of truck operations.

Basic Concepts of Male Connectors

Male connectors are fittings used in fluid systems to join two components together. They feature a protruding end that fits into a corresponding female connector. In automotive and industrial settings, these connectors are vital for the transfer of fluids such as fuel, coolant, and hydraulic fluid. They ensure a secure and leak-free connection, which is essential for the proper functioning of the system 1.

Purpose of the 3003092 Male Connector

The 3003092 Male Connector is designed to facilitate the connection between various components within a truck’s fluid systems. Its role is to provide a reliable interface for the transfer of fluids, ensuring that the system operates efficiently. This connector is integral to maintaining the integrity of the fluid pathways within the truck, contributing to the overall performance and longevity of the vehicle.

Key Features

The 3003092 Male Connector is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The design of the connector includes precision-machined surfaces to ensure a tight seal, minimizing the risk of leaks. Additionally, it features a robust construction that can withstand high pressure and temperature variations commonly encountered in truck fluid systems 2.

Benefits

The use of the 3003092 Male Connector offers several benefits. It contributes to improved system efficiency by providing a secure and leak-free connection. Its durable construction ensures reliability, even in harsh operating conditions. The connector’s design also facilitates easy installation and maintenance, reducing downtime and enhancing the overall efficiency of truck operations 3.

Installation Considerations

When installing the 3003092 Male Connector, it is important to ensure compatibility with other system components. Following manufacturer guidelines for torque specifications and sealing procedures is recommended to achieve a proper fit and seal. Careful attention to these details during installation will help maintain the integrity of the fluid system and ensure optimal performance of the connector.

Troubleshooting and Maintenance

Common issues with male connectors include leaks and corrosion. Regular inspection for signs of wear or damage is recommended to prevent these issues. If a leak is detected, the connector should be inspected for proper seating and sealing. In cases of corrosion, cleaning the connector and applying a compatible sealant may resolve the issue. Adhering to a routine maintenance schedule will help ensure the longevity and optimal performance of the 3003092 Male Connector.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality components and systems. The company offers a wide range of products designed to enhance the performance, efficiency, and reliability of commercial trucks. Cummins’ reputation for quality and innovation makes it a trusted name among fleet operators and maintenance professionals.

Applications of the 3003092 Male Connector

The 3003092 Male Connector is designed to fit seamlessly with a variety of Cummins engine models. This part is essential for ensuring proper fluid flow and system integrity within the engine’s hydraulic or fuel systems.

ISM CM570 and ISM CM570/870

The ISM CM570 and ISM CM570/870 engines benefit from the precise fit of the Male Connector, which is essential for maintaining the efficiency of their hydraulic systems. This connector ensures that the fluid pathways remain unobstructed, contributing to the engine’s overall performance and reliability.

ISM CM876

In the ISM CM876 engine, the Male Connector is integral to the fuel system, providing a secure connection that prevents leaks and maintains system pressure. This is particularly important in the high-performance environment of the ISM CM876.

K38 and K50

For the K38 and K50 engines, the Male Connector plays a key role in the engine’s cooling system. Its design ensures a tight seal, which is vital for preventing coolant loss and maintaining optimal engine temperature.

L10 GAS

In the L10 GAS engine, the Male Connector is used in the fuel system, ensuring that the fuel delivery is consistent and reliable. This part’s precision fit is crucial for the engine’s efficiency and performance.

M11 CELECT PLUS and M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines utilize the Male Connector in their fuel systems. The connector’s design allows for a secure and leak-free connection, which is essential for the engines’ smooth operation.

QSM11 CM570

The QSM11 CM570 engine also relies on the Male Connector for its fuel system. The connector’s compatibility with this engine ensures that the fuel delivery system operates without any issues, contributing to the engine’s overall performance.

V903

Finally, the V903 engine uses the Male Connector in its hydraulic system. The connector’s precise fit is essential for maintaining the system’s integrity and ensuring that the engine operates efficiently.

Role of the 3003092 Male Connector in Engine Systems

The 3003092 Male Connector is integral to the efficient operation of various engine systems by ensuring secure and reliable connections between components. Here’s how it interfaces with the provided components:

Electrical Systems

- Alternator Drive and Alternator Mounting: The Male Connector ensures a robust electrical connection between the alternator and the engine’s electrical system, facilitating efficient power generation and distribution.

Fluid Systems

- Auxiliary Pump Plumbing and Lubricating Oil Plumbing: It provides a dependable link in the fluid pathways, allowing for consistent flow of lubricating oil to critical engine components, thereby enhancing performance and longevity.

- Coolant Heater Plumbing: Ensures that the coolant heater system maintains optimal temperature regulation, which is vital for engine start-up in cold conditions.

- EBM-Pump: Connects the EBM-pump to the engine’s electrical system, ensuring reliable operation of the pump which is essential for maintaining coolant flow.

Heating Systems

- Heater Outlet Hose and Hotstart Plumbing: Facilitates secure connections in the heating systems, ensuring that the engine reaches operating temperature quickly and maintains it efficiently.

- Kim Hotstart and Kim Hotstart Plumbing: Integral to the Kim hotstart system, it ensures that the heating elements receive a stable power supply, crucial for cold-start performance.

Cooling Systems

- Jacket Water Kit and Water Jacket Kit: Plays a key role in the cooling systems by ensuring that all connections within the jacket water systems are secure, allowing for effective heat dissipation from the engine.

Mounting and Structural Components

- Kim Mounting Hotstart: Ensures that the Kim hotstart system is securely connected to the engine, providing stability and reliability during operation.

Oil Systems

- Engine Sump Plumbing and Lubricating Oil (Auxiliary) Pump: Ensures that the auxiliary pump receives a consistent power supply, allowing for efficient oil circulation throughout the engine.

- Oil Filter Lubricating: Secures the connection between the oil filter and the engine’s lubrication system, ensuring that the oil is properly filtered before recirculation.

Power Systems

- AUZ Power: Provides a reliable connection for the AUZ power system, ensuring that all electrical components receive a stable power supply.

Radiator Systems

- Radiator and Radiator Plumbing: Ensures that the radiator system maintains secure connections, allowing for effective cooling of the engine coolant.

Scavenge and Sump Systems

- Scavenge Pump and Sump Pump: Ensures that these pumps are securely connected to the engine’s electrical system, allowing for efficient removal of unwanted fluids from the engine sump.

- Sump Pump Plumbing: Facilitates secure connections within the sump pump system, ensuring consistent operation and fluid removal.

Torque Converter Systems

- Torque Converter Coolant Plumbing: Ensures that the torque converter’s coolant system maintains secure connections, allowing for effective cooling and performance of the torque converter.

Conclusion

The 3003092 Male Connector is a critical component in the fluid systems of commercial trucks, ensuring secure and reliable connections between various engine components. Its durable construction, precision-machined surfaces, and compatibility with a wide range of Cummins engine models make it an essential part for maintaining the efficiency and reliability of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.