This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

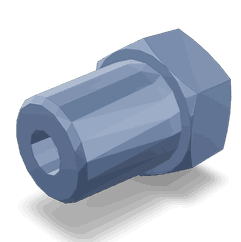

The Cummins 3022865 Female Connector is a specialized component designed for use in heavy-duty truck systems. This connector plays a role in facilitating the connection between various electrical or fluid systems within the truck, ensuring efficient and reliable operation. Its significance lies in its ability to provide a secure and durable link, which is vital for the overall performance and longevity of the truck’s systems 1.

Basic Concepts of Female Connectors

A female connector is a type of fitting used in electrical or fluid systems to receive a corresponding male connector. It functions by providing a secure and sealed connection, which is crucial for the transfer of electricity or fluids without leakage or interruption. In automotive and industrial settings, female connectors are commonly used for their reliability and ease of use, allowing for quick and efficient connections and disconnections as needed 2.

Purpose of the 3022865 Female Connector

The 3022865 Female Connector is specifically designed to play a role in the electrical or fluid systems of a truck. It facilitates the connection between different components, ensuring that electricity or fluids are transferred efficiently and securely. Its integration into the truck’s systems is crucial for maintaining the truck’s operational efficiency and reliability 3.

Key Features

The 3022865 Female Connector boasts several key features that enhance its functionality. These include a robust material composition, typically made from high-quality plastics or metals, ensuring durability and resistance to wear and tear. Its design elements, such as a secure locking mechanism and sealed connection, contribute to its reliability and efficiency in various operating conditions 4.

Benefits

The advantages provided by the 3022865 Female Connector include improved system reliability, as it ensures a secure and sealed connection that prevents leaks and interruptions. Its ease of installation makes it a convenient choice for maintenance and repair tasks. Additionally, its durability under various operating conditions ensures long-term performance and reduces the need for frequent replacements.

Installation Process

To install the 3022865 Female Connector, begin by ensuring that the area where the connector will be installed is clean and free of debris. Use the appropriate tools to connect the female connector to its corresponding male connector, ensuring a secure fit. Follow the manufacturer’s guidelines for any additional components or steps required for a successful installation.

Troubleshooting Common Issues

Common problems that may arise with the 3022865 Female Connector include loose connections, leaks, or damage to the connector. To address these issues, first, ensure that the connector is securely fastened. If leaks are present, check for any damage to the connector or seals and replace if necessary. Regular inspection and maintenance can help prevent these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the 3022865 Female Connector, regular maintenance practices are recommended. These include periodic inspection for signs of wear or damage, cleaning the connector and surrounding area to prevent debris buildup, and ensuring that all connections are secure and tight. Following these practices can help maintain the connector’s efficiency and reliability.

Safety Considerations

When working with the 3022865 Female Connector, it is important to observe electrical safety guidelines and proper handling procedures. Ensure that the truck’s power is off before beginning any work on the electrical system. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Always follow the manufacturer’s safety guidelines and recommendations.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and industrial sectors. Its extensive product range includes engines, powertrains, and related components, serving a wide array of industries and applications.

Cummins Female Connector 3022865 Compatibility with Engine Models

The Cummins Female Connector part number 3022865 is designed to integrate seamlessly with a variety of engine models, ensuring compatibility and reliability across different applications. This part is engineered to meet the stringent demands of heavy-duty operations, providing a robust connection for fluid transfer and management.

K19 and N14 MECHANICAL Engines

The K19 and N14 MECHANICAL engines, both known for their durability and performance, benefit from the precise fit and functionality of the 3022865 connector. This part ensures that fluid lines are securely attached, minimizing the risk of leaks and maintaining system integrity under high-pressure conditions.

NH/NT 855 Engines

The NH/NT 855 engines, recognized for their efficiency and power, also utilize the 3022865 connector. This part’s design allows for easy installation and maintenance, crucial for the demanding environments these engines operate in. The connector’s compatibility with the NH/NT 855 ensures that fluid pathways remain uninterrupted, contributing to the engine’s overall performance and longevity.

V903 Engines

The V903 engine, another high-performance model, is also compatible with the 3022865 connector. This part’s precision engineering ensures that it fits perfectly within the V903’s fluid management system, providing a reliable connection that can withstand the rigors of continuous operation. The compatibility of the 3022865 connector with the V903 engine enhances the engine’s operational efficiency and reliability.

Role of Part 3022865 Female Connector in Engine Systems

The part 3022865 Female Connector is integral to the efficient operation and integration of various components within engine systems. Its application spans across multiple subsystems, ensuring seamless connectivity and functionality.

Turbocharger Systems

In turbocharger setups, the Female Connector is often used in the turbocharger plumbing to join various hoses and pipes that facilitate the flow of coolant, oil, or other fluids. It ensures a secure and leak-proof connection between the turbocharger and its associated components, such as the turbocharger drain plumbing. This is vital for maintaining the turbocharger’s performance and longevity.

Aftercooler Integration

The Female Connector plays a significant role in the aftercooler arrangement. It is used to connect the aftercooler to the turbocharger and other related components, ensuring that the air cooling process is efficient and that there are no leaks in the system. This helps in optimizing the air temperature before it enters the engine, thereby enhancing overall engine performance.

Turbocharger Mounting and Assembly

When it comes to the turbocharger mounting and turbocharger assy., the Female Connector is used to link various parts of the turbocharger system. Whether it’s connecting the turbocharger and mounting components or integrating the turbocharger conversion kit, this connector ensures that all parts are securely fastened, reducing the risk of disconnections or failures.

Instruction Panel Assembly

In the instruction panel assembly, the Female Connector may be used to link sensors, gauges, or other monitoring devices to the main system. This ensures that all readings are accurately transmitted, allowing for real-time monitoring and adjustments.

VT903 Short Block Kit

Within the VT903 short block kit, the Female Connector is employed to join various fluid lines and sensors. This ensures that all components within the short block kit operate in unison, contributing to the engine’s overall efficiency and reliability.

Turbocharger Plumbing and Drain Systems

In turbocharger plumbing and turbocharger drain plumbing, the Female Connector is essential for creating a robust and leak-free system. It connects the turbocharger to the drain lines, ensuring that any excess fluids are properly channeled away, preventing potential damage to the engine components.

Turbo Location and Turbo/Mtg.

For the turbo location and turbo/mtg. (turbo mounting), the Female Connector ensures that all fluid lines and electrical connections are securely in place. This is particularly important in high-performance engines where precision and reliability are paramount.

Conclusion

In summary, the part 3022865 Female Connector is a versatile component that enhances the connectivity and functionality of various engine systems, ensuring they operate efficiently and reliably. Its robust design, ease of installation, and compatibility with a wide range of engine models make it an essential part for maintaining the performance and longevity of heavy-duty truck systems.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.