This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3002110 Male Connector is a component designed for use in commercial truck systems. Manufactured by Cummins Inc., a well-established name in the automotive industry, this connector plays a role in facilitating the connection between various parts of a truck’s system. Connectors are integral to the operation of heavy-duty trucks, ensuring that different components can communicate and function together efficiently 1.

Basic Concepts of Male Connectors

A male connector is a type of fitting designed to fit into a corresponding female connector. In automotive applications, these connectors are used to join different parts of a system, allowing for the transfer of fluids, electrical signals, or other necessary connections. The design of male connectors typically includes a protruding pin or plug that fits securely into a female counterpart, ensuring a tight and reliable connection 2.

Purpose of the 3002110 Male Connector

The Cummins 3002110 Male Connector is specifically designed to integrate into a truck’s systems, supporting functions such as fluid transfer or electrical connections. Its role is to provide a secure and efficient connection point, ensuring that the systems it is part of operate smoothly and reliably. This connector is engineered to withstand the rigors of heavy-duty truck operations, contributing to the overall performance and reliability of the vehicle 3.

Key Features

The Cummins 3002110 Male Connector is characterized by several key features that enhance its performance and durability. These include a robust material composition that resists wear and corrosion, a design that ensures a secure fit, and unique characteristics that may include specialized coatings or shapes to improve functionality. These features contribute to the connector’s ability to perform reliably in demanding environments.

Benefits

The use of the Cummins 3002110 Male Connector offers several advantages. It contributes to improved system efficiency by ensuring secure and reliable connections. Its design and material composition enhance the reliability of the connections it facilitates, reducing the likelihood of leaks or failures. Additionally, the durability of this connector can lead to cost-effectiveness in maintenance and operation, as it may require less frequent replacement or repair.

Installation Considerations

When installing the Cummins 3002110 Male Connector, it is important to follow guidelines and best practices to ensure a secure and efficient connection. Preparatory steps may include cleaning the connection area and inspecting the connector for any damage. The use of appropriate tools is recommended to facilitate a proper fit, and common pitfalls such as over-tightening should be avoided to prevent damage to the connector or the system it is part of.

Troubleshooting and Maintenance

Identifying and resolving common issues associated with the Cummins 3002110 Male Connector can help maintain its performance and longevity. Regular maintenance routines, such as inspecting for signs of wear or corrosion, can prevent more serious problems. Addressing signs of failure promptly, such as leaks or loose connections, is crucial to maintaining the integrity of the system.

Safety Considerations

When working with the Cummins 3002110 Male Connector, it is important to observe safety protocols. This includes ensuring that the truck is properly shut down and, if applicable, that any electrical systems are disconnected before beginning work. Handling, installation, and maintenance should be conducted with care to avoid injury or damage to the connector or surrounding components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the heavy-duty truck sector. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles.

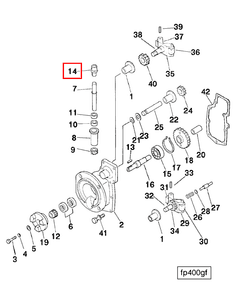

Role of Part 3002110 Male Connector in Engine Systems

The part 3002110 Male Connector is integral to the seamless operation of various engine systems. It facilitates the connection between the Fuel Pump and the Variable Speed (VS) system, ensuring efficient fuel delivery tailored to engine demands.

In systems utilizing an Aftercooler with Variable Speed, the Male Connector ensures a secure link between the Aftercooler and the Variable Speed components, optimizing air cooling and enhancing engine performance.

When interfacing with the Code Fuel system, the Male Connector plays a pivotal role in transmitting data between the Fuel Pump and the Engine Control Unit (ECU), allowing for precise fuel management and adjustments based on real-time engine conditions.

In configurations where the Fuel Pump & Drive (EFC) is employed, the Male Connector ensures a robust connection, facilitating the transfer of mechanical drive from the engine to the fuel pump, guaranteeing consistent fuel pressure and flow.

For engines equipped with a Throttle Control, the Male Connector is essential in linking the Throttle Control mechanism with the Fuel Pump, enabling synchronized adjustments to fuel delivery in response to throttle position changes.

In Tune-Up Kits, such as the 430, the Male Connector ensures all components, from the Fuel Pump to the Tachometer, are interconnected, providing a comprehensive solution for engine maintenance and optimization.

Overall, the 3002110 Male Connector is a foundational component in numerous engine systems, ensuring that fuel delivery, air management, and engine controls are harmoniously integrated for optimal performance.

Conclusion

The Cummins 3002110 Male Connector is a vital component in the operation of commercial truck systems, facilitating secure and efficient connections between various parts. Its robust design and durable material composition contribute to the reliability and performance of heavy-duty trucks. Proper installation, maintenance, and adherence to safety protocols are essential to maximize the benefits of this connector.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.